Sealing structure and method for wall hole

A wall and hole technology, applied in building construction, building maintenance, construction, etc., can solve problems such as increased safety hazards, external wall leakage, complex process, etc., to reduce safety hazards, short construction period, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Such as Figure 4 As shown, when there is an original PVC pipe 3 in the hole of the wall, the method for plugging the hole of the wall includes the following steps: the first step is to clean up the residue in the original PVC pipe 3 with the air gun of a small air compressor; The original PVC pipe 3 exposed on the wall, in order to remove the original PVC pipe 3 once with a shovel to avoid secondary cleaning, it is necessary to mark the joint between the original PVC pipe 3 and the wall with a shovel. Flat with the wall to reduce the occurrence of deviation; the third step is to use a brush to clean the residue around the wall hole 2; the fourth step is to hammer the waterproof sealing plug 7 from the outer wall into the wall hole 2 with a hammer In the original PVC pipe 3; the fifth step, fill the flame-retardant polyurethane foaming agent 8 into the original PVC pipe 3 in the hole 2 of the wall; in the sixth step, use a spatula to flush with the wall 1 to remove resi...

Embodiment 2

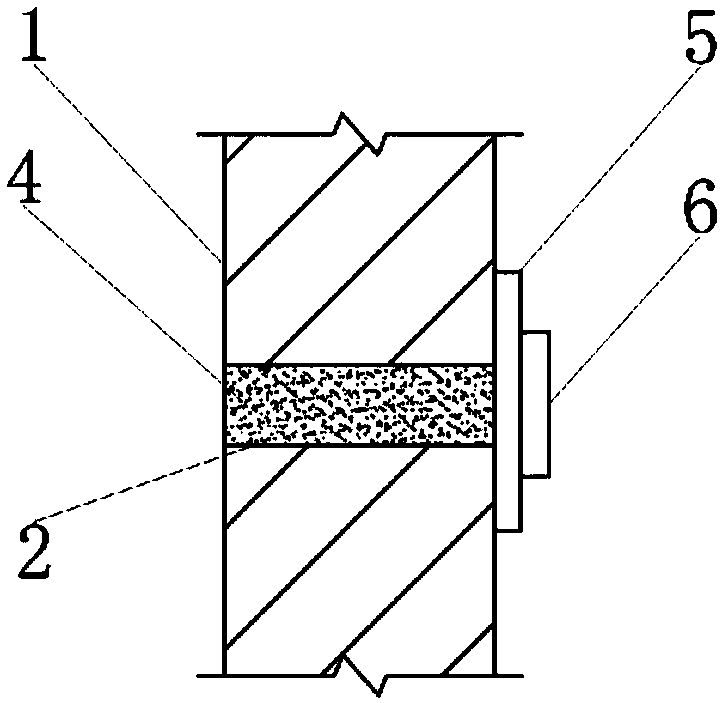

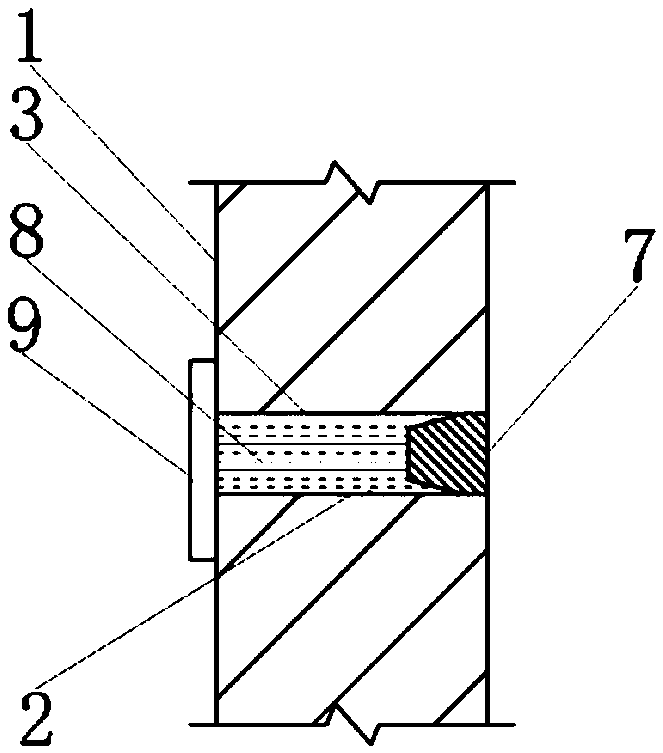

[0064] Such as Figure 2a and Figure 5 As shown, when there is no PVC pipe in the hole in the wall, the method for sealing the hole in the wall includes the following steps: the first step is to clean the residue in the hole 2 with the air gun of a small air compressor; the second step is to clean the wall with a brush The residue around the body hole 2; the third step is to hammer the waterproof sealing plug 7 from the outer wall into the wall hole 2 with a hammer; the fourth step is to fill the flame-retardant polyurethane foaming agent 8 into the wall hole 2; The fifth step is to remove the residual foaming agent flush with the wall 1 with a spatula; the sixth step is to use plastering mortar to smooth the inner wall.

Embodiment 3

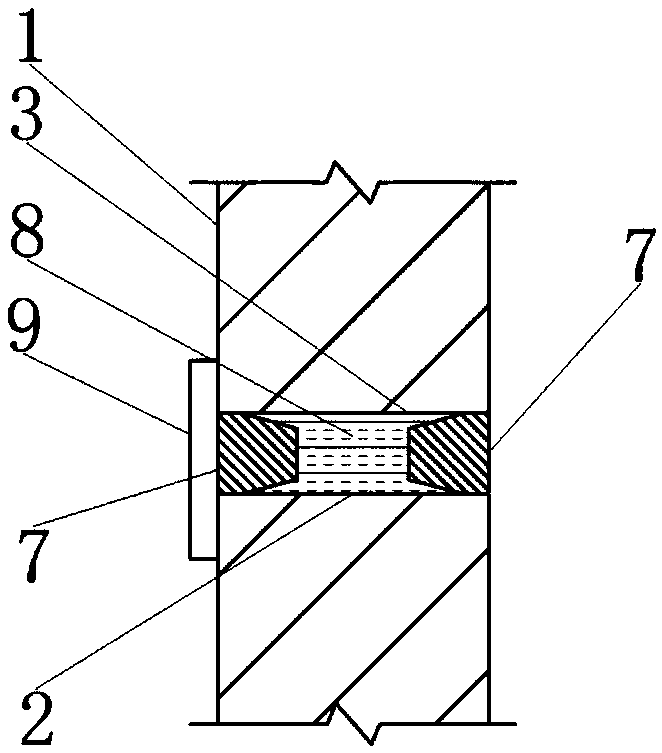

[0066] Such as Figure 2b and Figure 6 As shown, when there is no PVC pipe in the hole in the wall, the method for sealing the hole in the wall includes the following steps: the first step is to clean the residue in the hole 2 with the air gun of a small air compressor; the second step is to clean the wall with a brush The residue around the body hole 2; the third step is to hammer the waterproof sealing plug 7 from the outer wall into the wall hole 2 with a hammer; the fourth step is to fill the flame-retardant polyurethane foaming agent 8 into the wall hole 2; The fifth step is to hammer the waterproof sealing plug 7 from the inner wall into the wall hole 2 with a hammer; the sixth step is to remove the residual foaming agent with a spatula flush with the wall 1; the seventh step is to use plastering glue Slurry is used to smooth the inner wall surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com