Preparation method and application of amorphous composite electrode for electrocatalytic dechlorination

A composite electrode and amorphous technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low electrode stability, large electrode catalyst loading, high cost, etc., and achieve multiple surface defects , high catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of amorphous composite electrode

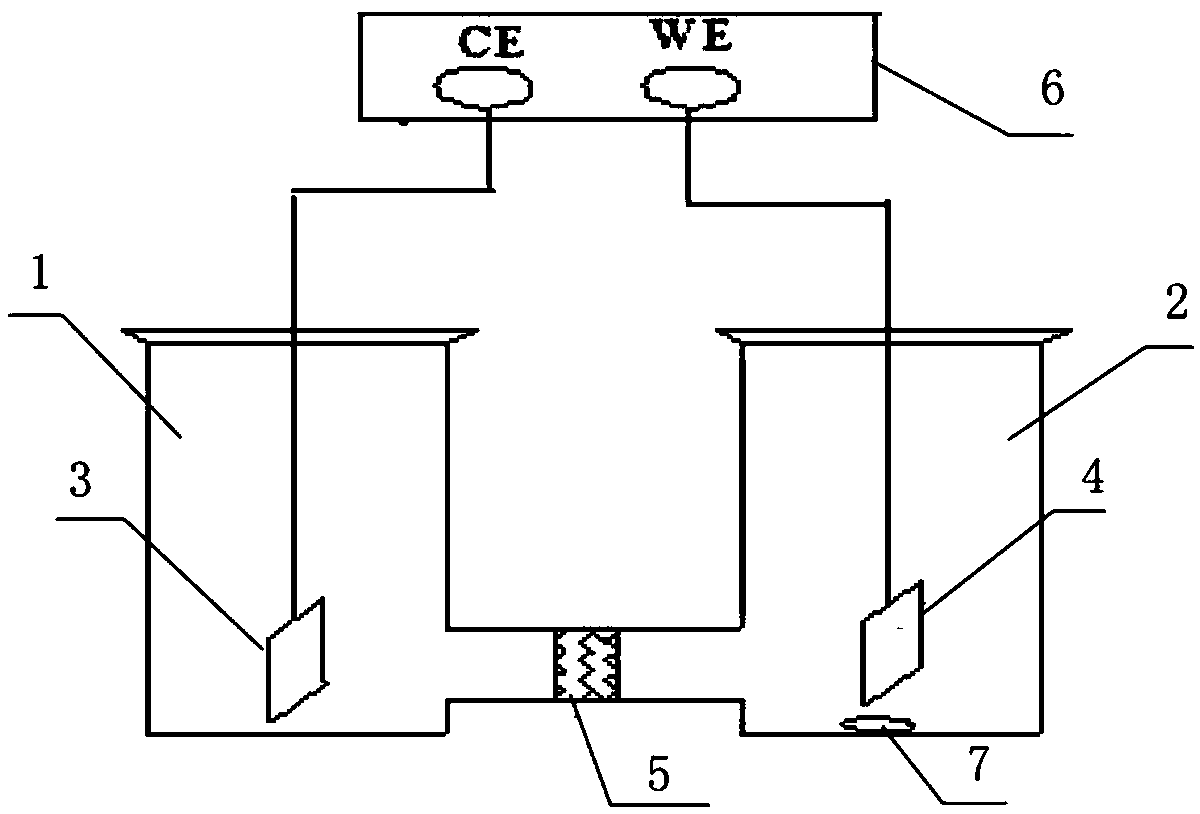

[0033] Foam Ni (20mm×25mm) was put into 0.5mol / L hydrochloric acid and ultrasonically oscillated for 5min to remove impurities. After rinsing with distilled water, put it into absolute ethanol for 10min sonication. After rinsing, ultrasonically 3 times with distilled water and then dried. Weigh 0.20g of RuCl 3 After the powder and 10mL of pyrrole are fully dissolved, the volume is adjusted to a 500ml volumetric flask to make a solution containing N-RuCl 3 Mix the electrolyte solution. The pretreated foamed Ni electrode was used as the cathode, the platinum sheet was used as the anode, and the N-RuCl 3 The solution is an electrolyte, and the current density is 0.2mA / cm 2 , Electrodeposition for 40min, then electrochemical deposition made amorphous Ru-N / foam nickel electrode. like figure 1 Shown is a schematic diagram of the preparation device for the amorphous composite electrode.

