Method for decolorization of pyroligneous liquor and preparation of calcium magnesium acetate based on catalytic ozonation

A technology of calcium magnesium acetate and ozone oxidation, applied in magnesium oxide, chemical instruments and methods, calcium/strontium/barium oxide/hydroxide, etc., can solve the problem of high cost, achieve high comprehensive utilization rate, and shorten decolorization The effect of simple time and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

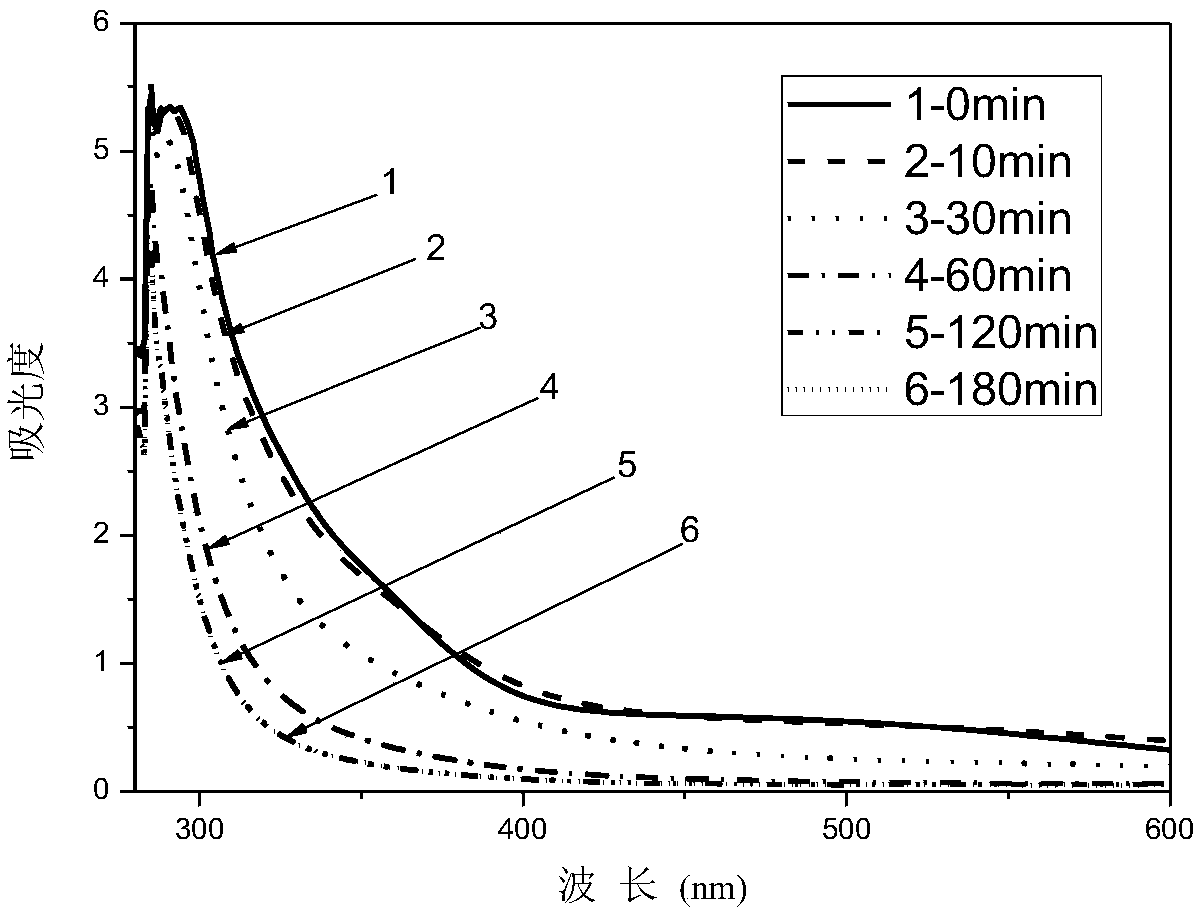

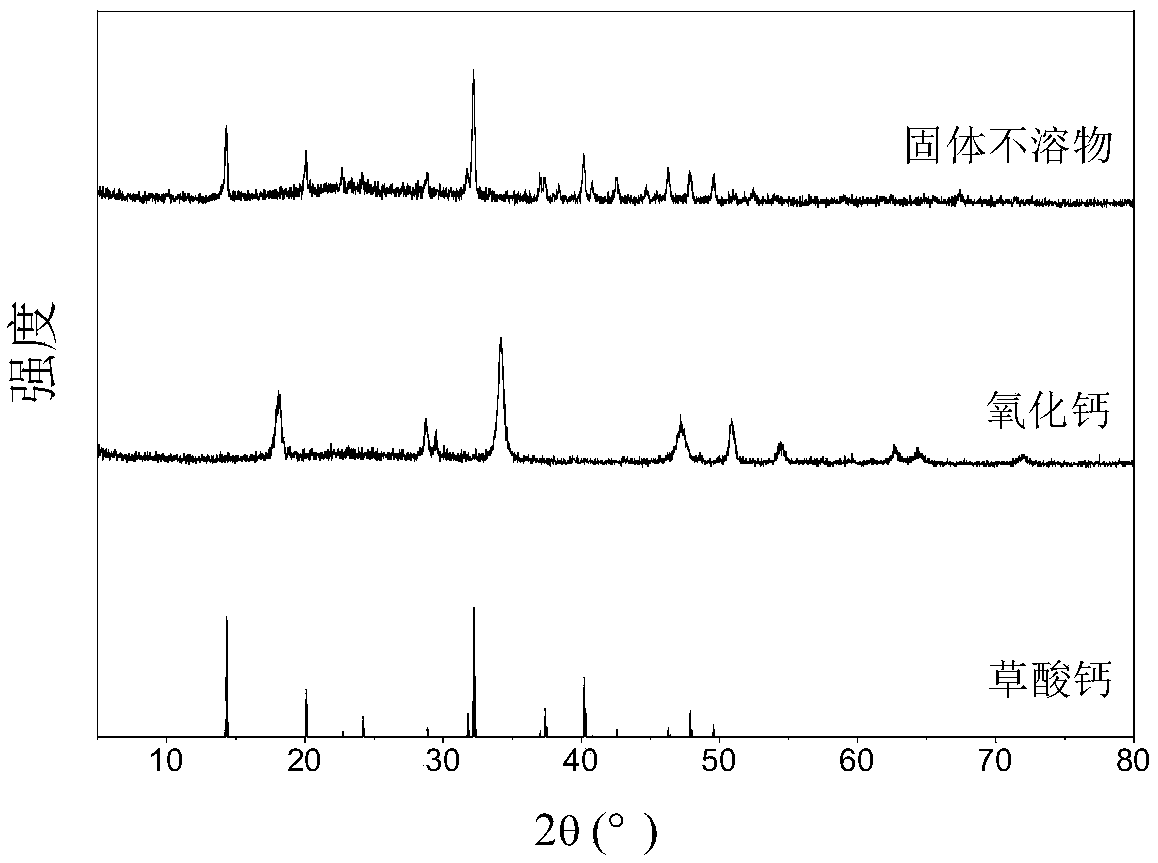

Embodiment 1

[0024] Add calcium oxide to the wood vinegar, stir evenly at room temperature, and react for 1.5 hours to make the pH value 7.5. The insolubles were removed by filtration to obtain a dark brown wood vinegar conversion solution. Add 1g of calcium oxide (corresponding to 4g / L) to 250mL of wood vinegar conversion liquid, and stir, and measure its pH value to be 9.5. Pass into ozone to the wood vinegar conversion liquid that obtains above, it is the ozone and the oxygen mixed gas that the ozone generator produces, wherein O 3 Concentration is 90mg / L, and flow velocity is 200mL / min, and this mixed gas continuously bubbles into wood vinegar conversion liquid through the porous glass membrane at the bottom of the reactor. With the prolongation of ozone time, the color of wood vinegar conversion solution gradually changed from dark brown to light yellow or nearly colorless. figure 1 It is a photograph diagram of the degradation effect of the wood vinegar liquid conversion solution o...

Embodiment 2

