Method, device and system for separating and extracting particulate matter from filter substrate

A separation device and technology for particulate matter, which are applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of lack of specific implementation details of the washing method, inability to use organic solvents for washing, and large loss of particulate matter, and improve separation. efficiency and sufficiency, high degree of automation, and the effect of reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

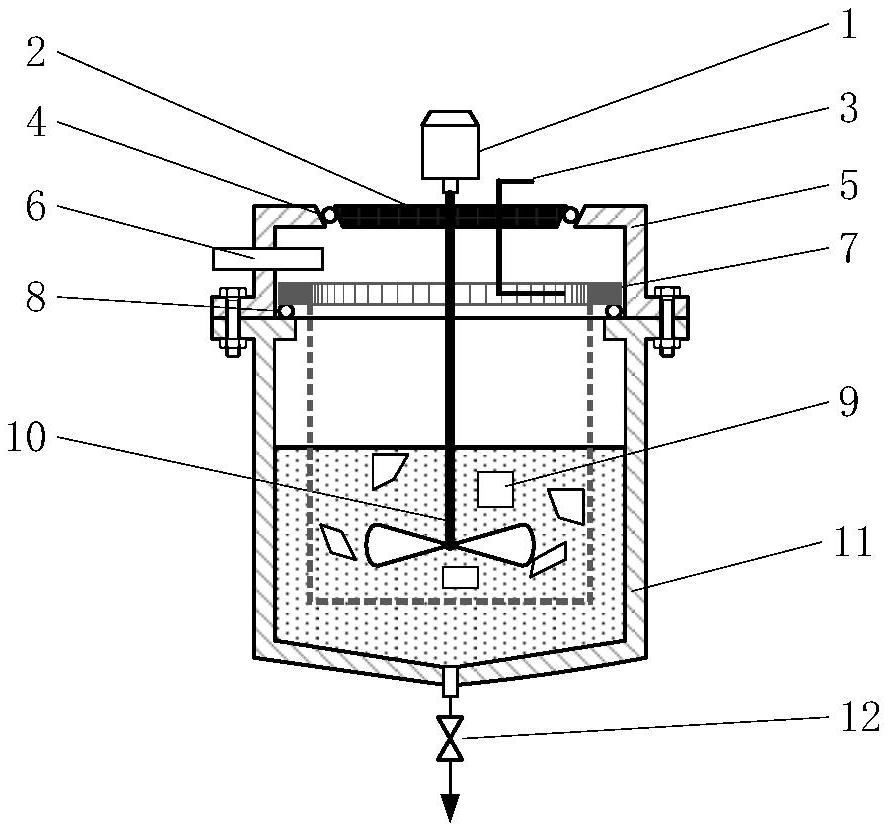

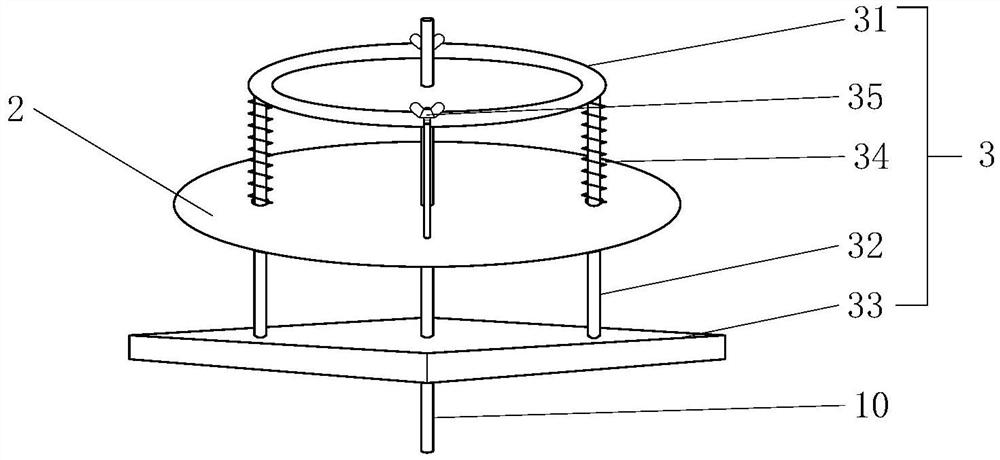

[0094] Embodiment 1: the filter material sheet 9 after sampling in step 1 is 25 grams, adds 3 liters of water, adds surfactant 1.5 milliliters; The stirring speed of step 2 is 800 revolutions per minute, and the stirring time is 3 minutes; The rotating speed of step 3 The speed is 1600 revolutions per minute, and the dehydration time is 1 minute.

Embodiment 2

[0095] Embodiment 2: the filter material sheet 9 after sampling in step 1 is 40 grams, adds 3 liters of water, adds 3 milliliters of surfactants; The stirring speed of step 2 is 400 revolutions per minute, and the stirring time is 5 minutes; The rotating speed of step 3 1400 revolutions per minute, dehydration time is 1 minute.

[0096] After testing, the separation and extraction results of the above-mentioned embodiment 1 and embodiment 2 can all meet the requirement of fully separating and extracting the particulate matter from the filter material matrix.

[0097] When using the above separation device for separation, the dissolved sample of the turbid liquid flowing out from the valve 12 can also be used for the measurement and analysis of constant elements, compounds, and long-lived nuclides, or directly connect the turbid liquid to the separation column, which can be used for the separation of organic components. Enrichment.

[0098] The method, device and system for se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com