Preparation method of zirconium-doped hafnium oxide ferroelectric film, and product and application thereof

A hafnium dioxide and ferroelectric thin film technology, which is applied in circuits, electrical components, gaseous chemical plating, etc., can solve problems such as difficulties in thin film preparation, achieve good distribution uniformity, simple and controllable preparation process, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A 12-inch silicon wafer is placed in a PEALD chamber and heated to 250°C. Introduce gasified hafnium tetramethylethylamino hafnium into the ALD chamber by means of vapor draw, and the introduction time is 5 seconds. After drawing out the excess precursor, fill the ALD chamber with 200 sccm of oxygen, and light the plasma (300W), the duration of the plasma is 5 seconds; after pumping out the by-products, introduce vaporized tetramethylethylamino zirconium into the ALD chamber through steam suction, and the import time is 5 seconds. The ALD chamber is filled with 200 sccm of oxygen, and the plasma (300W) is turned on, and the duration of the plasma is 5 seconds; one cycle of deposition is completed after the by-product is pumped out.

[0042] Repeat this film deposition for a total of 50 cycles. The film was annealed in a chamber at 650°C for 30 minutes.

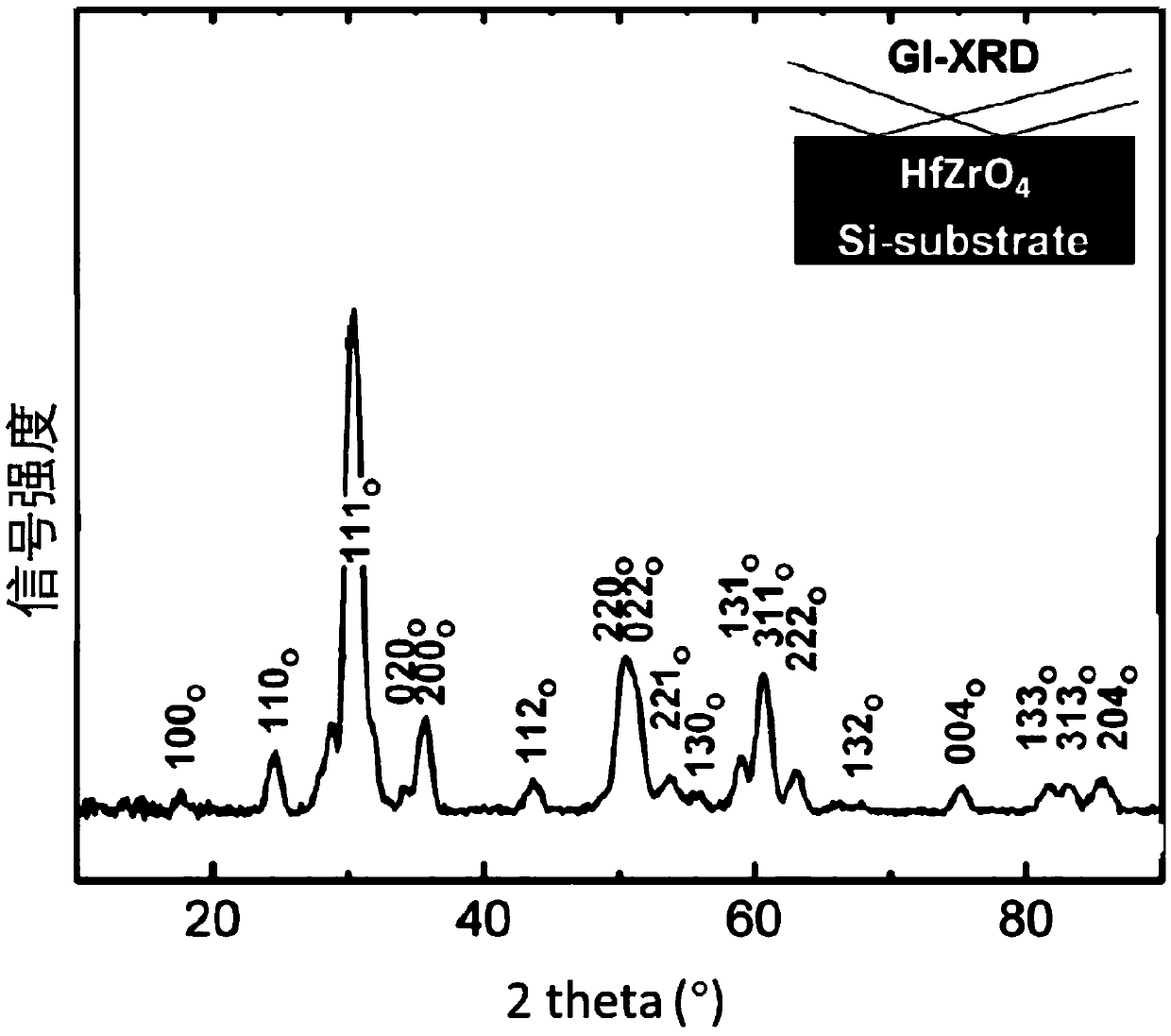

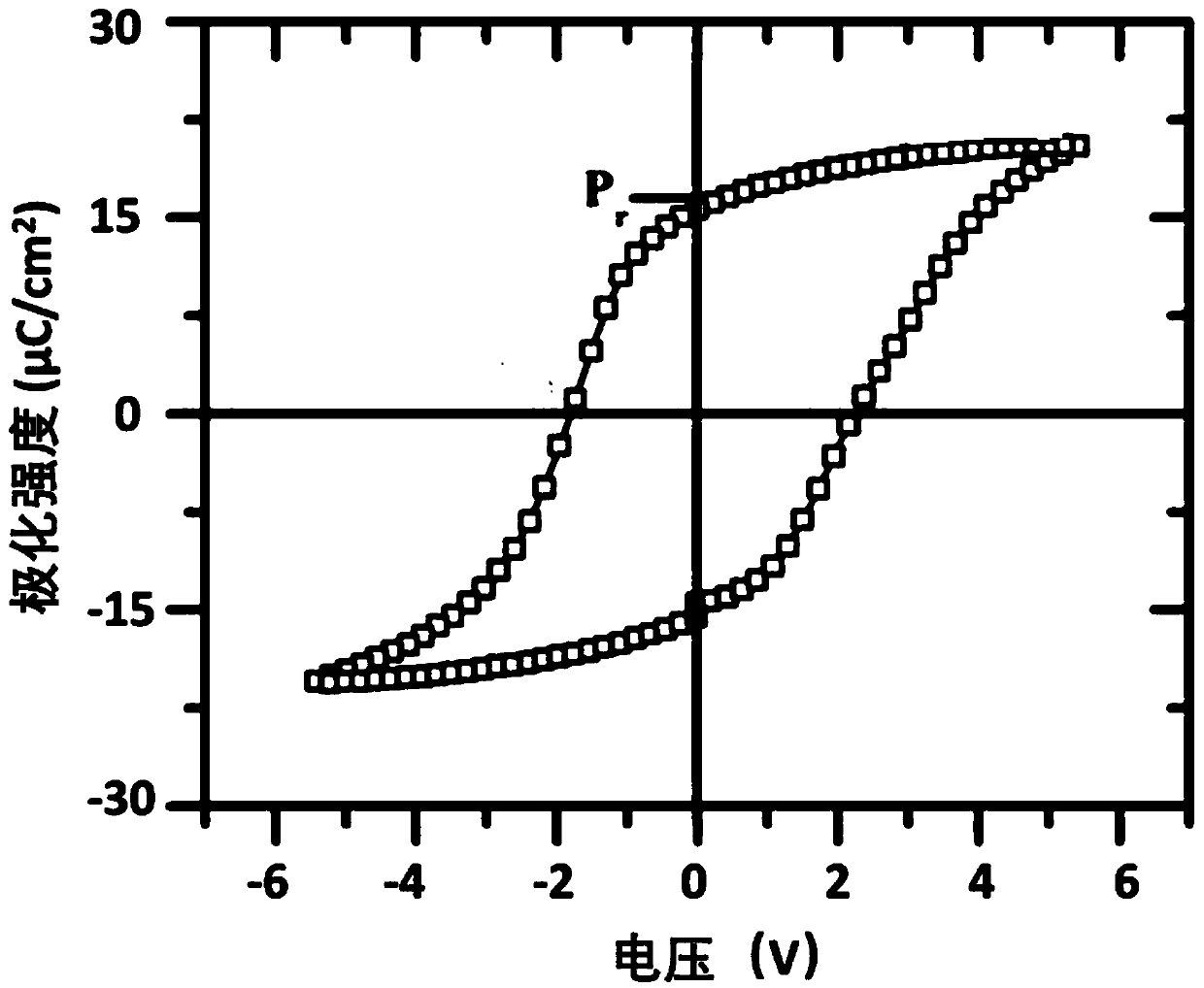

[0043] Thin Film Properties Test:

[0044] The obtained film was measured by ellipsometry, and the thickness of th...

Embodiment 2