[0027] Add magnesium oxide to the wood vinegar, stir evenly at room temperature, and react for 2 hours to make the pH value 8.0. The insolubles were removed by filtration to obtain a dark brown wood vinegar conversion solution. Add 2g of magnesium oxide (equivalent to 8g / L) to 250mL of wood vinegar conversion solution, and stir, and measure its pH to be 10.0. Pass into ozone to the wood vinegar conversion liquid that obtains above, it is the ozone and the oxygen mixed gas that the ozone generator produces, wherein O 3 Concentration is 100mg / L, and flow velocity is 500mL / min, and this mixed gas is continuously bubbled into wood vinegar conversion liquid through the porous glass membrane at the bottom of the reactor. After 4 hours of reaction, the decolorization was completed, and the pH value of the wood vinegar conversion solution was tested to be 7.8, which was close to neutral. The magnesium acetate aqueous solution was directly obtained by suction filtration, and the nearl...

Embodiment 3

[0029] Add calcium hydroxide to the wood vinegar, stir evenly at room temperature, and react for 1 hour to make the pH value 7.0. The insolubles were removed by filtration to obtain a dark brown wood vinegar conversion liquid. Add 2.5g of calcium hydroxide (equivalent to 10g / L) to 250mL of wood vinegar conversion liquid, and stir, and measure its pH value to be 10.8. Pass into ozone to the wood vinegar conversion liquid that obtains above, it is the ozone and the oxygen mixed gas that the ozone generator produces, wherein O 3 The concentration is 90mg / L, and it is continuously bubbled into the wood vinegar conversion liquid through the porous glass membrane at the bottom of the reactor at a flow rate of 400mL / min. After 3 hours of reaction, the pH value of the wood vinegar conversion liquid is 7.5, close to Neutral, directly obtain calcium acetate brine solution by suction filtration, and further obtain nearly white calcium acetate solid powder by spray drying. The solid pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com