Two-step method for preparing modified urea-formaldehyde glue for environment-friendly artificial board

An environmentally friendly wood-based panel and modified urea-formaldehyde technology, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve problems such as adhesive performance differences and complex reaction processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

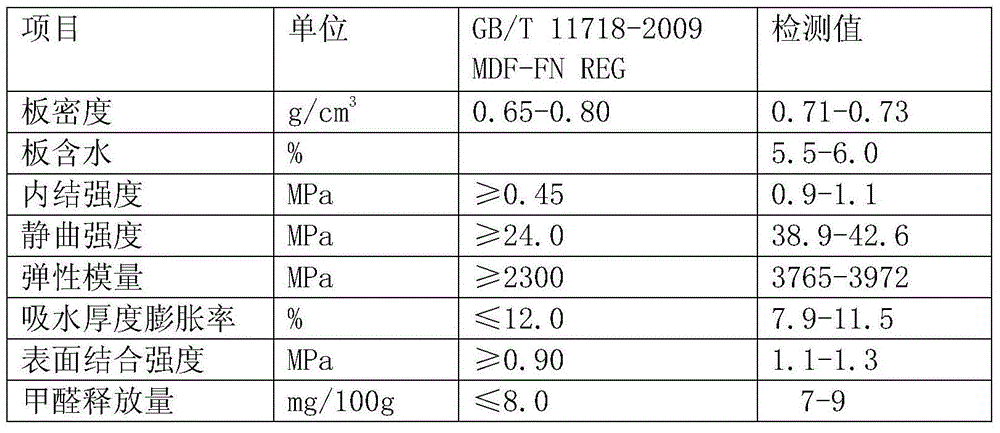

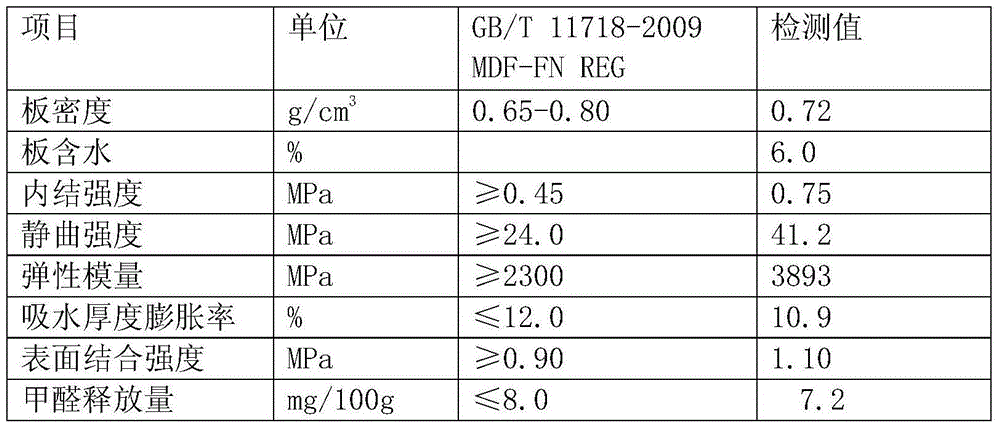

Embodiment 1

[0018] 1. Formula: 1500kg of industrial grade formaldehyde solution (mass concentration 37%), 1025kg of agricultural urea, 25kg of industrial grade melamine, appropriate amount of sodium hydroxide and formic acid, and 25% of the used sodium hydroxide aqueous solution mass concentration.

[0019] 2. Preparation process

[0020] Put all the formaldehyde aqueous solution into the reaction kettle, start the agitator to start heating, stop heating when the temperature rises to 40°C, and adjust the pH value to 5.0 with sodium hydroxide aqueous solution;

[0021] Add the first batch of urea 445kg and all the melamine, continue to heat up to 70°C, stop heating, add formic acid to adjust the pH value to 4.8; then raise the temperature naturally and maintain it at 90±3°C; Form in water, when the reactant drops into water with a water temperature of 42°C, it becomes white mist, which is the first end point;

[0022] Use sodium hydroxide aqueous solution to adjust the pH to 6.5, add th...

Embodiment 2

[0031] 1. Formula: 1200kg of industrial grade formaldehyde solution (mass concentration 37%), 840kg of agricultural urea, 10kg of industrial grade melamine, appropriate amount of sodium hydroxide and formic acid, and 30% of the used sodium hydroxide aqueous solution mass concentration.

[0032] 2. Preparation process

[0033] Put all the formaldehyde aqueous solution into the reaction kettle, start the agitator to start heating, stop heating when the temperature rises to 40°C, and adjust the pH value to 5.2 with sodium hydroxide aqueous solution;

[0034] Add the first batch of urea 360kg and all the melamine, continue to heat up to 70°C, stop heating, add formic acid to adjust the pH value to 4.6; then raise the temperature naturally and maintain it at 90±2°C; Form in water, when the reactant drops into water at a temperature of 40°C, it becomes white mist, which is the first end point;

[0035] Use sodium hydroxide aqueous solution to adjust the pH to 6.3, add the second...

Embodiment 3

[0044] 1. Formula: 1150kg of industrial grade formaldehyde solution (mass concentration 37%), 850kg of agricultural urea, 32kg of industrial grade melamine, appropriate amount of sodium hydroxide and formic acid, and 28% of the used sodium hydroxide aqueous solution mass concentration.

[0045] 2. Preparation process

[0046] Put all the formaldehyde aqueous solution into the reaction kettle, start the agitator to start heating, stop heating when the temperature rises to 40°C, and adjust the pH value to 4.8 with sodium hydroxide aqueous solution;

[0047] Add the first batch of urea 360kg and all the melamine, continue to heat up to 70°C, stop heating, add formic acid to adjust the pH value to 4.5; then raise the temperature naturally and maintain it at 90±3°C; Form in water, when the reactant drops into water at a temperature of 45°C, it becomes white mist, which is the first end point;

[0048] Use sodium hydroxide aqueous solution to adjust the pH to 6.2, add the second ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com