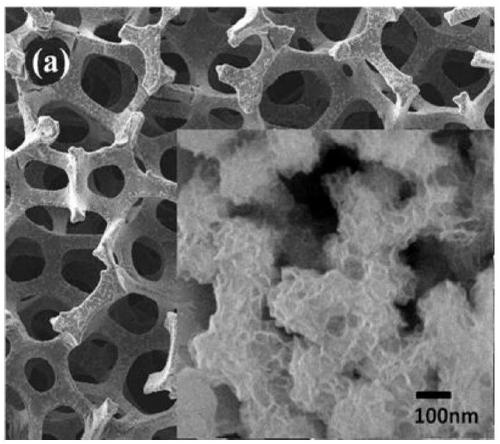

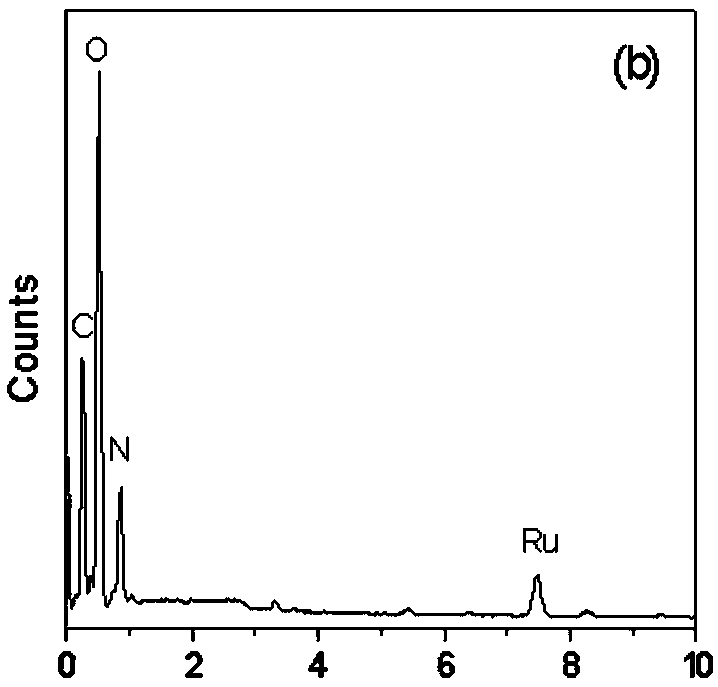

[0034] figure 2 It is the SEM i...

Embodiment 2

[0040] 1. Preparation of amorphous composite electrode

[0041] Soak foamed nickel (20mm×25mm) in 0.5mol / L sulfuric acid and sodium hydroxide solution and oscillate for 5 minutes to remove impurities. Rinse with distilled water and put it in absolute ethanol for 10 minutes. After rinsing, use distilled water to sonicate 3 times Then dry. Weigh 0.1gPdCl 2 Dissolve the powder in water, add a small amount of hydrochloric acid to make PdCl 2 Completely dissolve, then add 3.551g of anhydrous sodium sulfate and 2-5g of boric acid, after fully dissolving, set the volume to 500ml to form a mixed solution with different boron content. The pretreated nickel foam is used as the cathode, the platinum sheet is used as the anode, and the PdCl 2 -B solution is the electrolyte, the current density is 0.2mA / cm 2 , Electrodeposited for 40min, then the Pd-B / foam nickel amorphous composite electrode was prepared by electrochemical deposition.

[0042] Image 6 It is the SEM picture of the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com