Super-light resistive random access memory and preparation method thereof

A technology of resistive variable memory and silk protein, which is applied in the field of electronic technology and memory devices, can solve the problems of heavy resistance variable memory and lack of memory technology, and achieve the effects of no biological toxicity, less pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

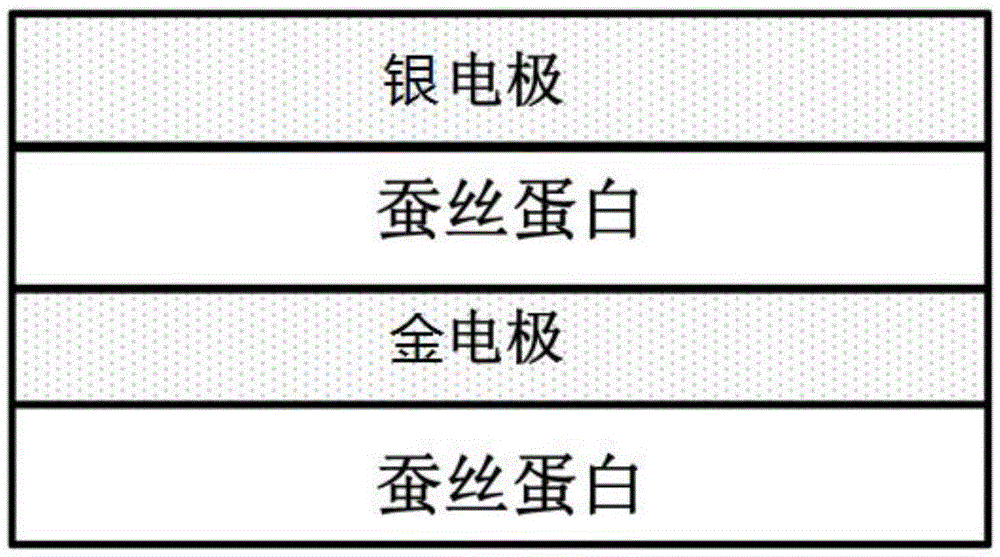

[0028] A method for preparing an ultra-light resistive variable memory, comprising the following steps:

[0029] Step 1, growing a single-layer perfluorododecyltrichlorosilane film on a silicon substrate by chemical vapor phase method;

[0030] Step 2, growing a gold thin film electrode layer on the perfluorododecyltrichlorosilane layer, the thickness of the grown gold thin film electrode layer is 20-50 nanometers;

[0031] Step 3: On the electrode layer of the gold film, drop-coat the silk protein film. When drip-coating the silk protein film, use an aqueous solution of silk protein with a mass concentration of 1%-6%. After the drop-coating, place it in the atmosphere for 24 hours to dry naturally , the thickness of the formed silk protein film is 1-10 microns;

[0032] Step 4, peel off the silk protein film from the substrate substrate, during this process, the gold film electrode will be adhered to the silk protein film and be peeled off together, and the peeled silk prote...

Embodiment 1

[0036] Step 1, growing a single-layer perfluorododecyltrichlorosilane film on a silicon substrate by chemical vapor phase method;

[0037] Step 2, growing a gold thin film electrode layer on the perfluorododecyltrichlorosilane layer, the thickness of the grown gold thin film electrode layer is 50 nanometers;

[0038] Step 3: On the electrode layer of the gold film, drop-coat the silk protein film. When drip-coating the silk protein film, use an aqueous solution of silk protein with a mass concentration of 1%-6%. After the drop-coating, place it in the atmosphere for 24 hours to dry naturally , the thickness of the formed fibroin film is 10 microns;

[0039] Step 4, peel off the silk protein film from the substrate substrate, during this process, the gold film electrode will be adhered to the silk protein film and be peeled off together, and the peeled silk protein film will be adhered to the supporting substrate, where the gold The surface of the thin film electrode is upward...

Embodiment 2

[0044] Step 1, growing a single-layer perfluorododecyltrichlorosilane film on a silicon substrate by chemical vapor phase method;

[0045] Step 2, growing a gold thin film electrode layer on the perfluorododecyltrichlorosilane layer, the thickness of the grown gold thin film electrode layer is 20 nanometers;

[0046] Step 3, drip-coat silk protein film on the gold film electrode layer. When drip-coating the silk protein film, use an aqueous solution of silk protein with a mass concentration of 1%. After drip-coating, place it in the atmosphere for 24 hours to dry naturally, and the formed The thickness of the silk protein film is 1 micron;

[0047] Step 4, peel off the silk protein film from the substrate substrate, during this process, the gold film electrode will be adhered to the silk protein film and be peeled off together, and the peeled silk protein film will be adhered to the supporting substrate, where the gold The surface of the thin film electrode is upward;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com