Preparation method and application of a metal cluster photostable catalyst

A technology of light stability and metal clusters, which is applied in the field of preparation of metal cluster light-stable catalysts, can solve the problems of the catalytic activity and stability of metal clusters on the surface properties, and achieve sustainable development and reduce agglomeration , extensive practical value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

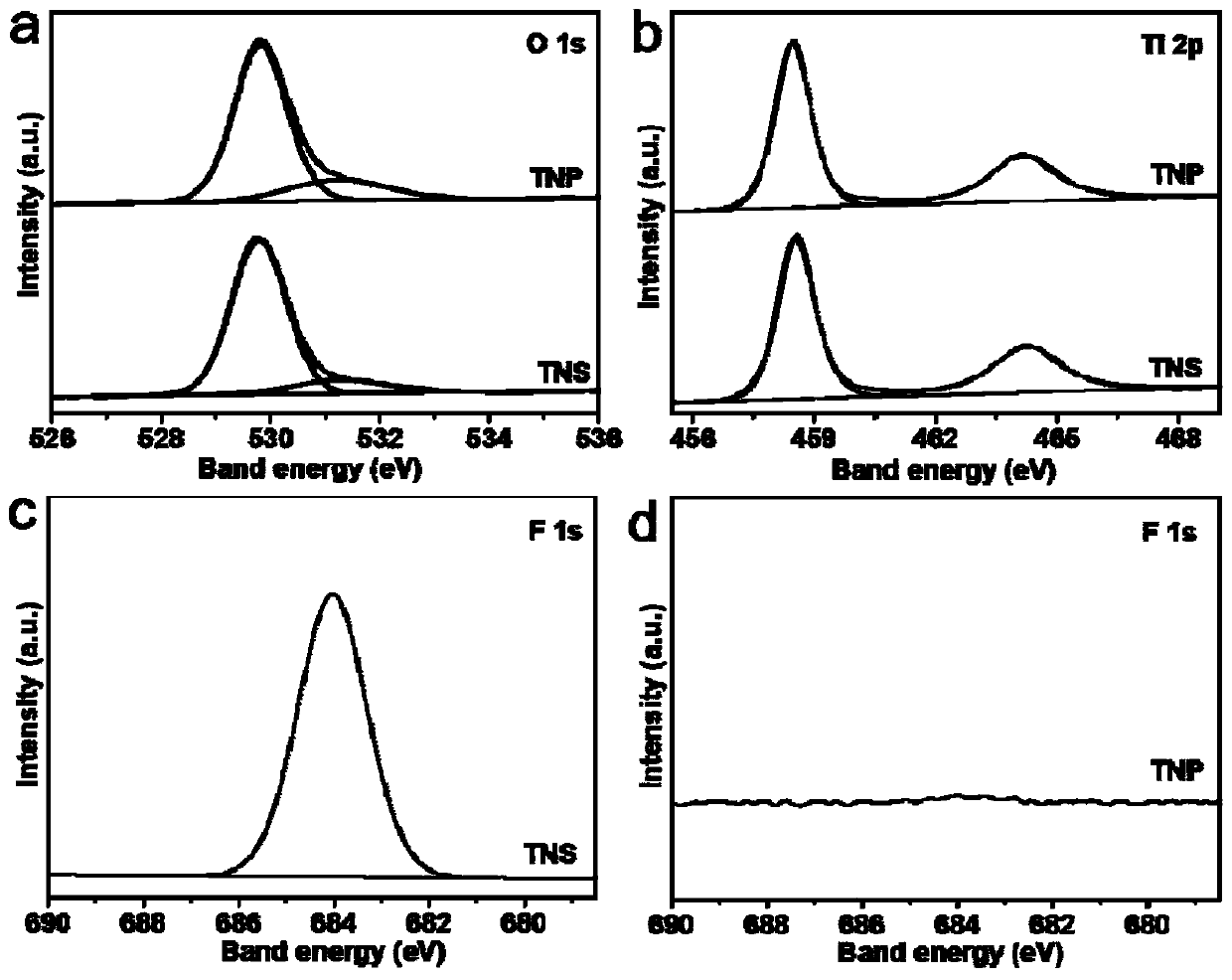

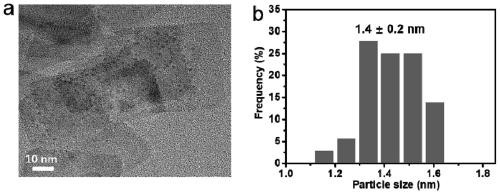

[0030] Please check image 3 , a metal cluster light-stable catalyst of the present embodiment is a nano-gold cluster-titanium dioxide nanosheet (TSBA) with surface regulation and interface modification, and its preparation steps are as follows:

[0031] (1) Preparation of titanium dioxide nanomaterials: 5 mL of n-tetrabutyl titanate (Ti(OBu) 4 ) and 1mL of hydrofluoric acid were mixed and added to the reaction kettle to react at 180°C for 24h, then cooled, centrifuged, washed, and dried to obtain titanium dioxide nanosheets;

[0032] (2) Preparation of interface-modified titanium dioxide nanomaterials: disperse 0.4 g of titanium dioxide nanosheets into 200 mL of ethanol solution, then add 4 mL of branched polyethyleneimine aqueous solution (86 mg / mL), and reflux at 60 ° C for 4 h to obtain the interface Modified titanium dioxide nanosheets;

[0033] (3) Preparation of nano-gold clusters: Disperse 0.24g of gold chloride trihydrate into 300mL of water, add 0.276g of cysteine ...

Embodiment 2

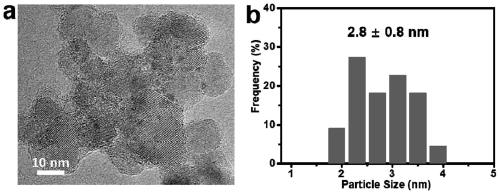

[0036] Please check figure 2 , a metal cluster light-stable catalyst of the present embodiment is an interface-modified nano-gold cluster-titania nanoparticle (TPBA), and its preparation steps are as follows:

[0037] (1) Preparation of titanium dioxide nanomaterials: 5 mL of n-tetrabutyl titanate (Ti(OBu) 4 ) and 1mL of water were mixed and added to the reaction kettle to react at 180°C for 24h, then cooled, centrifuged, washed, and dried to obtain titanium dioxide nanoparticles;

[0038] (2) Preparation of interface-modified titanium dioxide nanomaterials: disperse 0.4 g of titanium dioxide nanoparticles into 200 mL of ethanol solution, then add 4 mL of branched polyethyleneimine aqueous solution (86 mg / mL), and reflux at 60 ° C for 4 h to obtain the interface Modified titanium dioxide nanoparticles;

[0039] (3) Preparation of nano-gold clusters: Disperse 0.24g of gold chloride trihydrate into 300mL of water, add 0.276g of cysteine and stir until colorless, then reflux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com