Cement pipe pile for reinforced photovoltaics using recycled concrete and preparation method thereof

A technology of recycled concrete and cement pipes, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of poor concrete pouring and tamping, poor pile quality, and low compressive strength, and achieve sustainable development and reasonable grading , Reduce the effect of settlement shrinkage and self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

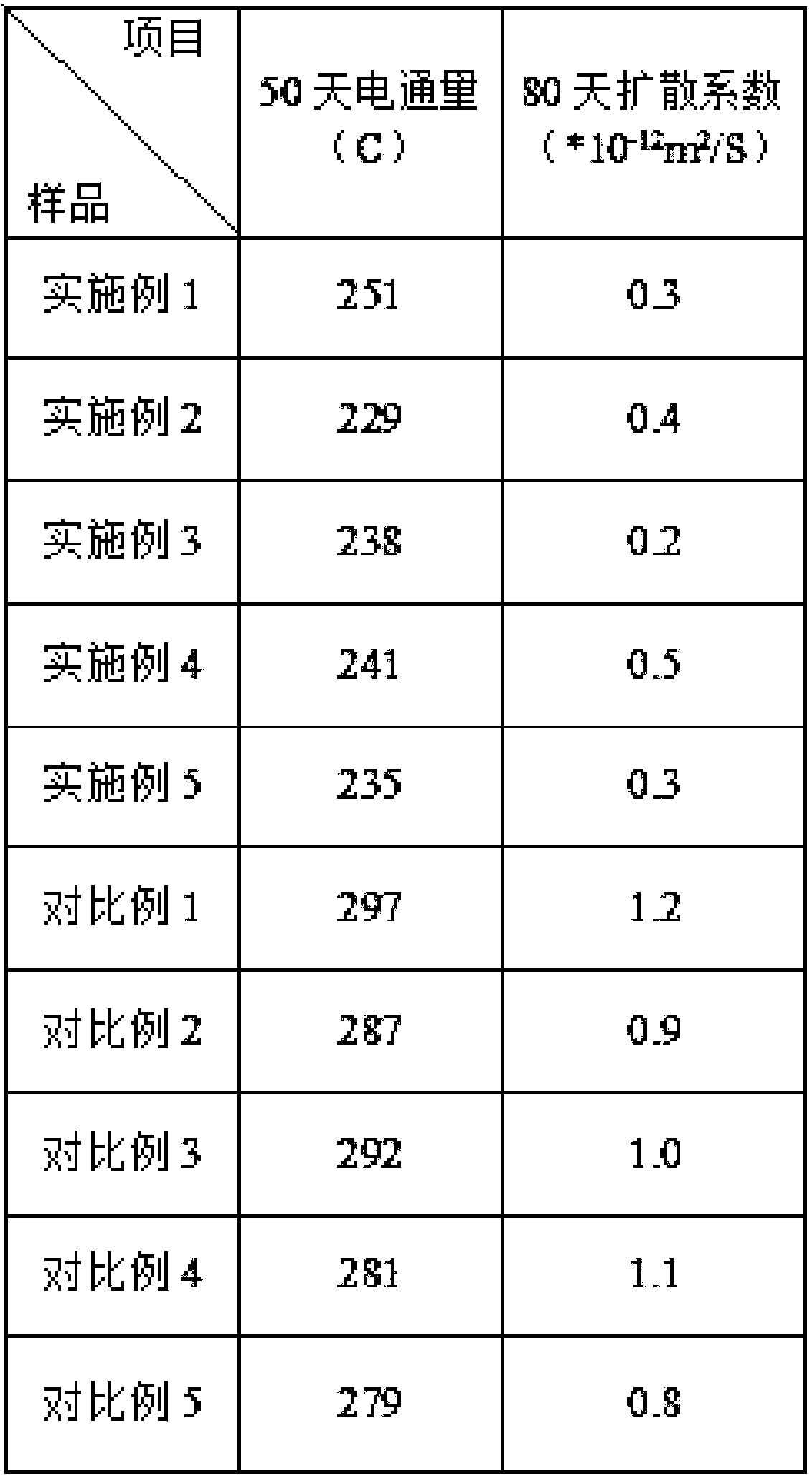

Examples

Embodiment 1

[0057] A reinforced cement pipe pile for photovoltaics using recycled concrete, the cement pipe pile includes the following components in parts by weight: 300 parts of recycled coarse aggregate, 600 parts of recycled fine aggregate, 500 parts of cementitious material, 5 parts of preservative, 5 parts of expansion agent, 3 parts of early strength agent, 10 parts of water reducing agent, 10 parts of auxiliary agent and 100 parts of water.

[0058] The auxiliary agent in the above raw materials is a mixture of ethylene oxide, polyethylene glycol monostearate, nonylphenol polyoxyethylene ether and sodium carboxymethyl cellulose, ethylene oxide, polyethylene glycol monostearate The mass ratio of fatty acid ester, nonylphenol polyoxyethylene ether and sodium carboxymethylcellulose is 1:0.5:0.1:0.1.

[0059] The cementitious material in the above raw materials is a mixture of ordinary Portland cement, calcium sulfate, microsilica and alumina, and the mass ratio of ordinary Portland c...

Embodiment 2

[0074] A reinforced cement pipe pile for photovoltaics using recycled concrete, the cement pipe pile includes the following components in parts by weight: 350 parts of recycled coarse aggregate, 650 parts of recycled fine aggregate, 550 parts of cementitious material, 6 parts of preservative, 8 parts of expansion agent, 5 parts of early strength agent, 12 parts of water reducing agent, 15 parts of auxiliary agent and 150 parts of water.

[0075] The auxiliary agent in the above raw materials is a mixture of ethylene oxide, polyethylene glycol monostearate, nonylphenol polyoxyethylene ether and sodium carboxymethyl cellulose, ethylene oxide, polyethylene glycol monostearate The mass ratio of fatty acid ester, nonylphenol polyoxyethylene ether and sodium carboxymethylcellulose is 1:0.6:0.15:0.15.

[0076] The cementitious material in the above raw materials is a mixture of low-heat Portland cement, gypsum, microsilica and alumina, and the mass ratio of low-heat Portland cement, ...

Embodiment 3

[0091] A reinforced cement pipe pile for photovoltaics using recycled concrete, the cement pipe pile includes the following components in parts by weight: 400 parts of recycled coarse aggregate, 700 parts of recycled fine aggregate, 600 parts of cementitious material, 5-15 parts of preservative 12.5 parts of expansion agent, 6.5 parts of early strength agent, 15 parts of water reducing agent, 20 parts of auxiliary agent and 200 parts of water.

[0092] The auxiliary agent in the above raw materials is a mixture of ethylene oxide, polyethylene glycol monostearate, nonylphenol polyoxyethylene ether and sodium carboxymethyl cellulose, ethylene oxide, polyethylene glycol monostearate The mass ratio of fatty acid ester, nonylphenol polyoxyethylene ether and sodium carboxymethylcellulose is 1:0.65:0.2:0.15.

[0093] The cementitious material in the above raw materials is a mixture of medium heat Portland cement, hemihydrate gypsum, microsilica and alumina, and the mass ratio of medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com