Device for detecting and analyzing steelmaking high-temperature liquid-state furnace slag components on line

An analysis device and slag technology, which is applied in the field of on-line detection and analysis devices for steelmaking high-temperature liquid slag components, can solve the problems of difficult formation of aggregation points, shortened analysis time, and long time required to ensure reproducibility and optical transmission performance Good, good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

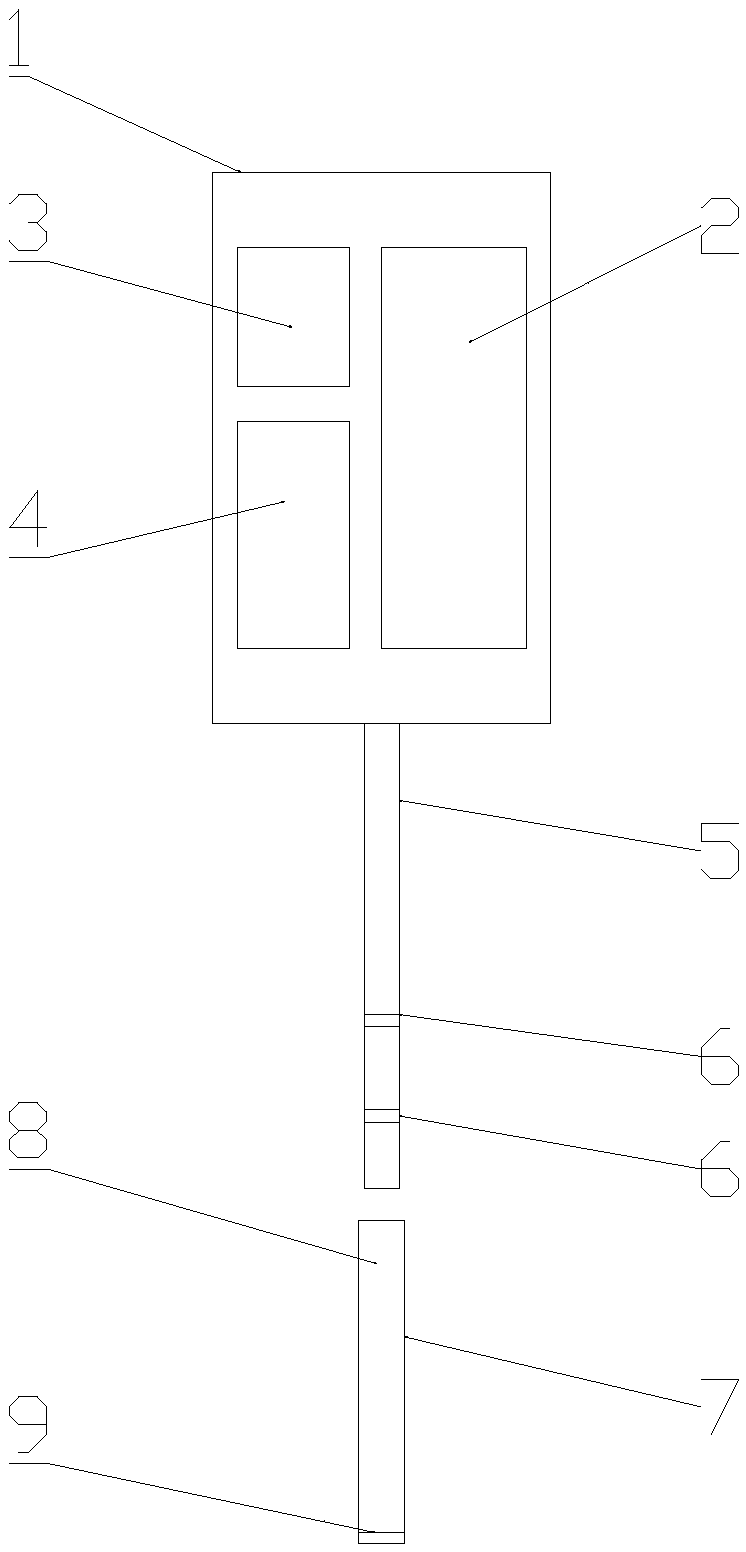

[0022] see figure 1 , an on-line detection and analysis device for steelmaking high-temperature liquid slag composition, comprising a rapid slag composition analyzer 1 and an optical probe 7, the fast slag composition analyzer 1 and the optical probe 7 are connected and separated by plugging; the The slag composition rapid analyzer 1 includes a laser 2, a controller 3, a spectrometer 4 and a probe conduit 5, and the laser 2, the controller 3, the spectrometer 4 and the probe conduit 5 are connected by electrical signal transmission , used to analyze the slag composition and output the results; the optical probe 7 includes a hollow tube 8 and a glass window 9, the glass window 9 is fixed on one end of the hollow tube 8, and the other end of the hollow tube 8 One end is open.

[0023] As a further solution of the present invention, the power range of the laser 2 is 20-400mj.

[0024] As a further solution of the present invention, the probe conduit 5 is a hollow metal circular...

Embodiment 2

[0027] see figure 1 , an on-line detection and analysis device for steelmaking high-temperature liquid slag composition, comprising a rapid slag composition analyzer 1 and an optical probe 7, the fast slag composition analyzer 1 and the optical probe 7 are connected and separated by plugging; the The slag composition rapid analyzer 1 includes a laser 2, a controller 3, a spectrometer 4 and a probe conduit 5, and the laser 2, the controller 3, the spectrometer 4 and the probe conduit 5 are connected by electrical signal transmission , used to analyze the slag composition and output the results; the optical probe 7 includes a hollow tube 8 and a glass window 9, the glass window 9 is fixed on one end of the hollow tube 8, and the other end of the hollow tube 8 One end is open.

[0028] As a further solution of the present invention, the inner diameter of the hollow tube 8 is 20-120 mm, the length is 300-1200 mm, the material is light refractory material, and the tube wall thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com