Preparing method for CdSe/CdZnSeS/ZnS core-shell quantum dots

A technology of core-shell quantum dots and molarity, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unfavorable large-scale production, complex synthesis steps, and application limitations of quantum dots, so as to facilitate large-scale production and synthesis The effect of simple steps and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

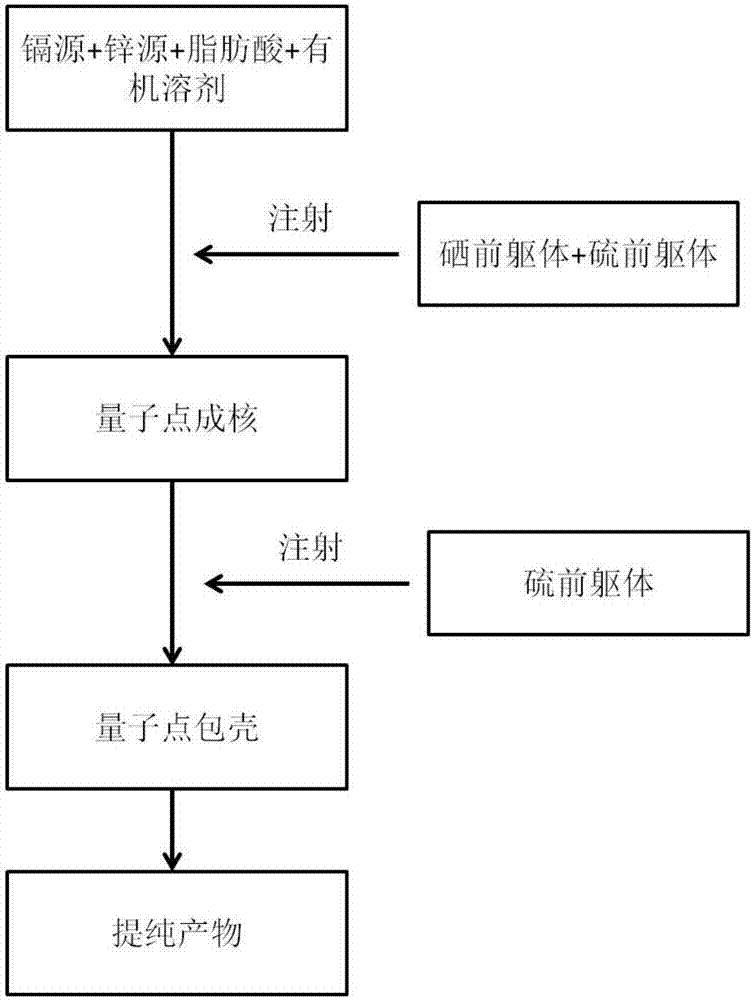

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 sulfur precursor

[0031] 50g of dodecyl mercaptan and 100g of octadecene were stirred and mixed at room temperature to prepare the sulfur precursor.

Embodiment 2

[0032] The preparation of embodiment 2 sulfur precursor

[0033] 40g of octyl mercaptan and 60g of trioctylamine were stirred and mixed at room temperature to prepare the sulfur precursor.

Embodiment 3

[0034] The preparation of embodiment 3 sulfur precursor

[0035] In a 250ml flask, mix 3.2g of sulfur powder and 100g of octadecene, under the protection of argon, heat to 280 degrees, the solution is clear and transparent, then cool down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com