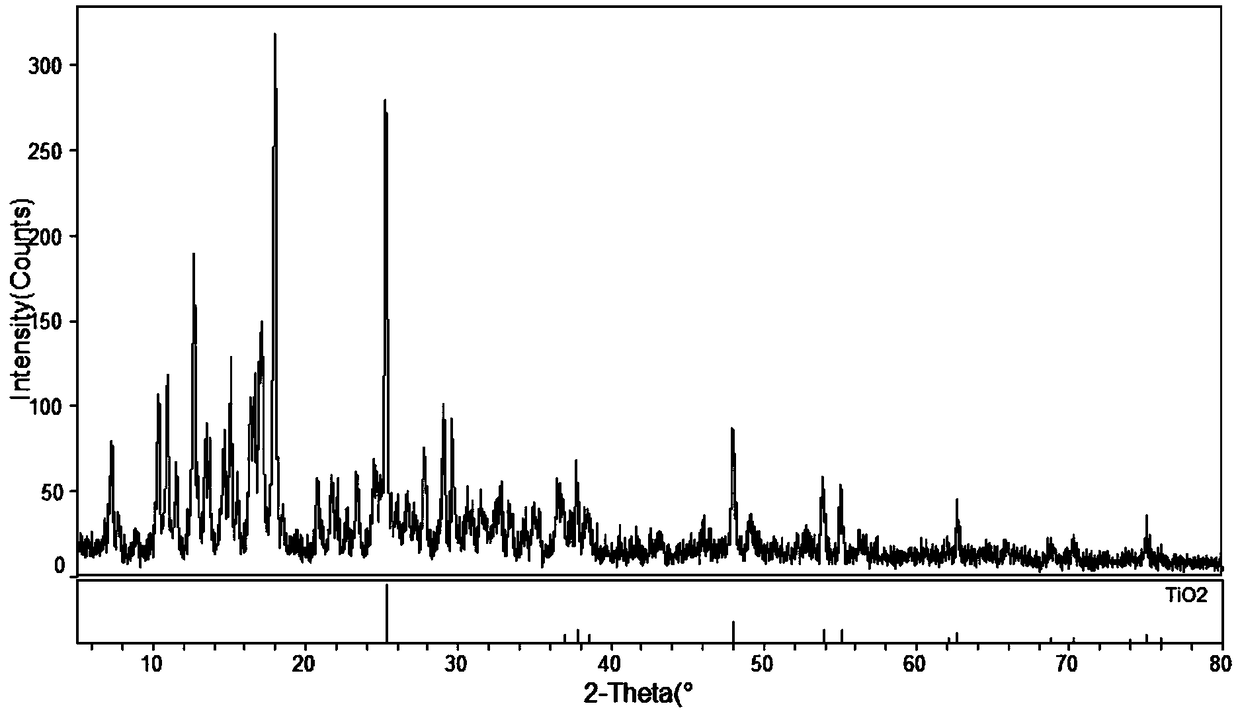

Preparation method of TiO2/ZIF-8 composite photocatalyst

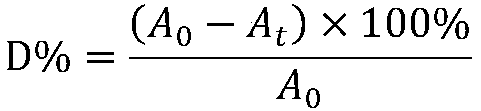

A ZIF-8 and composite light technology, applied in the field of photocatalysis, can solve the problems of difficult loading of ZIF-8, achieve high thermal stability, wide application range, and improve the effect of catalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

