Sustained release type tylosin phosphate microcapsule preparation and preparation method thereof

A tylosin phosphate, sustained-release technology, used in microcapsules, antibacterial drugs, capsule delivery, etc., can solve the problems of dose-dependent gastrointestinal disorders, smooth muscle stimulation, tylosin phosphate bitterness, etc. , to achieve the effect of improving drug bioavailability, less toxic and side effects, and improving drug stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of sustained-release tylosin phosphate microcapsule preparation, comprising:

[0040] Mixing and melting step: put the excipients in the formula amount in an emulsification tank, heat and stir until the excipients are completely melted, then add tylosin phosphate into the melted excipients, and then carry out high-speed shearing and stirring to make all the tylosin phosphate Dissolve and form a uniform dispersion system with the auxiliary material melt to obtain a mixed melt;

[0041] Spray condensation granulation step: send the mixed molten liquid to a spray condensation granulation tower, centrifugal spray granulation, and obtain tylosin phosphate microcapsules.

[0042] In the whole process of the present invention, it is prepared by dissolving the tylosin phosphate crude drug in the heated auxiliary material molten liquid, and then preparing it through a spray condensation granulation system. The process can make the main drug uniformly disper...

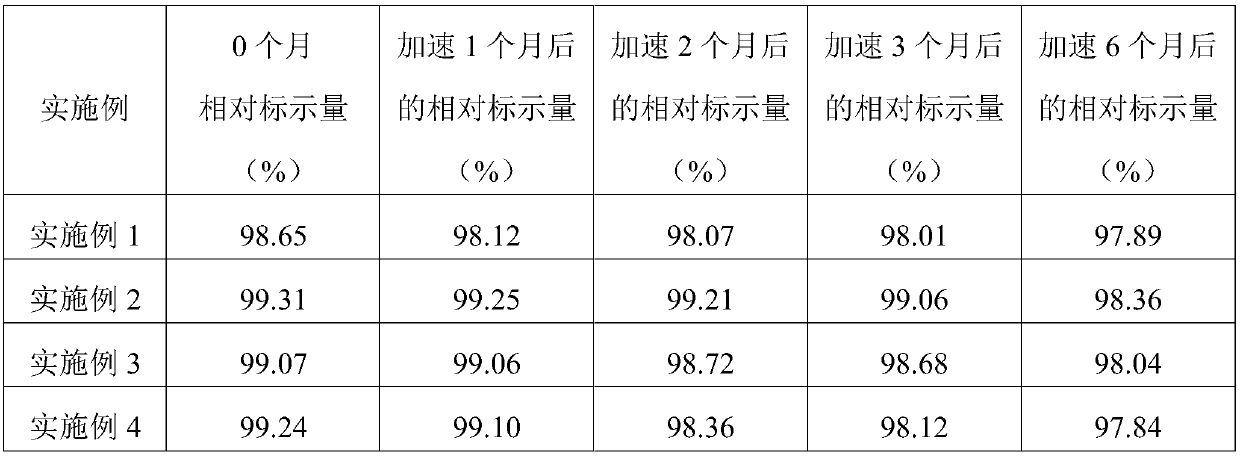

Embodiment 1

[0051] A slow-release type tylosin phosphate microcapsule preparation, prepared according to the following method: Weigh 19.5kg stearyl alcohol, 2.4kg glyceryl monostearate, 1.5kg carnauba wax and emulsify in preheated to 100°C In the tank, continue heating, shearing and stirring (the shearing power is 15kW, and the stirring speed is 1500r / min) so that all the auxiliary materials are melted, and a yellow clear molten liquid is obtained. Under continuous heating at 100°C and shear stirring, 6.6 kg of tylosin phosphate was added, and heating and stirring was continued for 15 minutes to completely dissolve the tylosin phosphate. Before spray cooling and granulation, preheat the centrifugal nozzle for 30 minutes in advance, and turn on the cooling system to cool down in advance (inlet air temperature is 15°C, and outlet air temperature is 25°C). After the nozzle is preheated and the temperature of the cooling tower is lowered to the set value, the rotation speed of the nozzle is s...

Embodiment 2

[0053] A slow-release type tylosin phosphate microcapsule preparation is prepared according to the following method: Weigh 16.8kg stearyl alcohol, 3.0kg glyceryl monostearate, and 3.6kg carnauba wax in a preheated to 110°C In the emulsification tank, continuous heating, shearing and stirring (the shearing power is 20kW, and the stirring speed is 1800r / min) make all the auxiliary materials melt, and obtain a yellow clear molten liquid. Under continuous heating at 110°C and shearing and stirring, 6.6 kg of tylosin phosphate was added, and heating and stirring was continued for 10 minutes to completely dissolve the tylosin phosphate. Before spray cooling and granulation, preheat the centrifugal nozzle for 30 minutes in advance, and turn on the cooling system to cool down in advance (inlet air temperature is 18°C, and outlet air temperature is 28°C). After the nozzle is preheated and the temperature of the cooling tower is lowered to the set value, the rotation speed of the nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com