A detection device for molten iron flow rate based on polarization characteristics

A technology of flow velocity detection and polarization characteristics, which is applied in the directions of measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., and can solve the problem of low accuracy of molten iron flow velocity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

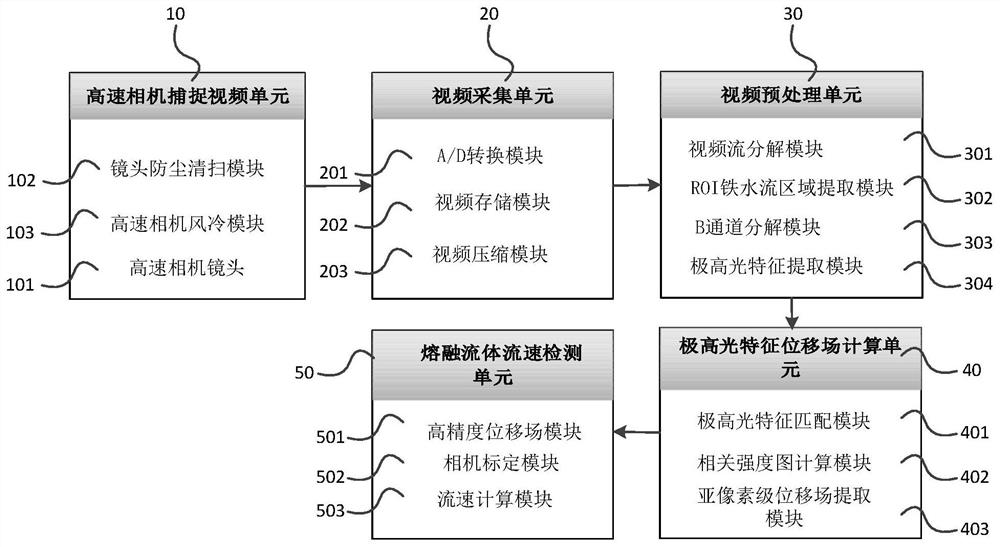

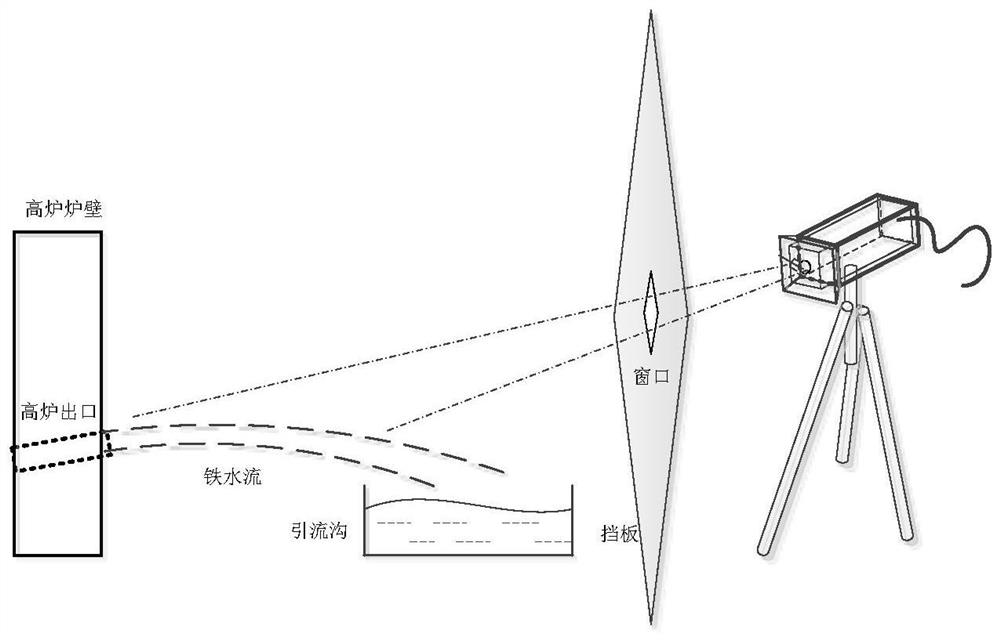

[0072] refer to figure 1 The molten iron flow rate detection device based on polarization characteristics provided by Embodiment 1 of the present invention includes a high-speed camera video capture unit 10, a video acquisition unit 20 sequentially connected to the high-speed camera video capture unit 10, a video preprocessing unit 30, and an extremely high light characteristic Displacement field calculation unit 40 and molten iron flow velocity detection unit 50, wherein:

[0073] A high-speed camera video capture unit 10, used to collect high frame rate video stream information of the molten iron flow at the blast furnace taphole;

[0074] The video acquisition unit 20 is used to perform analog-to-digital conversion, storage and compression on the high frame rate video stream information, thereby obtaining a compressed video stream;

[0075] A video preprocessing unit 30, configured to decompose the compressed video stream into time-ordered frame image groups, and extract t...

Embodiment 2

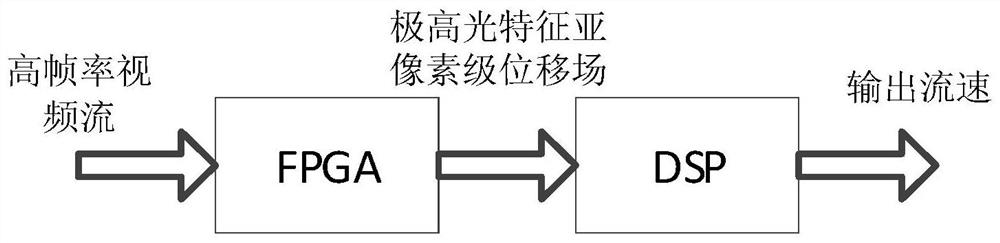

[0120] The molten iron flow rate detection device based on polarization characteristics provided by Embodiment 2 of the present invention includes a high-speed camera video capture unit 10, a video acquisition unit 20 sequentially connected to the high-speed camera video capture unit 10, an integrated video preprocessing unit 30 and a pole The FPGA (Field-Programmable Gate Array Programmable Gate Array) hardware platform of the highlight feature displacement field calculation unit 40 and the multi-DSP hardware platform for integrating the molten iron flow rate detection unit 50, wherein,

[0121] A high-speed camera video capture unit 10, used to collect high frame rate video stream information of the molten iron flow at the blast furnace taphole;

[0122] The video acquisition unit 20 is used to perform analog-to-digital conversion, storage and compression on the high frame rate video stream information, thereby obtaining a compressed video stream;

[0123] The FPGA hardware ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com