Cyclone system for sludge drying

A technology of sludge drying and cyclone, which is applied in the field of cyclone system, can solve the problems of incomplete separation of solids and liquids, uneven mixing of materials and cyclones, and the existence of dead angles, etc., and achieve compact structure, reduce dust at the outlet, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

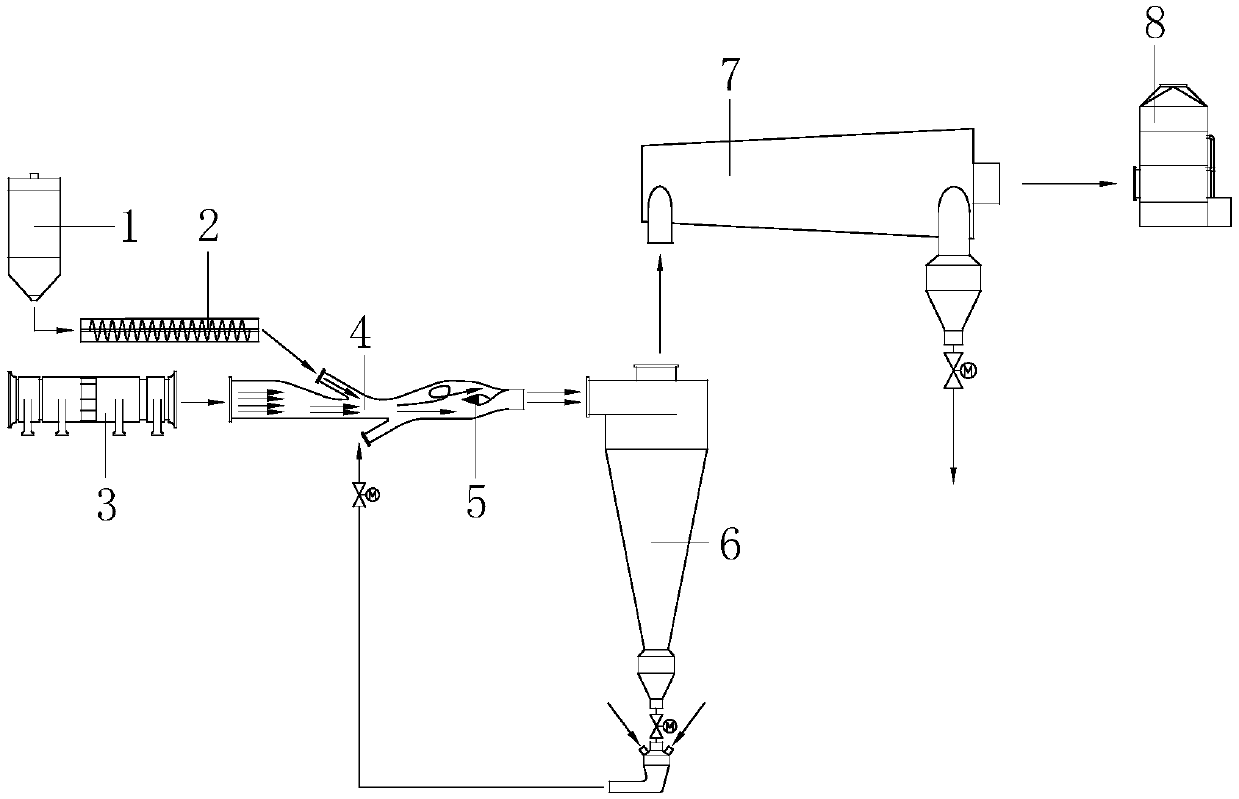

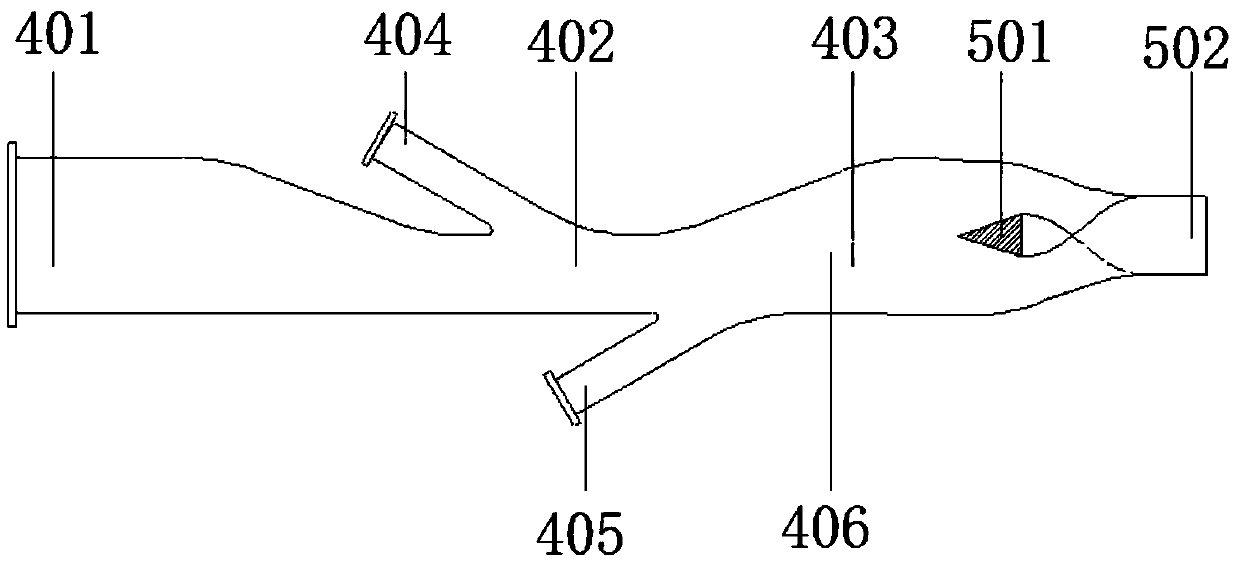

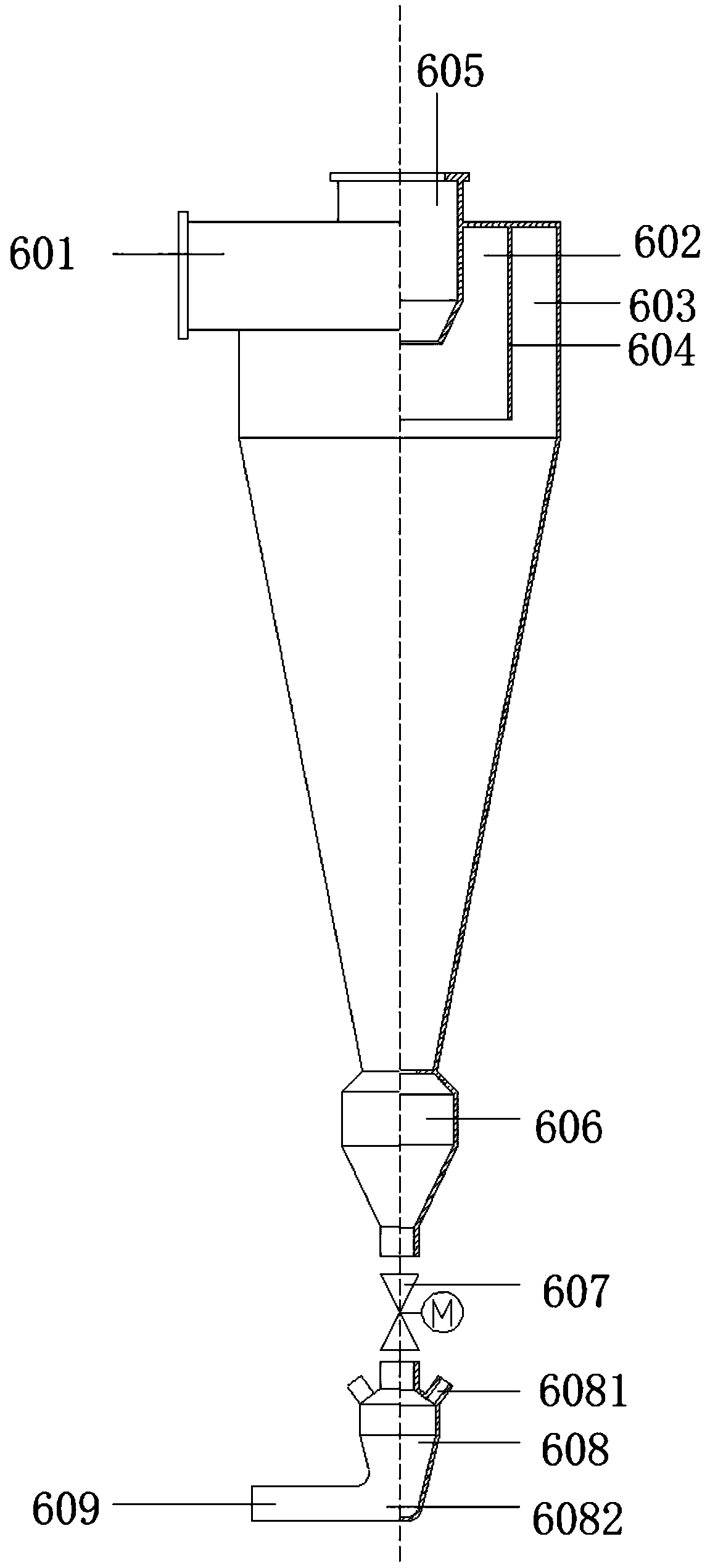

[0026] refer to figure 1 , image 3 and Figure 4 , a cyclone system for sludge drying in the present invention, including a silo 1 for holding and discharging materials, a screw conveying pipe 2 for conveying materials, a high-speed cyclone 3 for inputting airflow, and a The eccentric Venturi tube 4 that mixes the material into the airflow, the wedge-shaped twisted tube splitter 5, the semi-double air duct cyclone separator 6, the devious centrifugal deceleration settler 7 and the spray tower 8; The eccentric Venturi tube 4 is connected, and the two ends of the high-speed cyclone 3 are respectively connected with the air compressor and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com