Preparation method of high-coercivity magnetic nanoparticle suspension

A technology of magnetic nanoparticles and high coercive force, which is applied in the direction of magnetic liquid, inductor/transformer/magnet manufacturing, electrical components, etc., and can solve the problems of large particle size distribution range of nano-alloy particles, difficulty in precise size control, and difficulty in application , to achieve the effect of simple preparation method, low cost and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

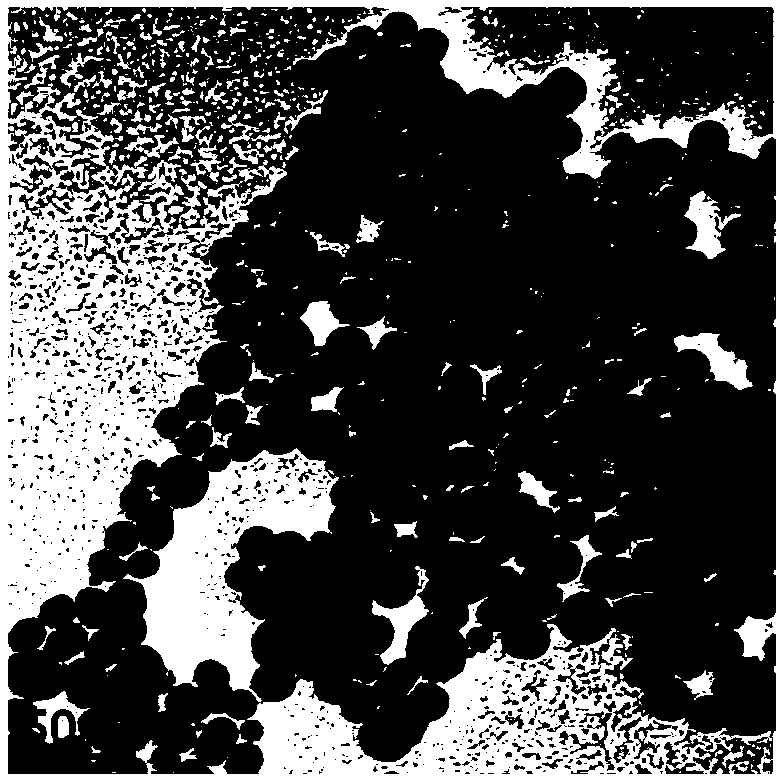

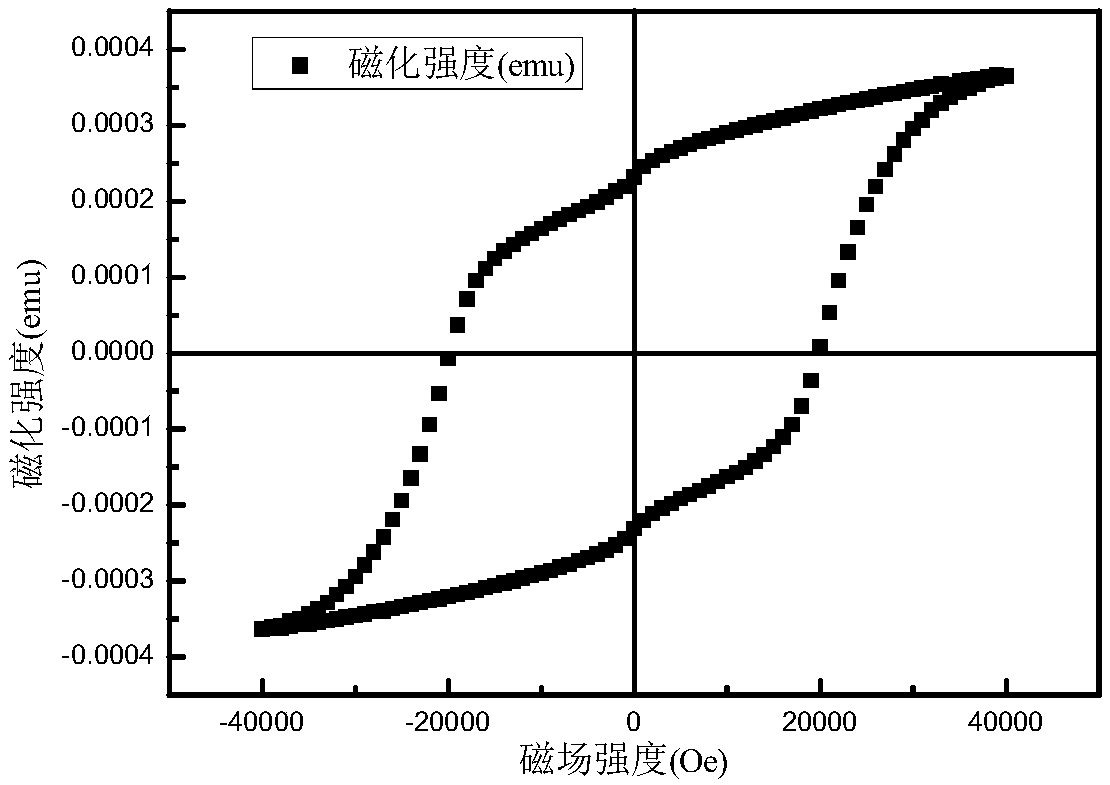

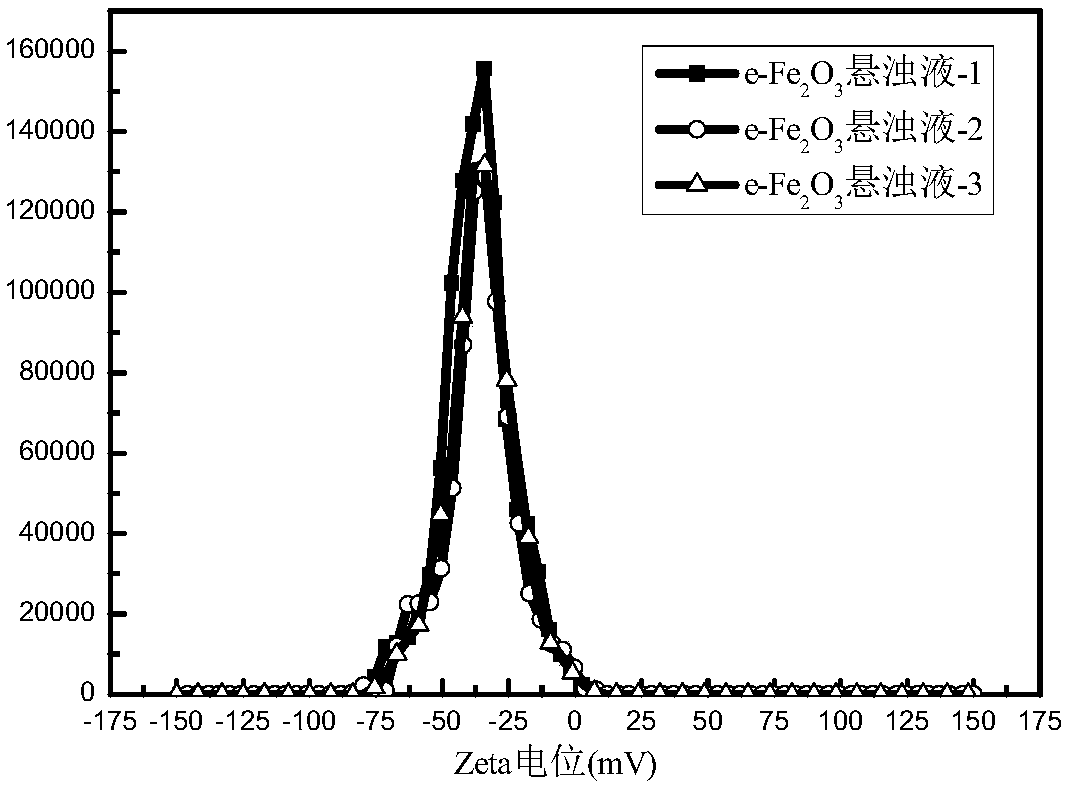

[0033] In the following examples, metal-containing and inorganic mesoporous material colloids were prepared by using the sol-gel method. Ferric nitrate nonahydrate was used as the metal precursor, ethanol aqueous solution was used as the reaction solvent, and ethyl orthosilicate was used as the precursor of the inorganic mesoporous material. The heating rate, constant temperature, and holding time can obtain ε-Fe coated with silicon mesoporous materials. 2 o 3 Magnetic nanoparticles, by controlling the centrifugation rate and ultrasonic time, ε-Fe with a coercive force of 2T, uniform dispersion and stability can be prepared 2 o 3 Magnetic nanoparticle suspension.

[0034] Under the stirring action of a magnetic stirrer, 5.4 mL of deionized water and 26 mL of absolute ethanol were mixed. After 5 minutes, 10.6 g of ferric nitrate nonahydrate was added to the mixed solution. After 5 minutes, mixture A1 was obtained. Keep the rotating speed of the magnetic stirrer at 200r / min, ...

Embodiment 2

