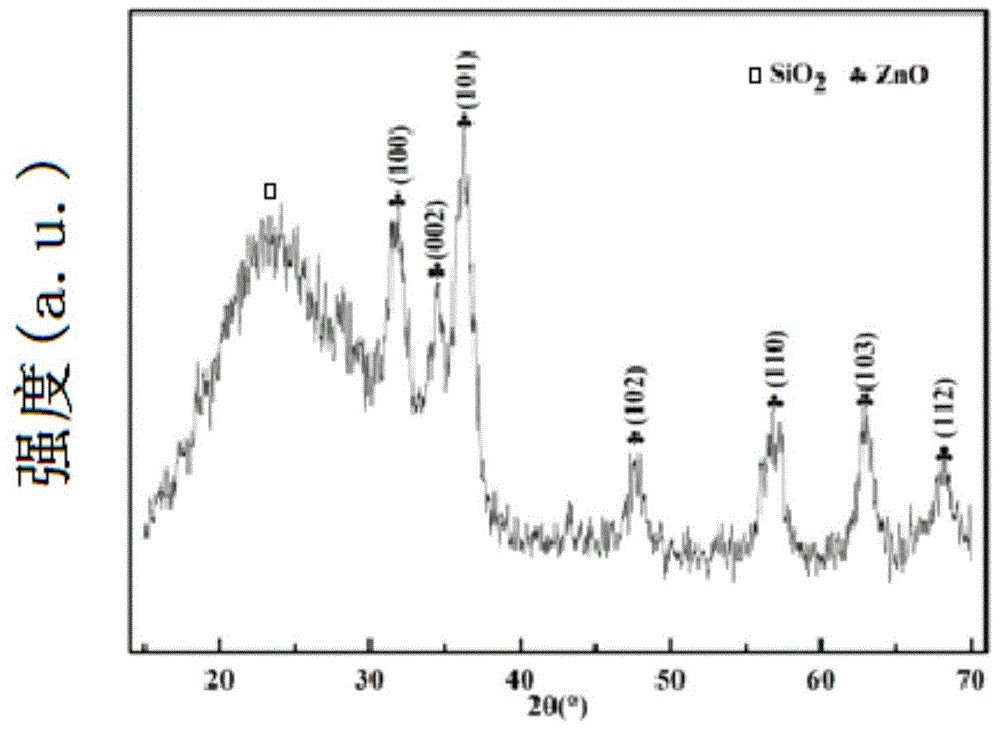

Preparation method of red photonic crystal structure color thin film with photo-catalytic effect

A photonic crystal and photocatalytic technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problem of unexplained photocatalytic performance, etc., and achieve the effect of enhanced catalytic degradation efficiency, bright color, and not easy to fade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a red photonic crystal structural color thin film with photocatalytic effect, comprising the following steps:

