Method for preparing ferritin-chitosan complex by utilizing transglutaminase and chitosan

A technology of transglutaminase and chitosan, which is applied in the direction of transferrin, chemical instruments and methods, animal/human protein, etc., can solve problems such as patent publications that have not been found, and achieve improved bioavailability and stability Sexuality, the effect of improving iron bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

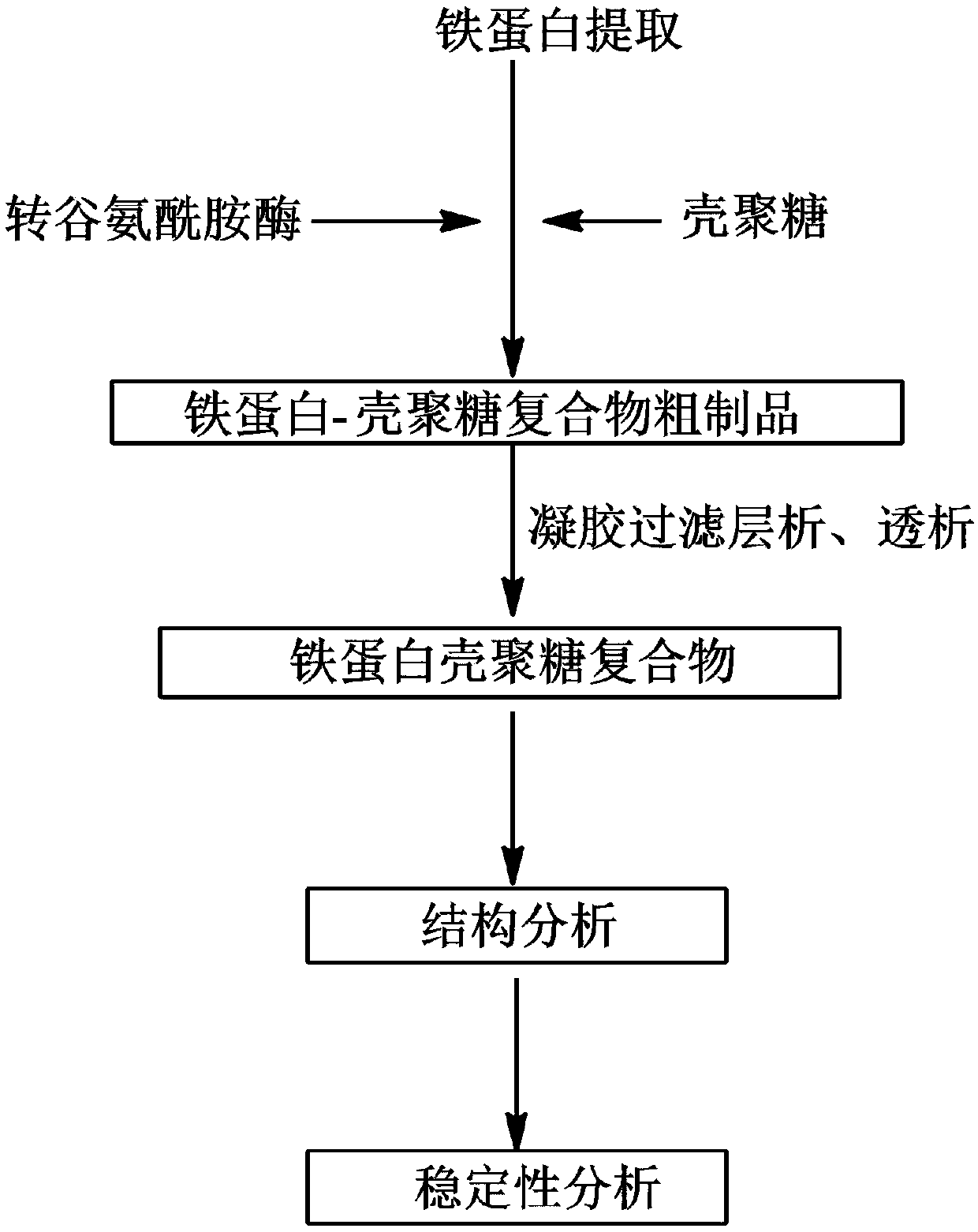

[0034] A method utilizing transglutaminase and chitosan to prepare ferritin-chitosan complex, the steps are as follows:

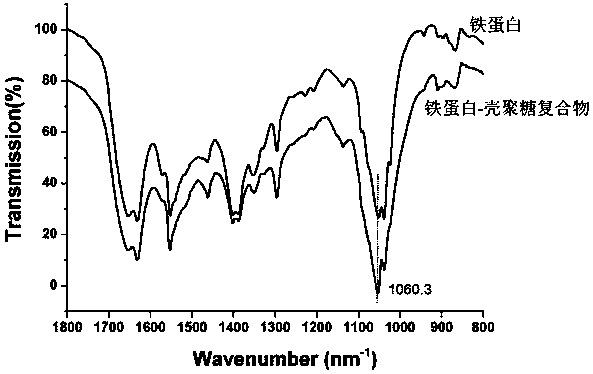

[0035] Using commercially available red beans as raw materials, ferritin is extracted and separated by water extraction, chitosan is covalently bound to ferritin by the catalysis of transglutaminase, and effective binding components are separated by gel filtration , the obtained ferritin-chitosan complex. The heat stability of the complex and the ability to resist gastrointestinal digestive enzymes are significantly enhanced.

[0036] Preferably, the specific steps are as follows:

[0037] (1) Use commercially available red beans as raw materials, soak in distilled water at 4°C overnight (about 10-12h), after peeling, add 2 times the volume of 50mM KH containing 1% PVP2 PO 4 -Na 2 HPO 4 (pH 7.0), and homogenized 3 times with an in-cut homogenizer, each time for 2-3 minutes, and filtered the bean dregs with a 200-mesh filter. Centrifuge the collected ho...

Embodiment 2

[0046] A method utilizing transglutaminase and chitosan to prepare ferritin-chitosan complex, the steps are as follows:

[0047] The method uses ferritin extracted from soybeans as a raw material, utilizes the catalysis of transglutaminase to bind chitosan to ferritin, and separates effective binding components through gel filtration to obtain ferritin-chitosan The obtained ferritin-chitosan complex has higher stability than ferritin.

[0048] Step by step, the specific steps are as follows:

[0049] ⑴Using red beans as raw materials, soak in distilled water at 4°C overnight (about 10-12h), after manual peeling, add 2 times the volume of 50mM KH containing 1% PVP 2 PO 4 -Na 2 HPO 4 (pH 7.0), and homogenized 3 times with an in-cut homogenizer, each time for 2-3 minutes, and filtered the bean dregs with a 200-mesh filter. Centrifuge the collected homogenate at 6000g at 4°C for 10-15 minutes, discard the precipitate, and obtain the crude protein supernatant;

[0050] (2) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com