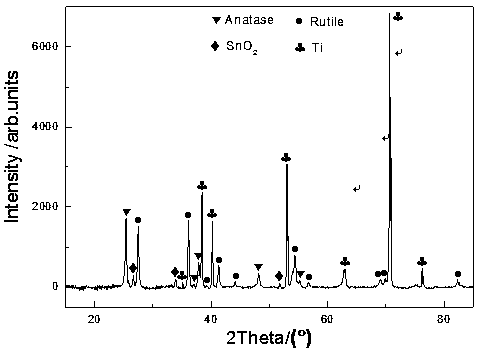

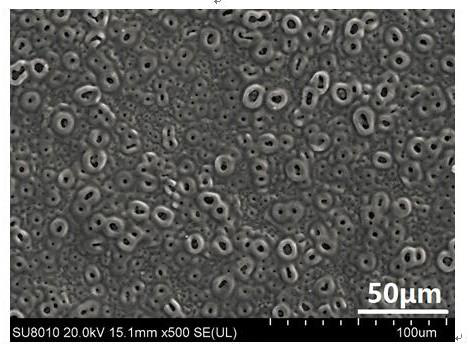

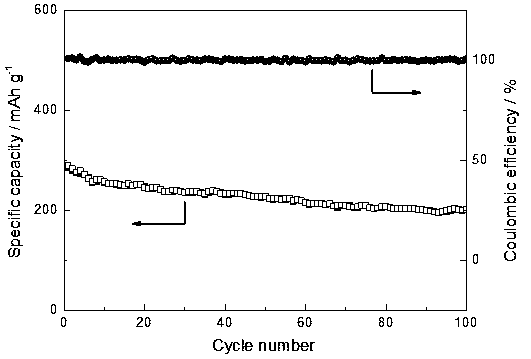

A kind of preparation method of titanium oxide/tin oxide composite film for sodium ion battery negative electrode

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as complex preparation methods, achieve high preparation efficiency, less organic matter, and low equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Prepare the electrolyte used for plasma electrolytic oxidation: the electrolyte is uniformly mixed with phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water, and contains phosphoric acid (85 wt.% ) 1 ml, 1 g sodium silicate, 5 g sodium stannate, and 5 ml glycerol.

[0024] (2) Pretreatment of titanium foam (with a pore size of 1 μm): Ultrasonic cleaning with acetone and alcohol for 10 min, respectively, to remove surface oil, and then dry it.

[0025] (3) Plasma electrolytic oxidation treatment: The pretreated foamed titanium is used as the anode, and the stainless steel is used as the cathode, and they are immersed in the electrolytic tank containing the prepared electrolyte; under normal temperature and pressure conditions, a positive direction is applied between the two electrodes The voltage is 300 V, the negative voltage is 50 V, the pulse frequency is 50 Hz, the processing time is 1 min, and then the power is turned off to prepare a ...

Embodiment 2

[0027] (1) Prepare the electrolyte used for plasma electrolytic oxidation: the electrolyte is uniformly mixed with phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water, and contains phosphoric acid (85 wt.% ) 5 ml, sodium silicate 5 g, sodium stannate 15 g, glycerol 15 ml.

[0028] (2) Pretreatment of titanium foam (with a pore size of 1 μm): Ultrasonic cleaning with acetone and alcohol for 10 min, respectively, to remove surface oil, and then dry it.

[0029] (3) Plasma electrolytic oxidation treatment: The pretreated foamed titanium is used as the anode, and the stainless steel is used as the cathode, and they are immersed in the electrolytic tank containing the prepared electrolyte; under normal temperature and pressure conditions, a positive direction is applied between the two electrodes The voltage is 450 V, the negative voltage is 100 V, the pulse frequency is 150 Hz, the processing time is 10 min, and then the power is turned off to prepare a...

Embodiment 3

[0031] (1) Prepare the electrolyte used for plasma electrolytic oxidation: the electrolyte is uniformly mixed with phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water, and contains phosphoric acid (85 wt.% ) 10 ml, sodium silicate 10 g, sodium stannate 30 g, glycerol 30 ml.

[0032] (2) Pretreatment of titanium foam (with a pore size of 1 μm): Ultrasonic cleaning with acetone and alcohol for 10 min, respectively, to remove surface oil, and then dry it.

[0033] (3) Plasma electrolytic oxidation treatment: The pretreated foamed titanium is used as the anode, and the stainless steel is used as the cathode, and they are immersed in the electrolytic tank containing the prepared electrolyte; under normal temperature and pressure conditions, a positive direction is applied between the two electrodes The voltage is 650 V, the negative voltage is 150 V, the pulse frequency is 300 Hz, the treatment time is 30 min, and then the power is turned off to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com