Efficient enhanced flame-retardant functional master batch for direct injection molding of PC-ABS alloy and preparation method of functional master batch

A technology of injection molding and functional masterbatch, applied in the field of high-efficiency reinforced halogen-free flame retardant functional masterbatch and its preparation, can solve the mismatch of processing temperature, reduce the processing and preparation temperature of phosphorus/nitrogen-containing flame retardant masterbatch, etc. problem, to achieve the effect of improving modification efficiency, excellent reinforcement and flame retardant effect, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

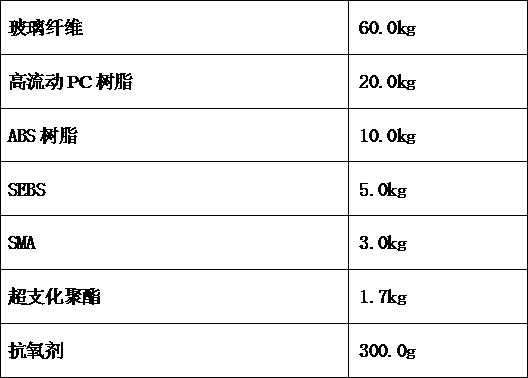

[0035] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for PC / ABS alloy direct injection molding, which is composed of two masterbatches A and B. The quality ratio of raw materials for the A masterbatch is as follows:

[0036]

[0037] The antioxidant is 4-[(4,6-Dioctylthio-1,3,5-triazin-2-yl)]-2,6-di-tert-butylphenol (trade name Antioxidant 565) and bis(2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) in a mass ratio of 1:1.

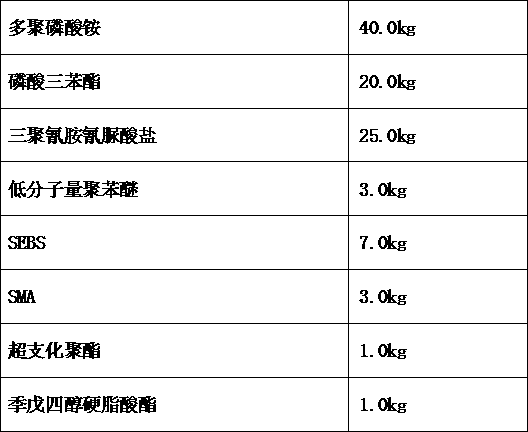

[0038] The mass ratio of the raw materials of the B masterbatch is as follows:

[0039]

[0040] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mass ratio requirements, put high-flow PC resin, ABS resin, SEBS, SMA, hyperbranched polyester and antioxidant into a high-speed mixer and mix evenly, and then The obtained mixture and the weighed chopped glass fibers are respectively fed into a twin-screw extruder through a conical feeder a...

Embodiment 2

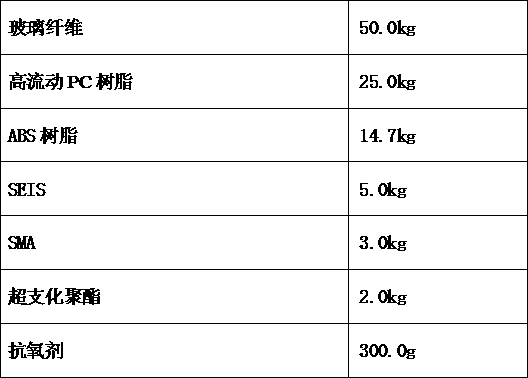

[0043] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for PC / ABS alloy direct injection molding, which is composed of two masterbatches A and B. The quality ratio of raw materials for the A masterbatch is as follows:

[0044]

[0045] The antioxidant is 4-[(4,6-Dioctylthio-1,3,5-triazin-2-yl)]-2,6-di-tert-butylphenol (trade name Antioxidant 565) and bis(2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) in a mass ratio of 1:1.

[0046] The mass ratio of the raw materials of the B masterbatch is as follows:

[0047]

[0048] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mass ratio requirements, put high-flow PC resin, ABS resin, SEIS, SMA, hyperbranched polyester and antioxidant into a high-speed mixer and mix evenly, and then The obtained mixture and the weighed chopped glass fibers are respectively fed into a twin-screw extruder through a conical feeder a...

Embodiment 3

[0051] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for PC / ABS alloy direct injection molding, which is composed of two masterbatches A and B. The quality ratio of raw materials for the A masterbatch is as follows:

[0052]

[0053] The antioxidant is 4-[(4,6-Dioctylthio-1,3,5-triazin-2-yl)]-2,6-di-tert-butylphenol (trade name Antioxidant 565) and bis(2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) in a mass ratio of 1:1.

[0054] The mass ratio of the raw materials of the B masterbatch is as follows:

[0055]

[0056] The preparation method of A masterbatch is as follows: Weigh all raw materials according to the above mass ratio requirements, put high-flow PC resin, ABS resin, SBS, SMA, hyperbranched polyester and antioxidant into a high-speed mixer and mix evenly, and then The obtained mixture and the weighed chopped glass fibers are respectively fed into a twin-screw extruder through a conical feeder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com