Method for synthesizing propionate through ester-ester exchange path

A technology of propionate and transesterification, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. Harsh and other problems, to achieve the effect of multiple times of repeated use, short reaction time, and short reaction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation methods of several typical catalysts are as follows:

[0029] The imidazole ionic liquid is 1-methyl-3-methylimidazolium bromide, and its preparation method is as follows: use N-methylimidazole and methyl bromide as raw materials to prepare the ionic liquid, and first pour the measured N-methylimidazole into In a 250 mL three-necked flask, heat it in a water bath at 30 °C, then add a metered amount of methyl bromide dropwise to the above solution under stirring, and fill it with N 2 protection, and continued to stir for 12 h to obtain white crystals, which were washed 3 times with 100 mL of ethyl acetate to remove unreacted raw materials. components, and finally vacuum-dried at 70 °C for 24 h to obtain 1-methyl-3-methylimidazolium bromide ionic liquid.

[0030]N-ethylpyridine tetrafluoroborate is selected as the pyridine ionic liquid, and its preparation method is as follows: Measure a certain amount of pyridine 79.1g and bromoethane 174.4g, respectivel...

Embodiment 1

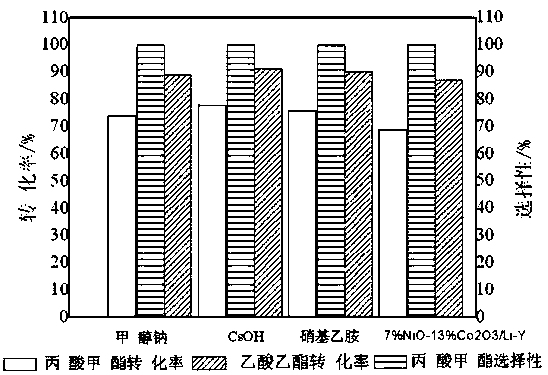

[0043] In a three-necked flask, the influence of different catalysts on the conversion of raw materials was explored. Methyl propionate and methyl acetate were added into a 250 mL three-neck flask, and catalysts such as ionic liquid, soluble strong base, organic base, and solid base were added respectively. The catalyst addition is 3% of the total mass of raw materials. The three-necked flask is connected with a spherical condenser and a thermometer. The reaction temperature is 84°C, the molar ratio of methyl propionate to ethyl acetate is 1:1, and the reaction time is 4 hours. Start stirring, heat the solution to a certain temperature for reaction, take a sample for analysis after 5 minutes of stabilization, inject gas chromatography, the chromatographic analysis conditions are: the temperature of the vaporization chamber is 230 °C, the FID detector is used, the detector temperature is 250 °C, and the chromatographic column is HP-FFAP , the stationary phase is modified poly...

Embodiment 2

[0048] In a three-necked flask, the influence of different reaction raw materials on the conversion rate of raw materials was explored. The catalyst is 7%NiO-13%Co2O3 / Li-Y as an example, and different esters of raw materials are added to a 250 mL three-necked flask, and the amount of 7%NiO-13%Co2O3 / Li-Y is 3% of the total mass of raw materials . The three-necked flask is connected with a spherical condenser and a thermometer. The reaction temperature is 84°C, the molar ratio of raw materials is 1:1, and the reaction time is 4 hours. Stirring was started, the solution was heated to react, and after being stable for 5 minutes, samples of different reaction raw materials were respectively taken for chromatographic analysis and calculation. The raw material conversion rate is shown in Table 2.

[0049] Table 2 Effect of different reaction raw materials on the conversion rate of raw materials

[0050]

[0051] As can be seen from Table 2, when the reaction raw material is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com