Anti-coking and anti-slagging coating material for four tubes of boiler and preparation method of anti-coking and anti-slagging coating material

A coating material and anti-coking technology, applied in coatings, fireproof coatings, alkali metal silicate coatings, etc., can solve problems such as high construction cost, coke drop and fire extinguishing, easy coking and slagging, etc., and achieve anti-coking Excellent slag performance, reduced engineering quantity, and good bonding and adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

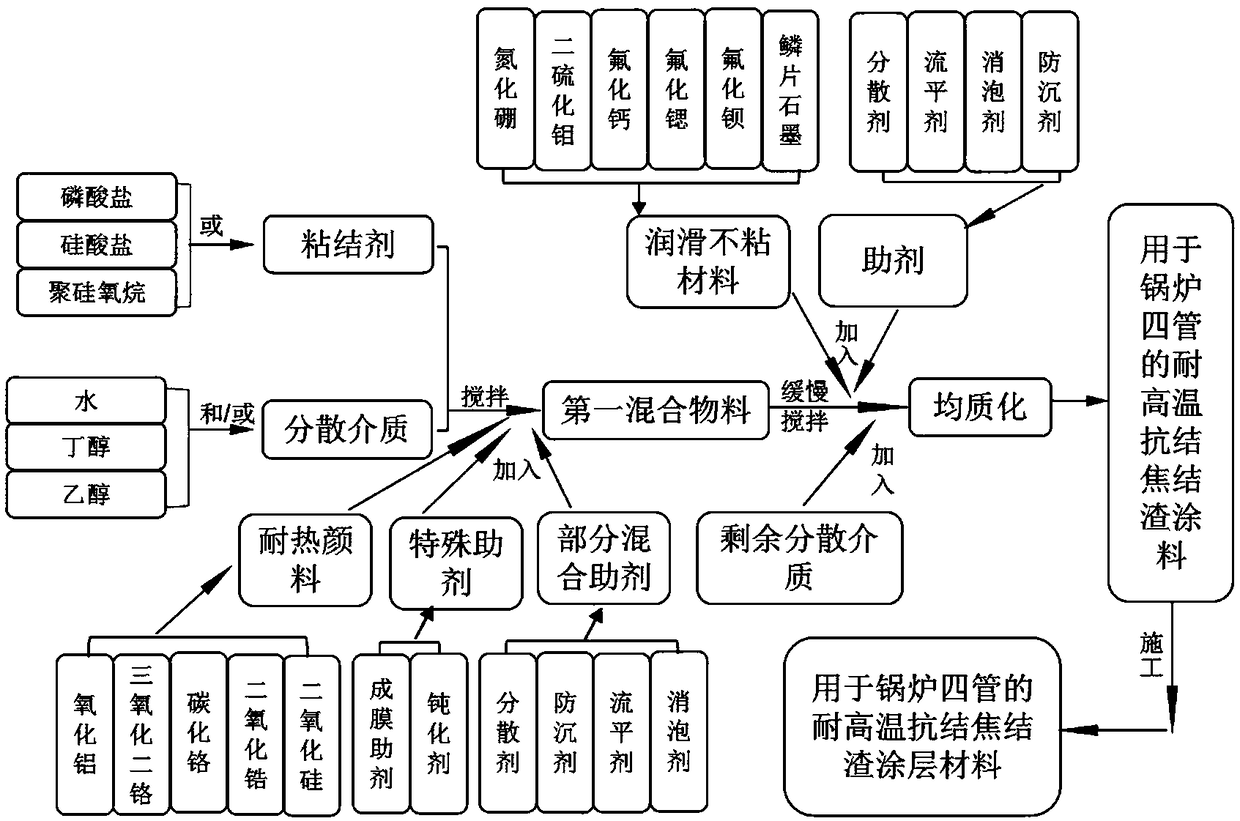

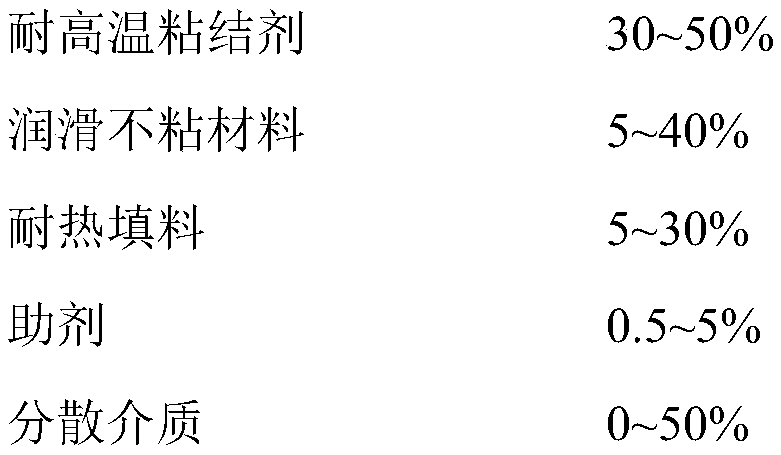

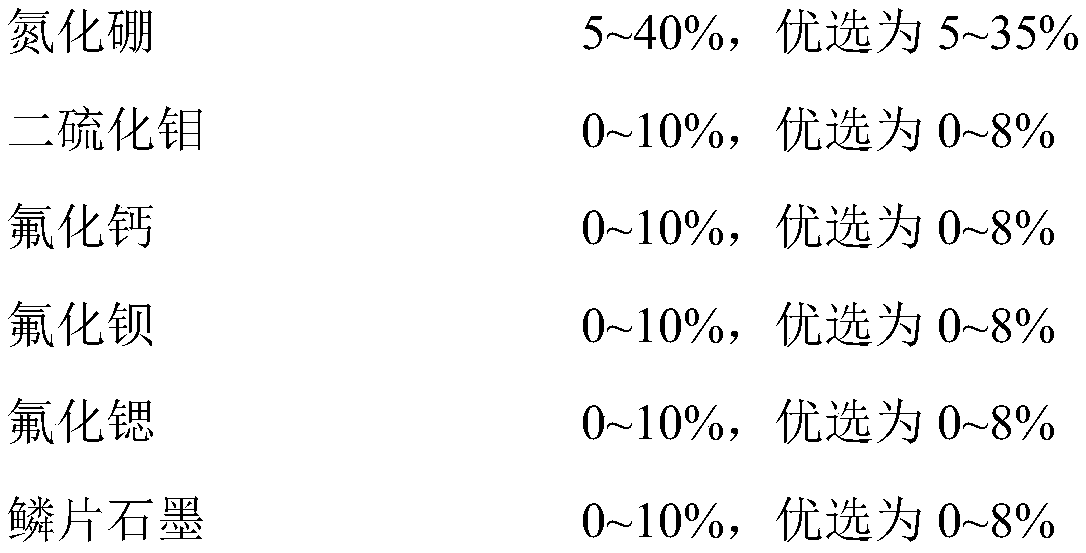

Method used

Image

Examples

Embodiment 1

[0049] Raw material ratio: binder aluminum monohydrogen phosphate 15.0g, magnesium dihydrogen phosphate 15.0g, lubricating and non-stick material boron nitride 5.0g, heat-resistant pigment alumina 30.0g, passivator 3.0g, mixing aid 2.0g , Dispersion medium water 30.0g.

[0050] Coating preparation: Take part of water, mixing aid, passivating agent, binder aluminum monohydrogen phosphate, magnesium dihydrogen phosphate, and heat-resistant pigment aluminum oxide and add them to the stirring tank, and stir for 10 minutes at a line speed of 1.0m / s to obtain the first mixed material;

[0051] Add the lubricating and non-stick material boron nitride and the rest of the water to the first mixed material, use a temperature-controllable high-pressure homogeneous disperser to completely homogenize the coating at a temperature of 4°C and a pressure of 150MPa, and filter until the particle size is less than 25μm The material is discharged to obtain an anti-coking and slagging coating mat...

Embodiment 2

