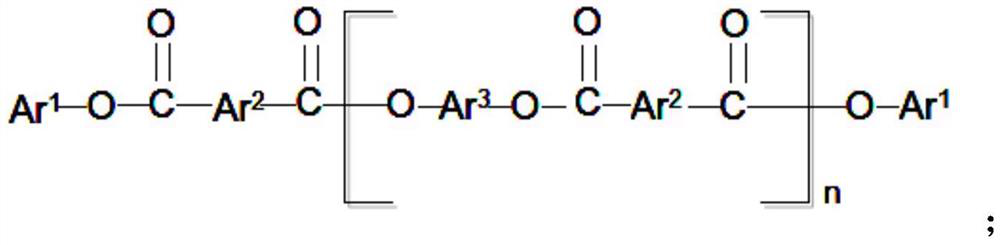

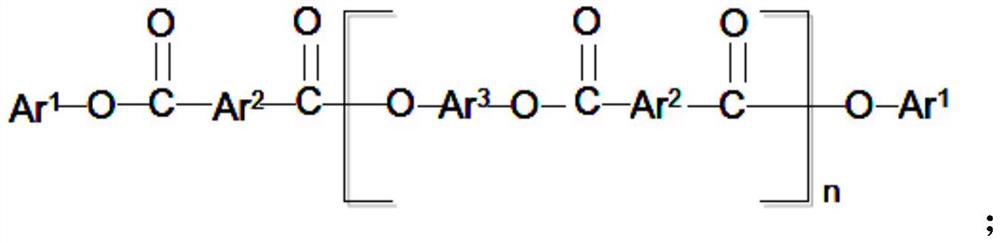

A fluorine-containing active ester, its preparation method, and its cured resin

A resin cured product and active ester technology, applied in the field of polymer materials, can solve the problems of high dielectric constant and dielectric loss angle, and cannot adapt to the high frequency of signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method according to above-mentioned fluorine-containing active ester, comprises the following steps:

[0042] (a) mixing the fluorine-containing aromatic dihydric phenol and the organic solvent according to the formula amount, feeding nitrogen gas, dissolving, and obtaining the fluorine-containing aromatic dihydric phenol solution;

[0043] (b) making a solution of the basic catalyst; adding an esterification reagent to the fluorine-containing aromatic dihydric phenol solution according to the formula quantity and dissolving it, adding the basic catalyst solution according to the formula quantity, stirring and reacting for 1 hour, and obtaining a reaction solution A;

[0044] (c) adding an end-capping agent to the reaction solution A according to the formula and reacting for 1h to 3h to obtain the reaction solution B;

[0045] (d) The reaction solution B is washed with water, neutralized, and dehydrated to obtain a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com