Automobile transmission straight spur gear end face chamfering machining device

A technology of spur gears and automobile transmissions, which is applied in the field of gear processing, can solve the problems of high labor intensity, accelerated gear wear, and labor-intensive problems, and achieve the effects of improving processing quality, processing accuracy, and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

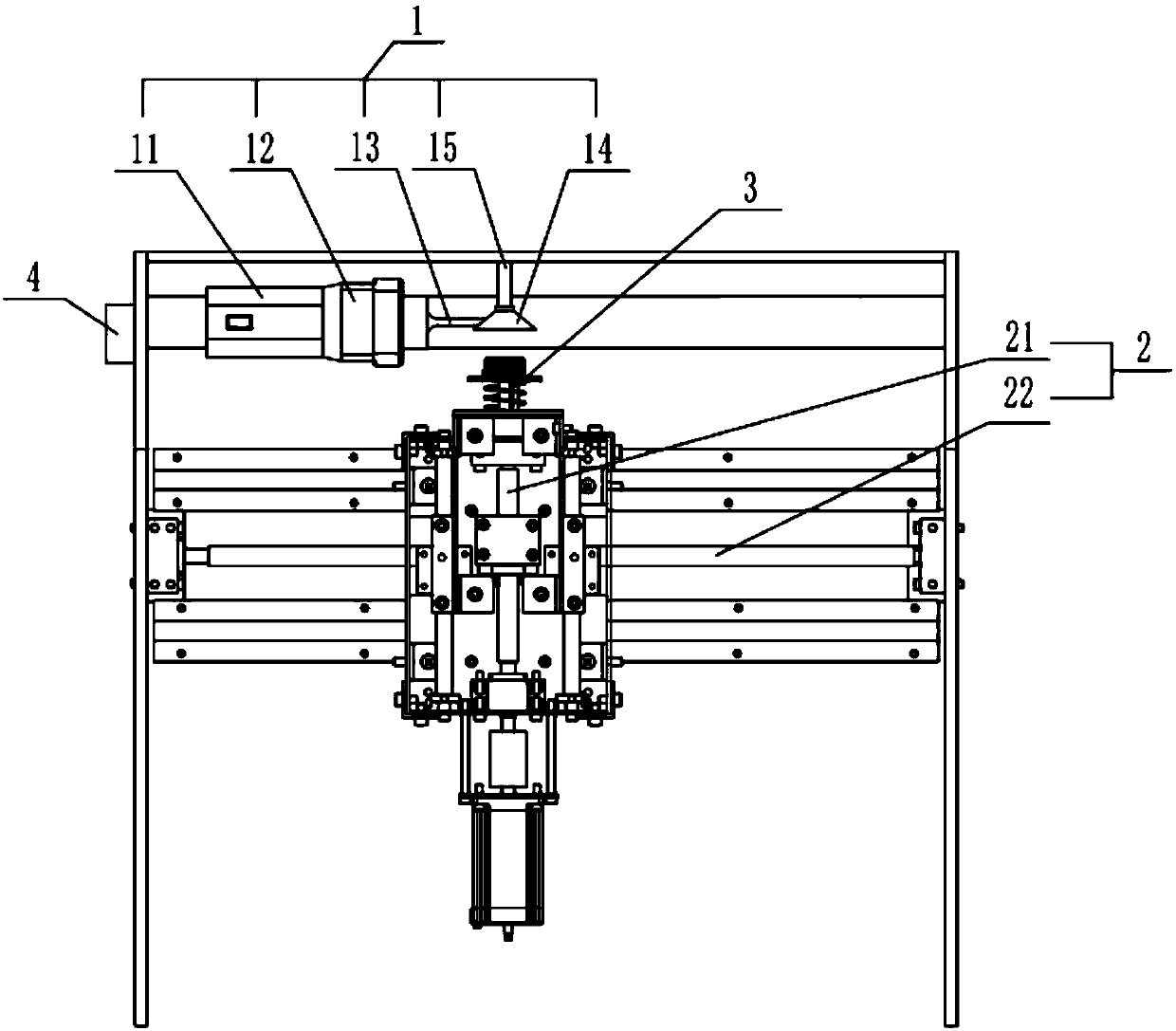

[0040] According to one embodiment of the present invention, the ultrasonic vibration system includes an ultrasonic generator 11, an ultrasonic transducer 12, and a horn 13, the ultrasonic transducer 12 is electrically connected to the ultrasonic generator 11, and the ultrasonic transducer 12 The rod 13 is arranged laterally and the two ends of the horn 13 are respectively connected to the ultrasonic transducer 12 and the tool head 14, the axis of the horn 13 is perpendicular to the axis of the tool head 14, The horn 13 is connected to the outer circumference of the tool head 14 and is tangent to the outer circumference of the tool head 14 .