[0046] A 12-inch silicon wafer is placed in a PEALD chamber and heated to 270°C. Introduce vaporized hafnium tetrachloride into the ALD chamber by means of vapor draw for 5 seconds. After drawing out the excess precursor, fill the ALD chamber with 250 sccm of oxygen and light the plasma (450W), the duration of the plasma is 5 seconds; after pumping out the by-products, introduce gasified zirconium tetrachloride into the ALD chamber through steam suction, and the import time is 3.5 seconds. The ALD chamber is filled with 250 sccm of oxygen, and the plasma (300W) is turned on, and the duration of the plasma is 5 seconds; one cycle of deposition is completed after the by-product is pumped out.

[0047] Repeat this film deposition for a total of 60 cycles. The film was annealed in a chamber at 600°C for 30 minutes.

[0048] Thin Film Properties Test:

[0049] The obtained film was measured by ellipsometry, and the thickness of the film was 55A; XPS element composition analysis ...

Embodiment 3

[0051] A 12-inch silicon wafer is placed in a PEALD chamber and heated to 350°C. Introduce vaporized tris(dimethylamino)-trimethylsilyl-cyclopentadienyl hafnium into the ALD chamber by vapor draw for 7 seconds, after drawing out the excess precursor , fill the ALD chamber with 300 sccm of ozone, and complete the deposition through a thermal reaction at 450 °C; after pumping out the by-products, introduce gasified tris(dimethylamino)-trimethyl Silicon-based-cyclopentadienyl zirconium, the import time is 10 seconds, after the excess precursor is pumped out, 300 sccm of ozone is filled into the ALD chamber, and the deposition is completed through a thermal reaction at 450 °C; the deposition is completed after the by-product is pumped out of a cycle.

[0052] Repeat this film deposition for a total of 60 cycles. The film was annealed in a chamber at 630°C for 30 minutes.

[0053] Thin Film Properties Test:

[0054] The obtained film was measured by ellipsometry, and the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com