A method and system for detecting that flow rate of high-temperature molten fluid

A fluid velocity, high temperature melting technology, applied in liquid/fluid solid measurement, measurement flow/mass flow, measurement capacity, etc., can solve the problem of low detection accuracy of molten fluid flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

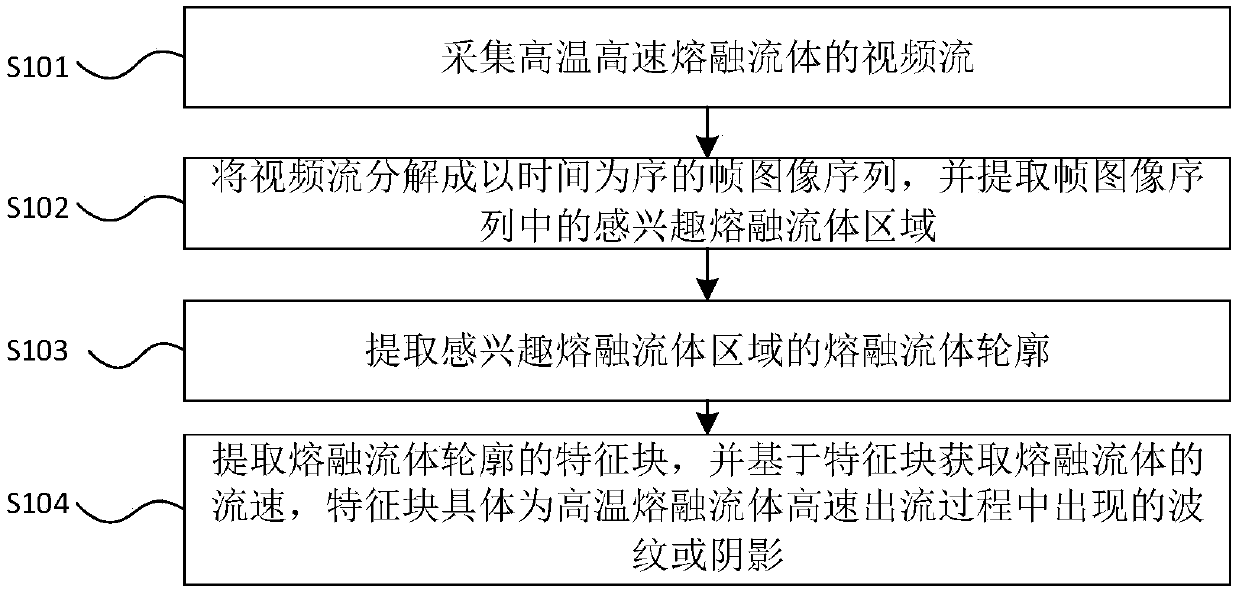

[0088] refer to figure 1 , the method for detecting the flow rate of a high-temperature molten fluid provided in Embodiment 1 of the present invention includes:

[0089] Step S101, collecting video streams of high-temperature and high-speed molten fluid;

[0090] Step S102, decomposing the video stream into time-ordered frame image sequences, and extracting the molten fluid region of interest in the frame image sequences;

[0091] Step S103, extracting the molten fluid profile of the molten fluid region of interest;

[0092] Step S104, extracting feature blocks of the outline of the molten fluid, and obtaining the flow velocity of the molten fluid based on the feature blocks, specifically, the feature blocks are ripples or shadows that appear during the high-speed outflow of the high-temperature molten fluid.

[0093] The method for detecting the flow velocity of the high-temperature molten fluid provided by the embodiment of the present invention collects the video stream o...

