Room temperature curing agent for high-temperature-resistant organosilicon materials, preparation method and applications thereof

A room temperature curing agent and silicone technology, applied in the field of room temperature curing agents, can solve the problems of small contact probability of reaction raw materials, increase material cost, unstable product structure, etc., and achieve mass transfer and heat transfer control and increase contact area. and time, the effect that is beneficial to the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0040] The experimental methods used in the following examples are conventional methods unless otherwise specified;

[0041] The reagents and materials in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

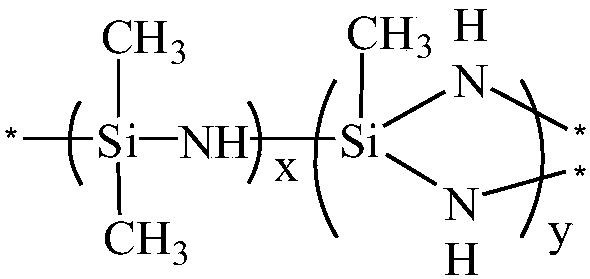

[0043] 600L of petroleum ether (boiling point 30-60°C) was dried through molecular sieves and added into a 1000L reactor through a metering pump, and 100kg of dimethyldichlorosilane and 60kg of methyltrichlorosilane were added to the reactor through the frequency control of the metering pump. Silane, start the stirring of the reactor at 5000rpm, control the temperature in the reactor at -20°C through a refrigerator, dry the ammonia gas through a molecular sieve, and then enter the reactor through mass flow meter control, and pass through 5 inlets arranged around the stirring shaft. The pores enter the reaction system in the form of microbubbles under the air pressure of 3MPa. 10kg of ceramic balls are placed in the reactor to break the ammonium chloride p-dimethyldichlorosilane and methyltrichlorosilane produced in situ. And the resulting polymethylsilazane coating. After 24 hours, no ammonia gas can be detected in the tail gas, and the reaction system stops passing ammonia. D...

Embodiment 2

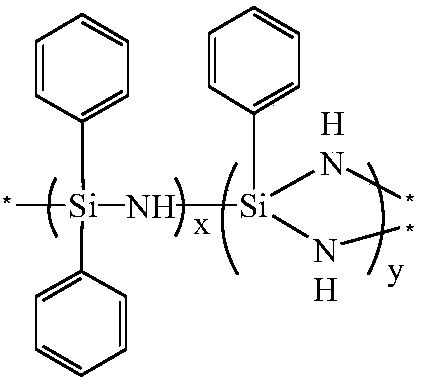

[0048] Put 1200L of ethylene glycol dimethyl ether into a 2000L reactor through a metering pump after drying through molecular sieves, add 200kg of diphenyldichlorosilane and 200kg of phenyltrichlorosilane into the reactor through the frequency control of the metering pump, and start The stirring of the reaction kettle is at 8000rpm, and the temperature inside the reaction kettle is controlled at 80°C by heating. The ammonia gas is dried through molecular sieves and then controlled by a mass flow meter to enter the reaction kettle. There are 10 air inlet holes arranged around the stirring shaft at a temperature of 10MPa. Under the assistance of air pressure, it enters the reaction system in the form of microbubbles. 30kg of ceramic balls are placed in the reactor to break the ammonium chloride p-diphenyldichlorosilane, phenyltrichlorosilane and polyphenylene chloride generated in situ. Coating with silazane. The reaction system stopped passing ammonia after 16 hours when no am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com