Withdrawal and straightening machine for square and round billets

The technology of a tension leveler and a square circle is applied in the field of both a square and a circle billet and a tension leveler, which can solve the problems of increasing workload, reducing production efficiency, increasing time cost, etc., and achieving the effect of reducing replacement time, improving work efficiency, and replacing quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

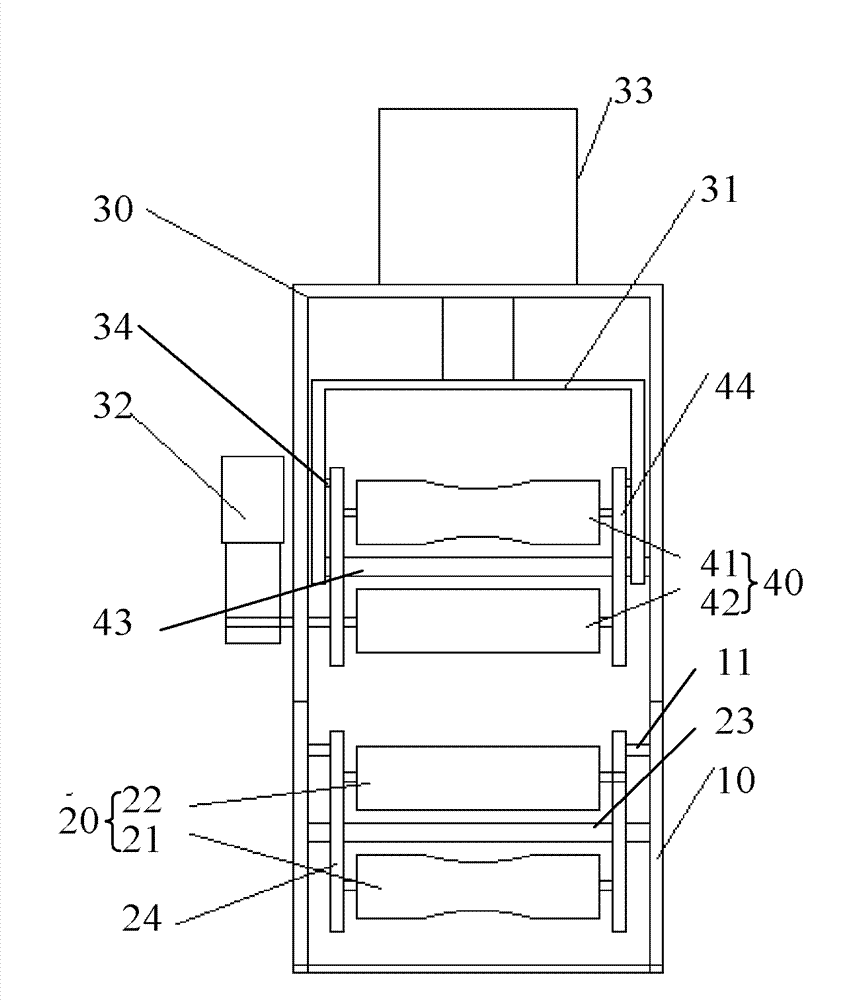

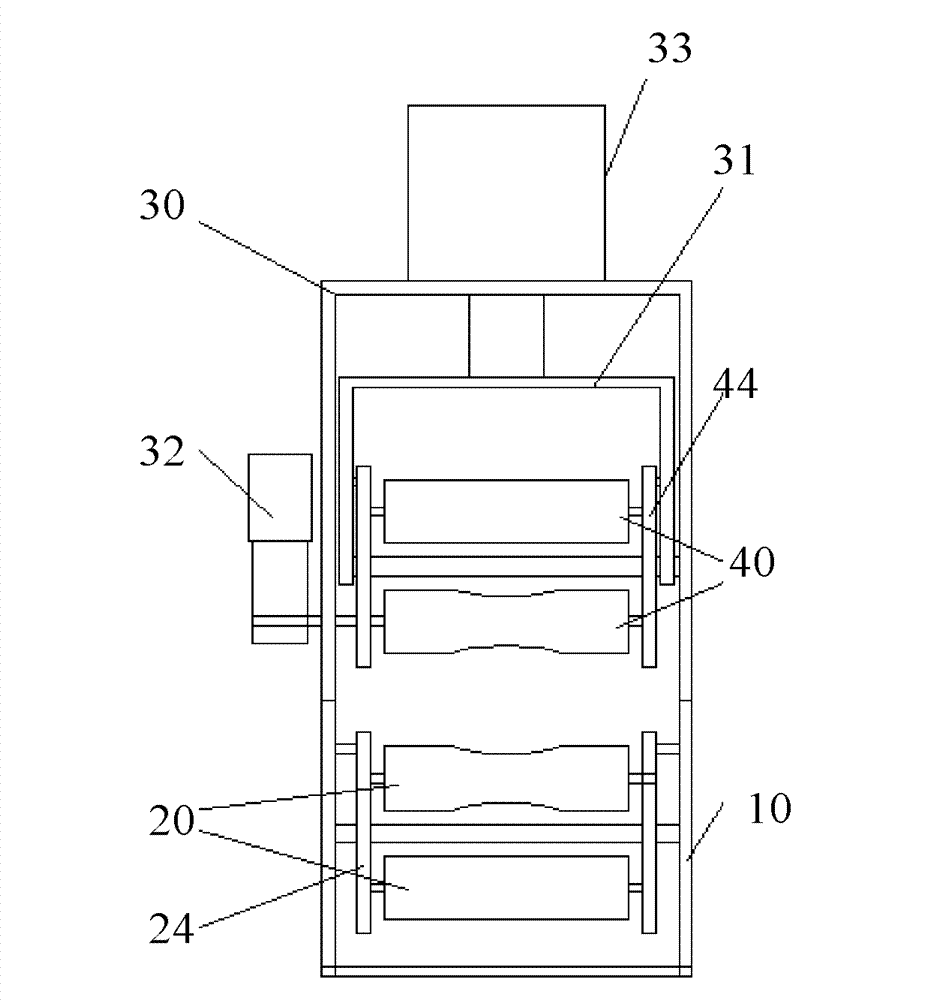

[0020] Such as figure 1 and figure 2 As shown, according to the embodiment of the present invention, the square and round billet double-purpose tension leveling machine includes a lower base 10 supporting the entire tension leveler, and an upper fixing plate 30 is fixedly arranged on the lower base 10, and the upper fixing plate 30 can be welded on the lower base 10, It can also be fixedly connected to the lower base 10 by bolts. The lower base 10 is two oppositely arranged triangular support plates, a first rotating shaft 23 is arranged in the middle of the triangular support plate, and a lower roller mechanism 20 is arranged on the rotating shaft 23, and the lower roller mechanism 20 is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com