Embodiment 2

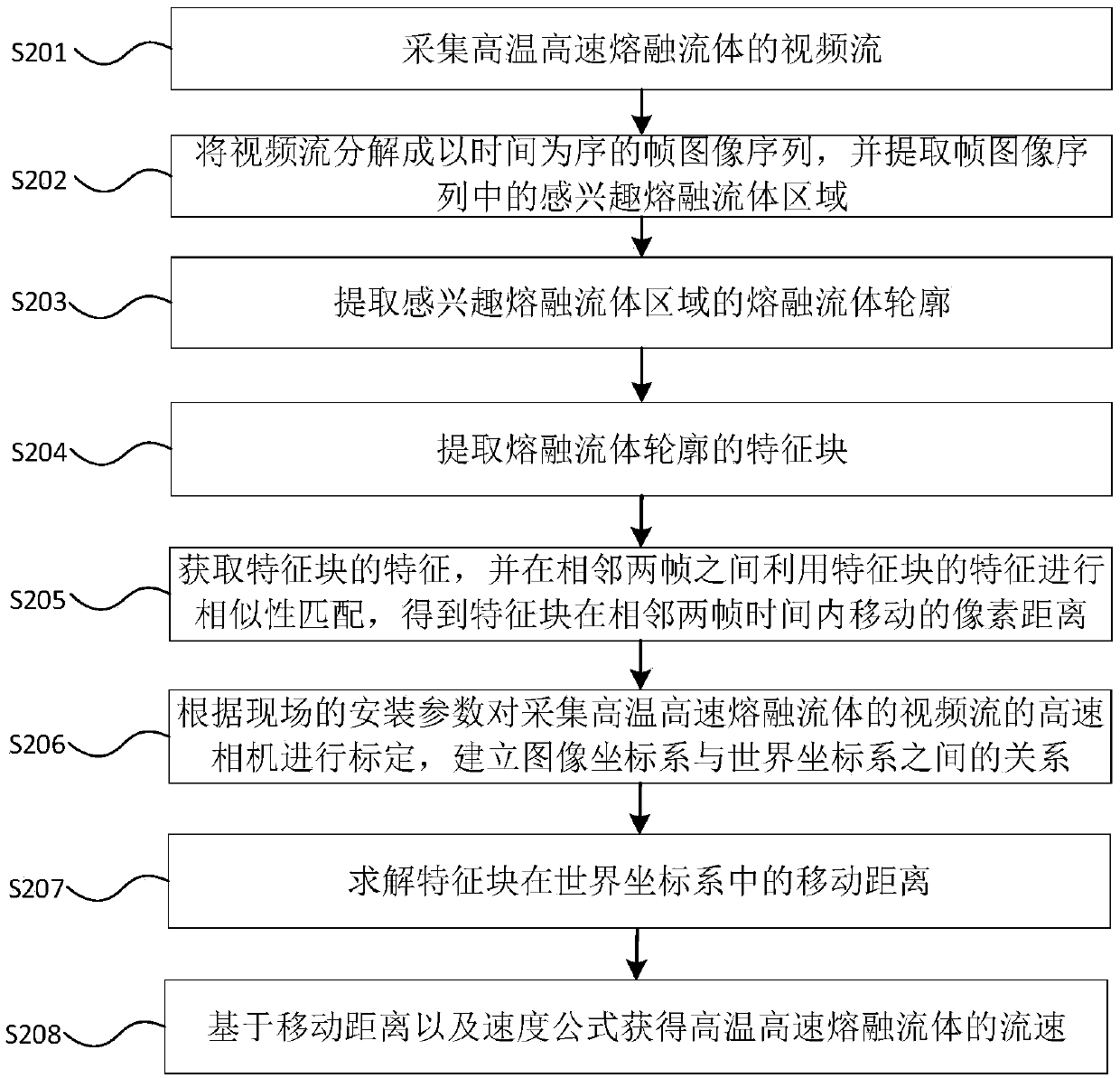

[0096] refer to figure 2 , the method for detecting the flow rate of a high-temperature molten fluid provided in Embodiment 2 of the present invention, comprising:

[0097] Step S201, collecting video streams of high-temperature and high-speed molten fluid.

[0098] Specifically, in the embodiment of the present invention, a video stream of high-temperature and high-speed melting fluid is collected by a high-speed camera.

[0099] Step S202, decomposing the video stream into time-ordered frame image sequences, and extracting the molten fluid region of interest in the frame image sequences.

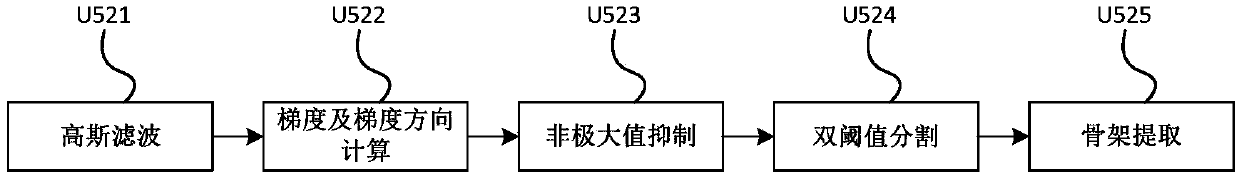

[0100] Specifically, in this embodiment, after the video stream information of the high-temperature and high-speed melting fluid object is collected by a high-speed camera; Fluid region; then, image enhancement operation is performed on the region of interest and the contour of the molten fluid feature block is extracted by a single-pixel contour extraction module to obtain a binary fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com