[0040] Under the stirring action of a magnetic stirrer, 5.4 mL of deionized water and 26 mL of absolute ethanol were mixed. After 5 minutes, 10.6 g of ferric nitrate nonahydrate was added to the mixed solution. After 5 minutes, mixture A1 was obtained. Keep the rotating speed of the magnetic stirrer at 200r / min, add 20mL tetraethyl orthosilicate dropwise to the mixture A1, and keep it for 20min to obtain a uniformly mixed liquid. The liquid was poured into a closed but not tightly sealed petri dish, and the petri dish was kept in a fume hood for 15 days at a temperature of 23°C to obtain colloids containing Fe and Si. Grind the colloid into particles with a particle size of less than 1 μm in an agate mortar, place the particles in an alumina crucible, put the crucible into a box-type resistance furnace for annealing, first increase the temperature from room temperature to 450 °C at a rate of 200 °C / h, and then Raise to 1000°C at a rate of 80°C / h, and keep at 1000°C for 1 hour ...

Embodiment 3

[0043] Under the stirring action of a magnetic stirrer, 5.4 mL of deionized water and 26 mL of absolute ethanol were mixed. After 5 minutes, 10.6 g of ferric nitrate nonahydrate was added to the mixed solution. After 5 minutes, mixture A1 was obtained. Keep the rotating speed of the magnetic stirrer at 200r / min, add 20mL tetraethyl orthosilicate dropwise to the mixture A1, and keep it for 20min to obtain a uniformly mixed liquid. The liquid was poured into a closed but not tightly sealed petri dish, and the petri dish was kept in a fume hood for 15 days at a temperature of 23°C to obtain colloids containing Fe and Si. Grind the colloid into particles with a particle size of less than 1 μm in an agate mortar, place the particles in an alumina crucible, put the crucible into a box-type resistance furnace for annealing, first increase the temperature from room temperature to 450 °C at a rate of 200 °C / h, and then Raise to 1200°C at a rate of 80°C / h, and keep at 1200°C for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com