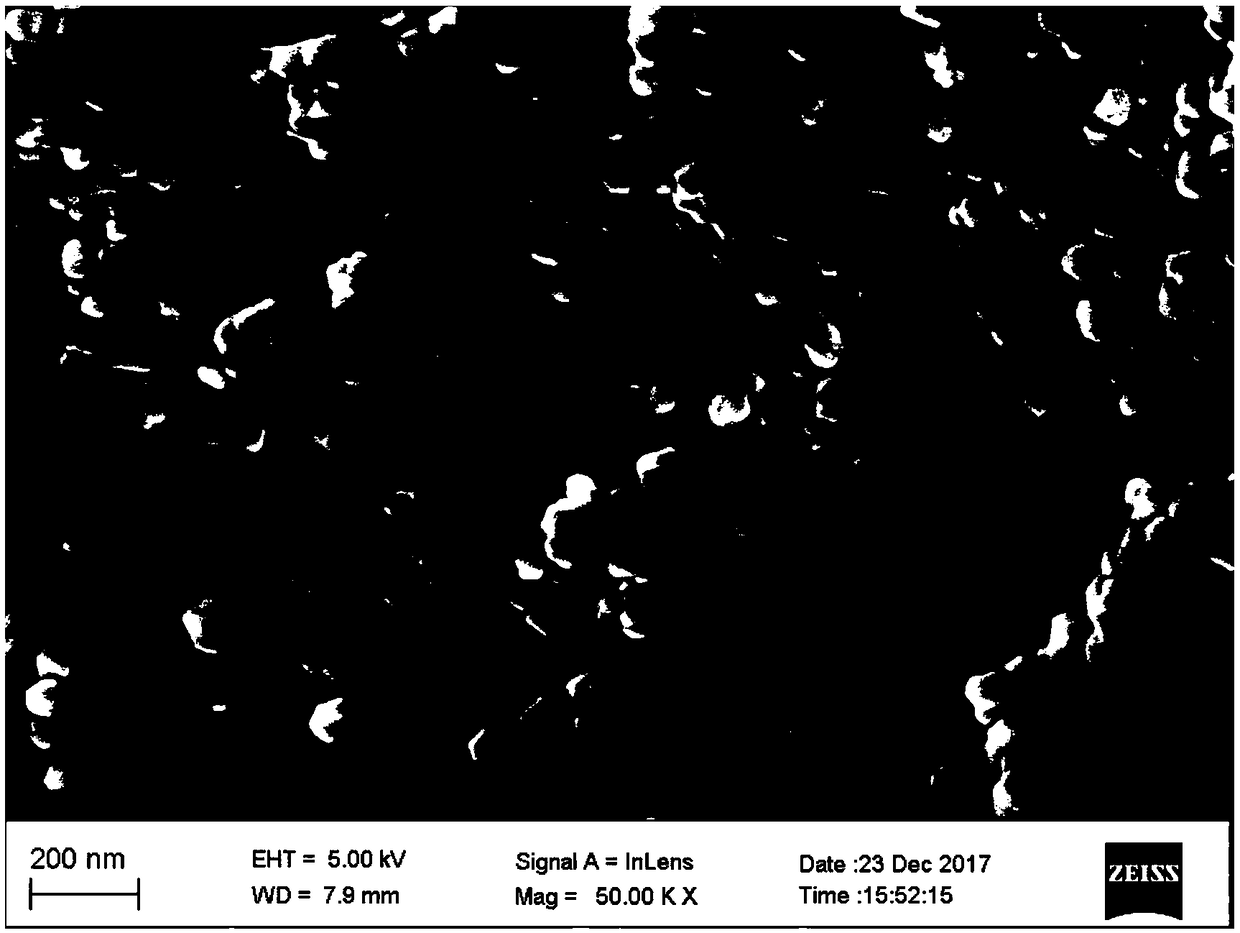

[0025] The embodiment of the present invention provides a kind of TiO 2 The preparation method of / ZIF-8 composite photocatalyst comprises the following steps:

[0026] S10, solvothermal reaction is performed on the mixed solution of soluble zinc salt, 2-methylimidazole and the first organic solvent, so that 2-methylimidazole is deprotonated and zinc ions are self-assembled into ZIF-8, filtered, washed, dried and then ground Obtain ZIF-8 powder;

[0027] S20, causing the hydrolyzable titanium source to undergo a hydrolysis reaction with water in a second organic solvent to obtain a first solution containing nano-titanium dioxide sol;

[0028] S30, concentrating the first solution, increasing the concentration of the nano-titanium dioxide sol, to obtain a second solution; and

[0029] S40, adding the ZIF-8 powder to the second solution, thoroughly mixing by ultrasonic vibration, filtering, washing and drying to obtain TiO 2 / ZIF-8 composite photocatalyst.

[0030] TiO provid...

Embodiment 1

[0050] S10, first add 0.89g of Zn(NO 3 ) 2 ·6H 2 O and 0.49 g of 2-methylimidazole were dissolved in 80 ml of N,N-dimethylformamide (DMF), and then the mixed solution was transferred to a tetrafluoroethylene-lined autoclave at 5 °C min -1 The heating rate was raised to 140°C, reacted for 24 hours, and centrifuged to obtain a solid. The solid was washed with 50ml of DMF and methanol three times, and then placed in an oven at 80°C for overnight drying. After drying, it is ground into powder to obtain ZIF-8 powder.

[0051] S22, take 20ml of absolute ethanol and add it to a clean and dry flask, drop 4 drops of 0.2ml glacial acetic acid using a rubber dropper, and stir magnetically for 5 minutes; take 2ml tetrabutyl titanate and add it to the above mixture, and stir magnetically for 5 minutes; Slowly add 38ml of deionized water dropwise while stirring. The dropwise addition time is more than 15min. After the dropwise addition, the solution is heated to 45°C and continuously sti...

Embodiment 2

[0056] The preparation method is basically the same as that of Example 1, except that in step S30, 1 / 2 of the volume of the first solution is evaporated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com