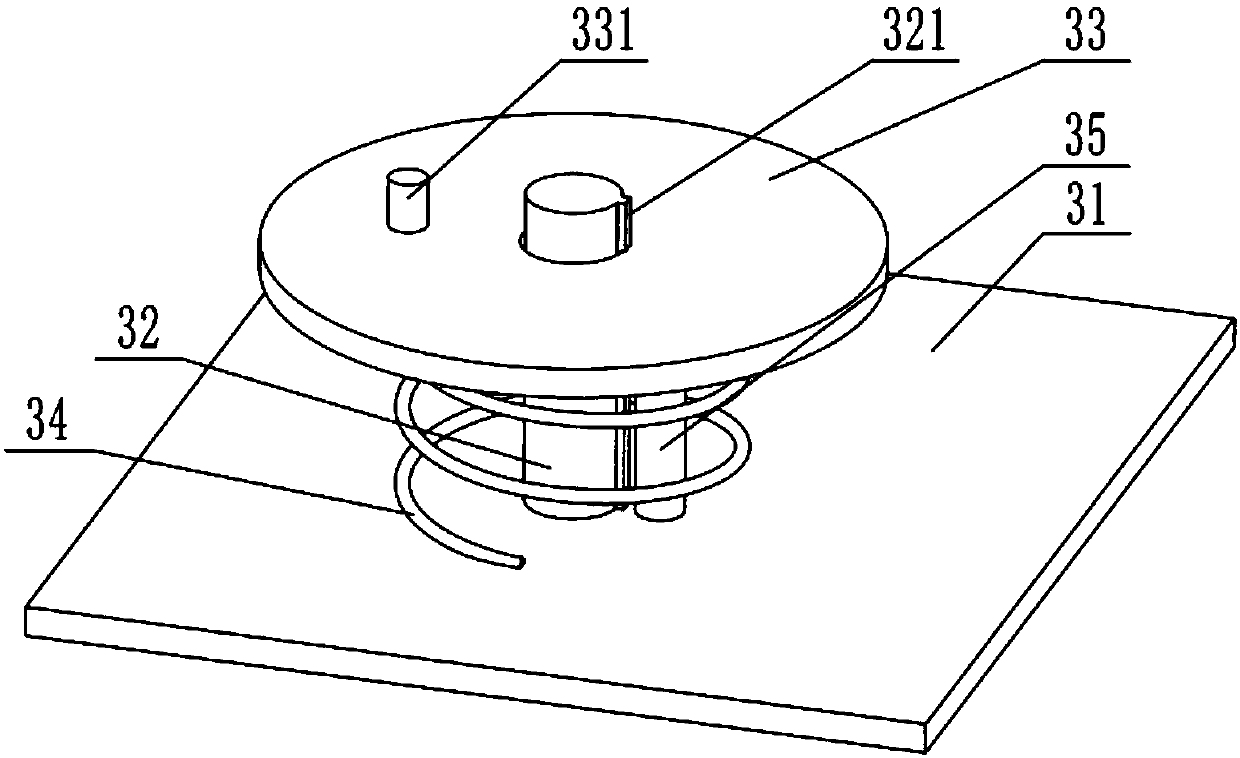

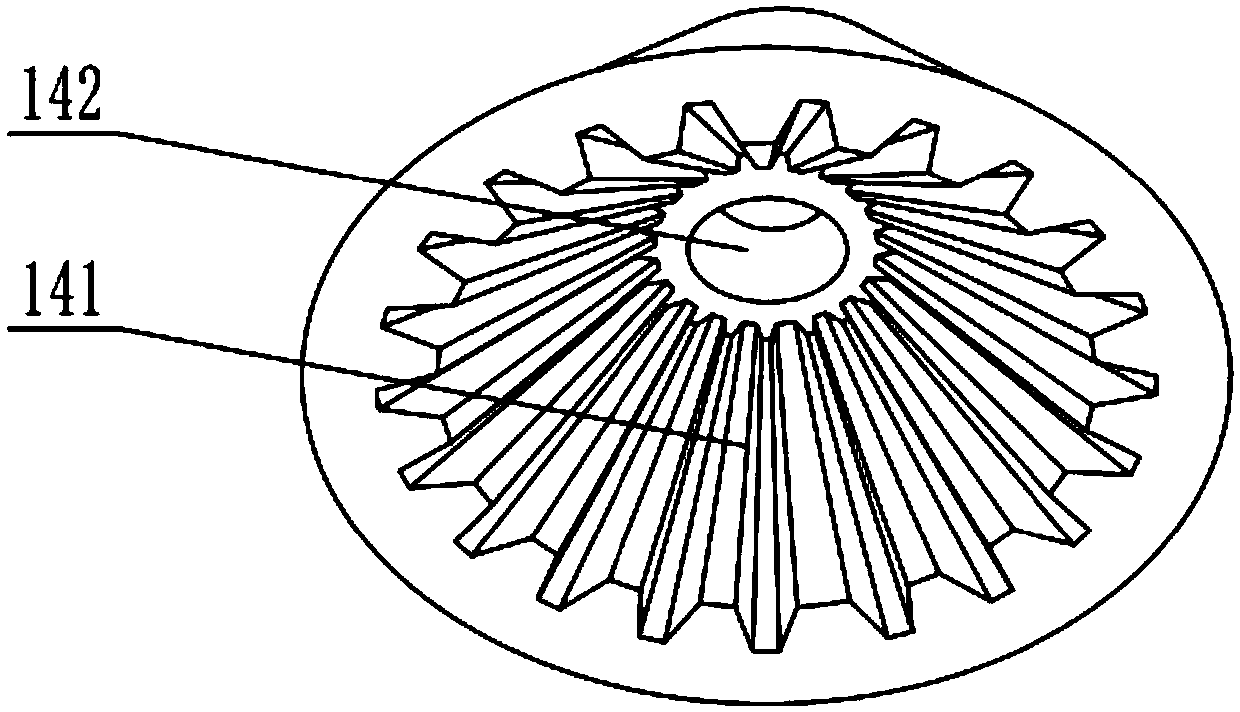

[0041] In order to efficiently deburr the tool head 14, according to an embodiment of the present invention, the cavity 141 includes an inner surface 1411 and an inner bottom surface, and any straight line on the inner surface 1411 is aligned with the axis of the gear guide post 32 The included angle is between 50° and 70°.

[0042] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com