Walnut polypeptide coffee mate and preparation method thereof

A technology of walnut polypeptide and coffee mate, which is applied in coffee extraction, multi-step food processing, protein composition of vegetable seeds, etc., can solve problems such as single taste and limit the diversification of beverage functions, so as to enhance immunity and maintain intestinal tract Healthy, easy-to-implement process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

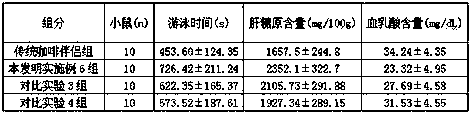

Examples

Embodiment 1

[0041] A walnut polypeptide coffee companion, comprising the following raw materials in parts by weight: 10 parts of walnut oil, 5 parts of walnut polypeptide powder, 1 part of xylitol powder, 1 part of fructooligosaccharide, 10 parts of maltodextrin, casein acid 3 parts of sodium, 0.5 parts of silicon dioxide, 1 part of monoglyceride, 0.1 part of sodium stearoyl lactylate, 0.1 part of sodium tripolyphosphate, 0.5 part of lecithin, 0.1 part of tripolyglycerol monostearate, propylene glycol monostearate 0.5 part of acid ester.

Embodiment 2

[0043] A walnut polypeptide coffee companion, comprising the following raw materials in parts by weight: 30 parts of walnut oil, 10 parts of walnut polypeptide powder, 10 parts of xylitol powder, 10 parts of fructooligosaccharides, 30 parts of maltodextrin, casein acid 8 parts sodium, 2 parts silicon dioxide, 5 parts monoglyceride, 2 parts sodium stearoyl lactylate, 2 parts sodium tripolyphosphate, 3 parts lecithin, 2 parts tripolyglycerol monostearate, propylene glycol monostearate 3 parts of acid ester.

[0044] The walnut oil is produced by low temperature hydraulic pressure, and the low temperature is 20°C.

[0045] Described walnut polypeptide powder adopts following preparation method to obtain:

[0046] Step (A), raw material and crushing: crush the walnut meal powder after low-temperature pressing for oil production or subcritical extraction, pass through a 40-100 mesh sieve, and take the sieved material to obtain the walnut defatted meal powder;

[0047] Step (B), p...

Embodiment 3

[0053] A walnut polypeptide coffee companion, comprising the following raw materials in parts by weight: 20 parts of walnut oil, 6 parts of walnut polypeptide powder, 7 parts of xylitol powder, 8 parts of fructooligosaccharides, 15 parts of maltodextrin, casein acid 5 parts sodium, 1 part silicon dioxide, 4 parts monoglyceride, 1 part sodium stearoyl lactylate, 1 part sodium tripolyphosphate, 2 parts lecithin, 1 part tripolyglycerol monostearate, propylene glycol monostearate 2 parts of acid ester.

[0054] The walnut oil is produced by low-temperature hydraulic pressure, and the low-temperature temperature is 30°C.

[0055] Described walnut polypeptide powder adopts following preparation method to obtain:

[0056] Step (A), raw material and crushing: crush the walnut meal powder after low-temperature pressing for oil production or subcritical extraction, pass through a 40-100 mesh sieve, and take the sieved material to obtain the walnut defatted meal powder;

[0057] Step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com