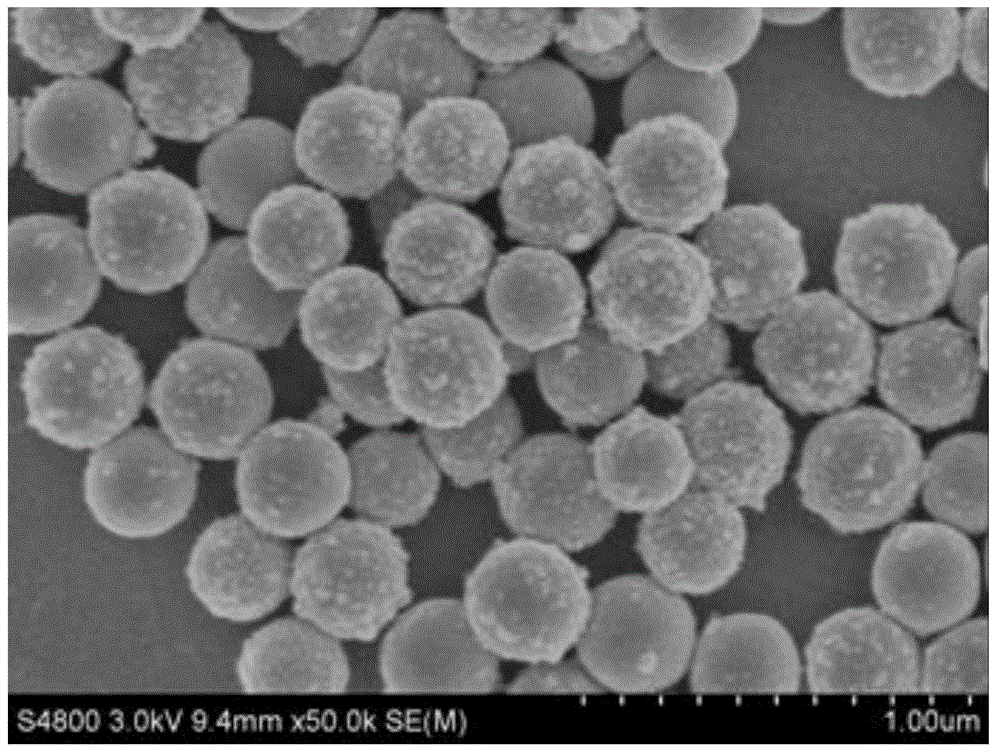

[0036] (1) Weigh SiO with a particle size of 285±5nm according to the mass ratio of 1:3 2 A few grams of microsphere powder and polyvinylpyrrolidone (PVP), mix evenly and place in a beaker, according to every 2.0g SiO 2 Add 100mL of water to the microsphere powder and add deionized water to the beaker, stir and mix with magnetic force, filter after reacting for 4 hours, wash, centrifuge and dry the precipitate to obtain PVP-modified SiO 2 Microspheres;

[0037] Among them, the centrifugation is performed at 7000r / min for 12 minutes, the washing is to wash the precipitate with deionized water for 2 to 4 times, and then with absolute ethanol for 2 to 4 times; the drying is carried out at 70°C.

[0038] (2) Accurately weigh step (1) to obtain SiO modified by PVP 2 Add 0.25 g of microspheres into 10 mL of absolute ethanol and mix ultrasoni...

Embodiment 2

[0055] A preparation method of a red photonic crystal structural color thin film with photocatalytic effect, comprising the following steps:

[0056] (1) Weigh SiO with a particle size of 285±5nm at a mass ratio of 1:2.5 2 Several grams of microsphere powder and polyvinylpyrrolidone (PVP), mix evenly and place in a beaker, according to every 1.5g SiO 2 Add 100mL water to the microsphere powder and add deionized water to the beaker, stir and mix with magnetic force, wash, centrifuge and dry after reacting for 3 hours to get PVP-modified SiO 2 Microspheres;

[0057] Among them, centrifugation is performed at 4000r / min for 20 minutes, washing is performed by first washing the precipitate with deionized water for 2 to 4 times, and then washing with absolute ethanol for 2 to 4 times; drying is performed at 80°C.

[0058] (2) Accurately weigh step (1) to obtain SiO modified by PVP 2 Add 0.2 g of microspheres into 10 mL of absolute ethanol and mix ultrasonically for 20 min to obta...

Embodiment 3

[0067] A preparation method of a red photonic crystal structural color thin film with photocatalytic effect, comprising the following steps:

[0068] (1) Weigh SiO with a particle size of 285±5nm according to the mass ratio of 1:2 2 A few grams of microsphere powder and polyvinylpyrrolidone (PVP), mix evenly and place in a beaker, according to every 2.0g SiO 2 Add 100mL water to the microsphere powder and add deionized water to the beaker, stir and mix with magnetic force, filter after reacting for 3 hours, wash, centrifuge and dry the precipitate to obtain PVP-modified SiO 2 Microspheres;

[0069] Among them, centrifugation is performed at 5000r / min for 15 minutes, washing is performed by first washing the precipitate with deionized water for 2 to 4 times, and then washing with absolute ethanol for 2 to 4 times; drying is performed at 70°C.

[0070] (2) Accurately weigh step (1) to obtain SiO modified by PVP 2 Add 0.15 g of microspheres into 10 mL of absolute ethanol and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com