Colorimetric kit for rapidly detecting chicken egg-yolk antibody

A technology of egg yolk antibody and polymer, applied in the field of biological detection, can solve the problems of low detection rate of antibodies, great influence of antibody interference, and long detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Magnetic Nanoparticles Fe 3 o 4 Preparation of NPs

[0028] With vigorous stirring, 2.7 g FeCl 3 ·6H 2 O and 7.2 g NaAc were dissolved in 100 mL of ethylene glycol to obtain a homogeneous brown-yellow solution; the homogeneous brown-yellow solution was transferred to a Teflon-lined reactor and sealed, and reacted in an oven at 200 °C for 8 h , after the reaction kettle was cooled to room temperature, black magnetite particles were separated from the reaction solution by means of permanent magnets; the black magnetite particles were washed alternately with absolute ethanol and ultrapure water for 6 to 7 times, and vacuumed at 60 °C After drying for 12 h, the magnetic nanoparticles Fe 3 o 4 NPs;

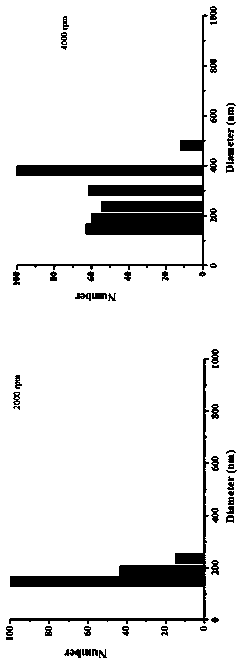

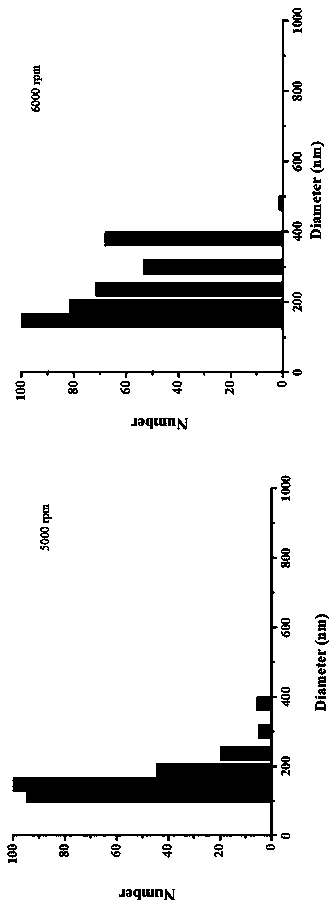

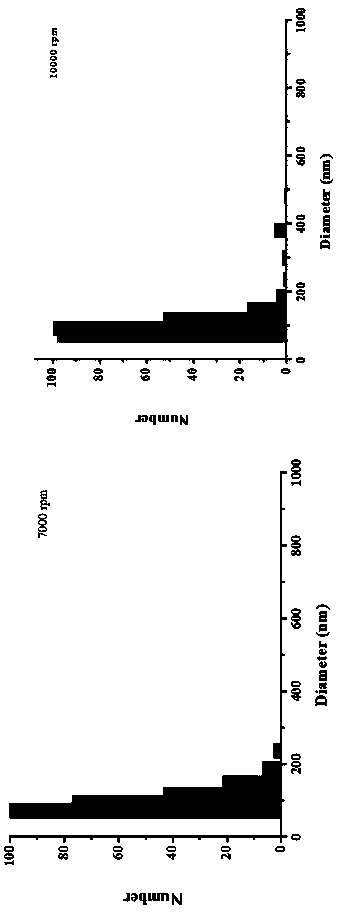

[0029] In order to obtain magnetic nanoparticles with uniform size, this study adopts the centrifugal precipitation method to separate the magnetic nanoparticles, and uses dynamic light scattering (DLS) to characterize the obtained magnetic nanoparticles. The r...

Embodiment 2

[0030] Example 2 Magnetic nanoparticles Fe 3 o 4 Preparation of NPs

[0031] With vigorous stirring, 2.7 g FeCl 3 ·6H 2 O and 7.2 g NaAc were dissolved in 100 mL of ethylene glycol to obtain a homogeneous brown-yellow solution; the homogeneous brown-yellow solution was transferred to a Teflon-lined reactor and sealed, and reacted in an oven at 180 °C for 10 h , after the reaction kettle was cooled to room temperature, black magnetite particles were separated from the reaction solution by means of permanent magnets; the black magnetite particles were washed alternately with absolute ethanol and ultrapure water for 6 to 7 times, and vacuumed at 60 °C After drying for 18 h, the magnetic nanoparticles Fe 3 o 4 NPs.

Embodiment 3

[0032] Example 3 Magnetic nanoparticles Fe 3 o 4 Preparation of NPs

[0033] With vigorous stirring, 2.7 g FeCl 3 ·6H 2 O and 7.2 g NaAc were dissolved in 100 mL of ethylene glycol to obtain a homogeneous brown-yellow solution; the homogeneous brown-yellow solution was transferred to a Teflon-lined reactor and sealed, and reacted in an oven at 200 ° C for 18 h. After the reactor is cooled to room temperature, black magnetite particles are separated from the reaction solution by means of a permanent magnet; the black magnetite particles are alternately washed several times with absolute ethanol and ultrapure water, and vacuum-dried at 55°C for 15 hours. Magnetic nanoparticles Fe 3 o 4 NPs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com