A kind of process method of extracting and purifying stevioside from stevia

A technology of stevioside and process method, applied in the field of extraction and purification of stevioside, can solve the problems of high cost, unfavorable for industrial production, large consumption of solvent and water, cumbersome production process, etc., and achieves good taste and water solubility, Controllable cost and good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

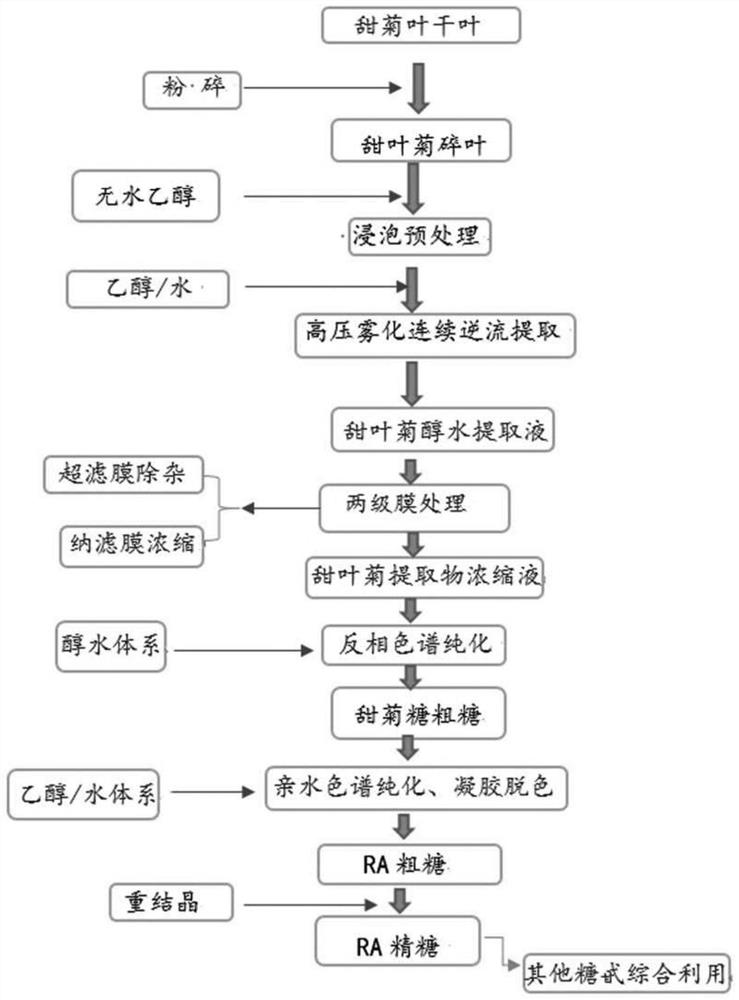

[0037] A process for extracting and purifying stevioside from Stevia, comprising the steps of:

[0038] Pre-treatment of stevia leaves: After drying the stevia leaves, remove impurities such as sand and pulverize, and weigh 1 part of the quality of stevia leaves;

[0039] Soaking pretreatment: Put the crushed stevia leaves in the extraction tank, add 1 part of mass ethanol to soak for two times, each time for 1.5h, the secondary extracts are combined and filtered, and the filtrate is distilled to recover ethanol.

[0040] High-pressure atomization continuous countercurrent extraction: The experiment used continuous countercurrent extraction equipment. Add an appropriate amount of water to the filter residue to disperse and beat the slurry to make a suspension. The material liquid is dispersed into fine droplets by a high-pressure atomizer and sprayed into the countercurrent extraction tank. The 50% ethanol aqueous solution flows into the extraction tank from the bottom under h...

Embodiment 2

[0047] A process for extracting and purifying stevioside from Stevia, comprising the steps of:

[0048] Stevia pretreatment: Stevia leaves are dried to remove impurities such as sand and crushed.

[0049] Soaking pretreatment: Weigh 1 part of stevia leaf crushed leaves and place it in the extraction tank, add 2 parts of edible ethanol according to the weight of stevia leaf, soak at room temperature for 2 hours, centrifugal filter, and distill the filtrate to recover ethanol, and the solid content of the filtrate is 1.6 %, the total steviol glycosides accounted for 0.18% (accounting for the weight of Stevia leaves) in the HPLC test of the ethanol extract, only a small amount of steviol glycosides (about 1.5%) was lost by ethanol extraction, and tannin and pectin could be removed by extraction. , pigments and other impurities, contribute to membrane filtration.

[0050] High-pressure atomization continuous countercurrent extraction: add an appropriate amount of 50% ethanol solu...

Embodiment 3

[0057] A process for extracting and purifying stevioside from Stevia, comprising the steps of:

[0058] Stevia pretreatment: Stevia leaves are dried to remove impurities such as sand and crushed.

[0059] Soaking pretreatment: Weigh 1 part of stevia leaf crushed leaves and put it in the extraction tank, add 5 parts of edible ethanol according to the weight of stevia leaf, soak at room temperature for 2.5h, centrifugal filter, and distill the filtrate to recover ethanol.

[0060] High-pressure atomization continuous countercurrent extraction: Stevia filter residue is added with an appropriate amount of 60% ethanol solution to disperse and beat to make a suspension. The solvent flows into the extraction tank from the bottom under high pressure, the two are fully contacted to make the extraction complete, the ratio of solute to total solvent is 1:10, the pressure of the high-pressure sprayer is 2-4MPa, the flow rate is 200-250L / h, the extraction tank The internal extraction temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com