Preparation method of high-stability water-based nano magnetic fluid

A nano-magnetic, high-stability technology, applied in the field of materials, can solve the problems of high equipment requirements, unfavorable mass production, and wide particle size distribution, and achieve high saturation magnetization, good biocompatibility, and excellent stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

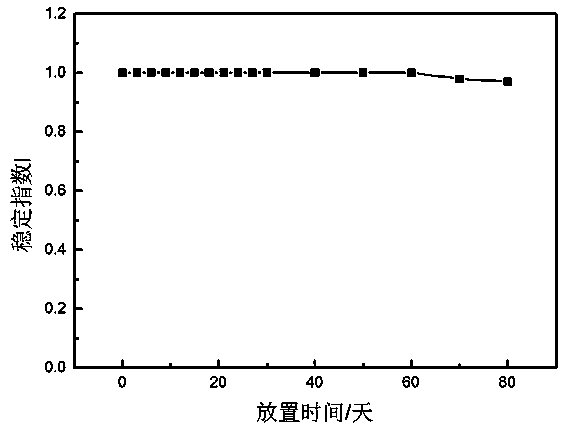

Embodiment 1

[0030] Add deionized water to a 250 mL three-neck flask under nitrogen protection, and heat up to 60 °C; then dissolve 2.35 g FeCl in dilute hydrochloric acid 3 ·6H 2 O, 1.2 g FeSO 4 ·7H 2 O was added to the above-mentioned three-necked flask, and stirred slowly for 5 min; under vigorous stirring, 50 mL of ammonia solution (concentration: 23 wt%) was quickly added to the iron salt solution, and the solution quickly turned black, and 1 g of ferric oxide nanoparticles were obtained. ; Subsequently, dextran was added 10 times in 20 min, 0.1 g each time, to modify the surface of the ferric oxide nanoparticles generated, the reaction temperature was raised to 70 °C, and the reaction was continued for 60 min; the heating was turned off, Cool the black suspension to room temperature, wash the prepared iron ferric oxide nanoparticles with deionized water, and perform magnetic separation, repeat several times until the solution is neutral and the conductivity is small, and the unreac...

Embodiment 2

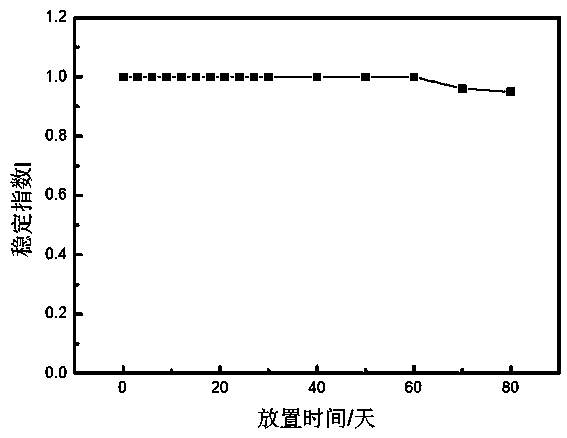

[0032] Add deionized water to a 250 mL three-neck flask under nitrogen protection, and heat up to 50 °C; then dissolve 2.35 g FeCl in dilute hydrochloric acid 3 ·6H 2 O, 1.2 g FeSO 4 ·7H 2O was added to the above-mentioned three-necked flask, and stirred slowly for 5 min; under vigorous stirring, 45 mL of ammonia solution (24 wt%) was quickly added to the iron salt solution, and the solution quickly turned black to obtain 1 g of ferric oxide nanoparticles ; Subsequently, dextran was added 10 times in 20 min, adding 0.1 g each time, to modify the surface of the generated Fe3O4 nanoparticles, and the reaction temperature was increased to 70 °C, and the reaction was continued for 90 min; the heating was turned off, Cool the black suspension to room temperature, wash the prepared iron ferric oxide nanoparticles with deionized water, and perform magnetic separation, repeat several times until the solution is neutral and the conductivity is small, and the unreacted Fe 2+ , Fe 3+...

Embodiment 3

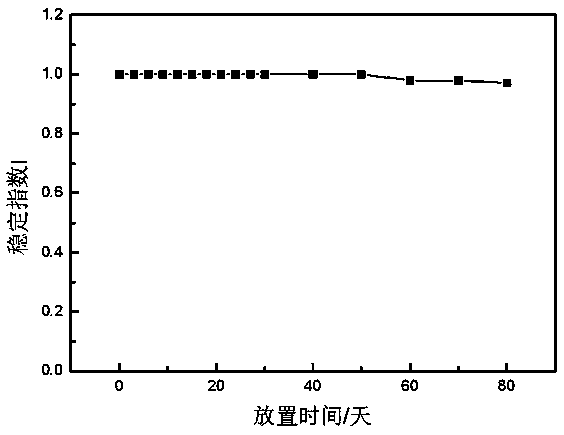

[0034] Add deionized water to a 250 mL three-neck flask under nitrogen protection, and heat up to 60 °C; then dissolve 2.35 g FeCl in dilute hydrochloric acid 3 ·6H 2 O, 1.2 g FeSO 4 ·7H 2 O was added to the above-mentioned three-necked bottle, and stirred slowly for 5 min; under vigorous stirring, 45 mL of ammonia solution (mass concentration: 24wt%) was quickly added to the iron salt solution, and the solution quickly turned black to obtain 1 g of ferric oxide Nanoparticles; then, dextran was added 10 times in 20 min, 0.14 g each time, to modify the surface of the ferric oxide nanoparticles, and the reaction temperature was raised to 70 ℃, and the reaction was continued for 60 min; close Heating, cooling the black suspension to room temperature, washing the prepared iron ferric oxide nanoparticles with deionized water, and performing magnetic separation, repeating several times until the solution is neutral and the conductivity is small, to remove unreacted Fe 2+ , Fe 3+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com