[0061] Raw material ratio: binder aluminum dihydrogen phosphate 20.0g, iron dihydrogen phosphate 10.0g, manganese dihydrogen phosphate 5.0g, lubricating and non-stick material boron nitride 40.0g, heat-resistant pigment chromium carbide 5.0g, passivator 3.0 g, 2.0 g of mixing aids, and 15.0 g of water as a dispersion medium.

[0062] Coating preparation: Take part of water, mixing aid, passivator, binder aluminum dihydrogen phosphate, iron dihydrogen phosphate, manganese dihydrogen phosphate, and heat-resistant pigment chromium carbide and add them to the stirring tank, and the online speed is 1.0m / s Down stirring 30min, obtain the first mixed material;

[0063] Add the lubricating and non-stick material boron nitride and the rest of the water to the first mixed material, use a temperature-controllable high-pressure homogeneous disperser to completely homogenize the coating at a temperature of 15°C and a pressure of 200MPa, and filter until the particle size is less than 25μm ...

Embodiment 3

[0073] Raw material ratio: binder magnesium monohydrogen phosphate 25.0g, calcium dihydrogen phosphate 15.0g, copper monohydrogen phosphate 10.0g, lubricating and non-stick material boron nitride 5.0g, molybdenum disulfide 3.0g, heat-resistant pigment zirconia 10.0 g, passivator 3.0g, mixing aid 3.0g, dispersion medium water 26.0g.

[0074] Coating preparation: Take part of water, mixing aid, passivator, binder magnesium monohydrogen phosphate, calcium dihydrogen phosphate, copper monohydrogen phosphate, heat-resistant pigment zirconia and add it to the stirring tank, and the line speed is 3.0m / s Down stirring 30min, obtain the first mixed material;

[0075] Add lubricating and non-stick materials boron nitride, molybdenum disulfide and the rest of water to the first mixed material, and use a temperature-controllable high-pressure homogeneous disperser to completely homogenize the coating at a temperature of 25 ° C and a pressure of 190 MPa until the particle size After the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com