High-compaction spherical lithium iron phosphate, preparation method and lithium ion battery containing high-compaction spherical lithium iron phosphate

A lithium iron phosphate, high-pressure compaction technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of poor carbon film integrity, easy to fall off, low compaction density, low solid content, etc., and achieve improvement Compacted density, improved compacted density, good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

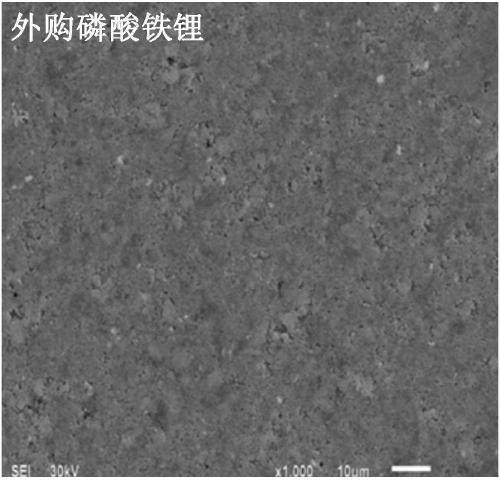

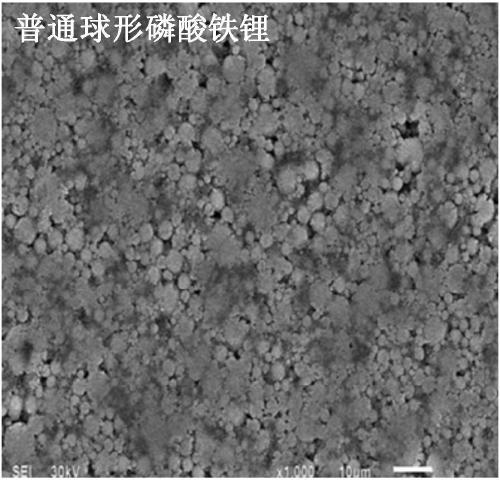

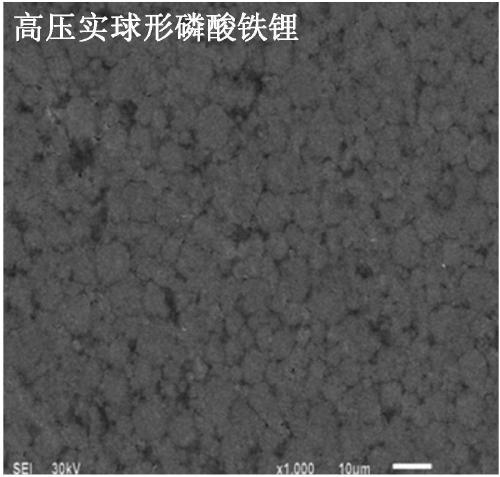

Image

Examples

Embodiment 1

[0050] A method for preparing a high-compact spherical lithium iron phosphate positive electrode material, comprising the following steps:

[0051] (1) Weigh iron phosphate, ammonium phosphate and lithium carbonate according to the molar ratio of Fe:P:Li=1:1.04:1.02, dissolve them in deionized water to form a mixed solution, and in the mixed solution, iron phosphate, ammonium phosphate and carbonic acid The concentrations of lithium were 1.536mol / L, 0.062mol / L, and 1.567mol / L;

[0052] (2) Glucose was dissolved in the obtained mixed solution according to 7.5% of the total salt mass, and sand-milled for 3 hours to obtain a precursor slurry with a particle size of D50=0.5 μm and D90=1.2 μm;

[0053] (3) The precursor slurry obtained in step (2) is dried and granulated in a pressure spray drying tower, and the granulation particle size is controlled to D50=5 μm, D90=10 μm, under the protection of argon, the temperature rise of 1 ° C / min The rate of heating is increased to 700°C ...

Embodiment 2

[0055] A method for preparing a high-compact spherical lithium iron phosphate positive electrode material, comprising the following steps:

[0056] (1) Weigh ferric sulfate, ammonium dihydrogen phosphate and lithium carbonate according to the molar ratio of Fe:P:Li=1:1.05:1.02, dissolve them in deionized water to form a mixed solution, and in the mixed solution, iron sulfate, diphosphate The concentrations of ammonium hydrogen and lithium carbonate are 0.682mol / L, 0.716mol / L, and 0.695mol / L, respectively;

[0057] (2) Dissolve polyethylene glycol in the mixed solution obtained above by 4.5% of the total salt mass, and carry out sand grinding for 2 hours to obtain a precursor slurry with a particle size of D50=0.6 μm and D90=1.5 μm;

[0058] (3) The precursor slurry obtained in step (2) is dried and granulated in a pressure spray drying tower, and the granulation particle size is controlled to D50=4 μm, D90=15 μm, under the protection of argon, the temperature rise of 1 ° C / min...

Embodiment 3

[0060] A method for preparing a high-compact spherical lithium iron phosphate positive electrode material, comprising the following steps:

[0061] (1) Weigh ferric nitrate, diammonium hydrogen phosphate and lithium carbonate according to the molar ratio of Fe:P:Li=1:1.03:1.02, dissolve them in deionized water to form a mixed solution, and in the mixed solution, ferric nitrate, hydrogen phosphate The concentrations of diammonium and lithium carbonate were 2.245mol / L, 2.313mol / L, and 2.29mol / L, respectively;

[0062] (2) Dissolve sucrose in the mixed solution obtained above by 5% of the total salt mass, and carry out sand grinding for 1 hour to obtain a precursor slurry with a particle size of D50=0.8 μm and D90=1.6 μm;

[0063] (3) The precursor slurry obtained in step (2) is dried and granulated in a pressure spray drying tower, and the granulation particle size is controlled to D50=7 μm, D90=18 μm, under the protection of argon, the temperature rise of 1°C / min The rate of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com