Light emitting diode (LED) and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low light-emitting efficiency of light-emitting diodes, and achieve the effects of improving external quantum efficiency, improving internal quantum efficiency, and improving light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

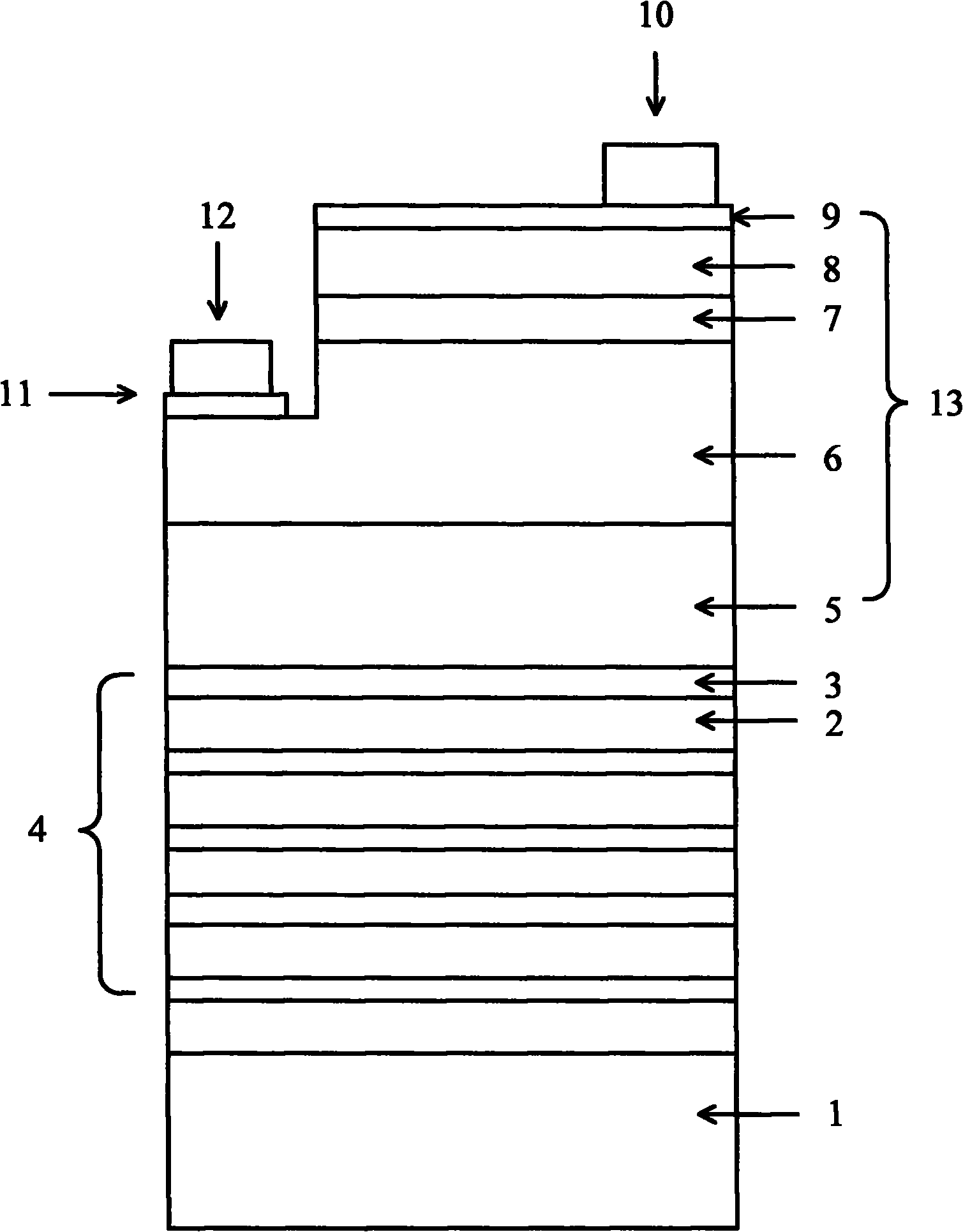

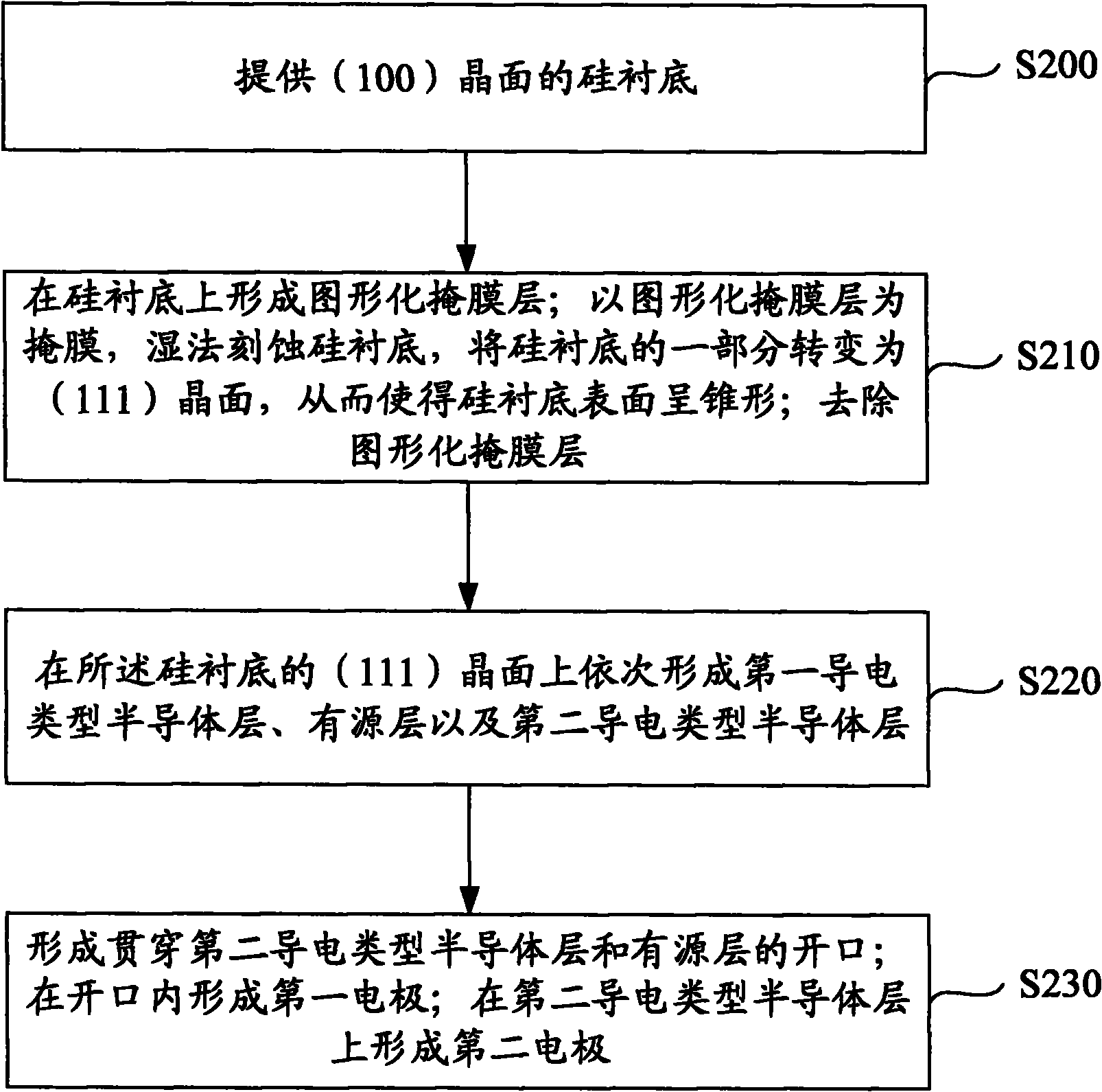

[0022] Please refer to figure 2 , which is a schematic flow chart of a method for manufacturing a light-emitting diode according to an embodiment of the present invention. In combination with this figure, the method includes the following steps:

[0023] Step S200, providing a silicon substrate with a (100) crystal plane;

[0024] Step S210, forming a patterned mask layer on the silicon substrate; using the patterned mask layer as a mask, wet etching the silicon substrate to transform a part of the silicon substrate into ( 111) a crystal plane, so that the surface of the silicon substrate is tapered; removing the patterned mask layer;

[0025] Step S220, sequentially forming a first conductivity type semiconductor layer, an active layer, and a second conductivity type semiconductor layer on the (111) crystal plane of the silicon substrate;

[0026] Step S230, forming an opening through the semiconductor layer of the second conductivity type and the active layer; forming a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com