Metal organic framework forming body and preparation method thereof

A metal-organic framework and molding technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low MOFs content, low compressive mechanical strength, poor hydrophobic performance, etc. Abrasion resistance, good hydrophobicity and water stability, the effect of increasing the value of industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

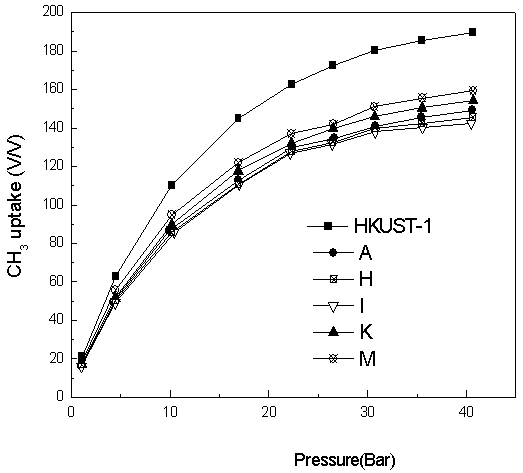

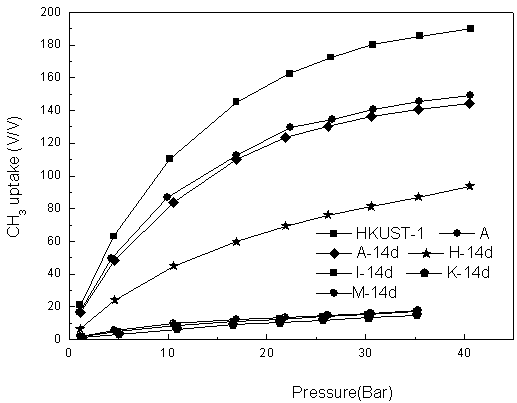

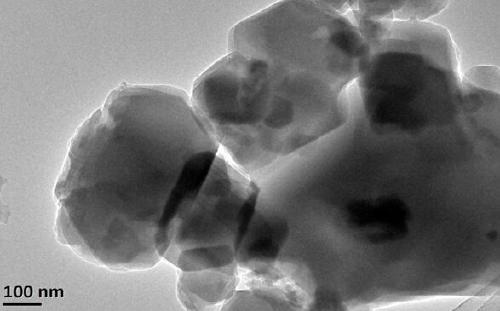

[0035] (1) The specific surface area of 50g is 1623 m 2 / g, the pore volume is 0.71 cm 3 / g of HKUST-1 powder, 2.5g of alumina, 2.5g of methylcellulose and 14g of water were mixed, then added to the granulator for granulation, and the obtained pellets were dried at 100°C for 10h, Calcined for 10 hours, a spherical HKUST-1 molded body was obtained, with an average diameter of 1.0 mm.

[0036] (2) Add 50g of spherical HKUST-1 shaped body and 10g of polyvinylpyrrolidone into 500ml of ethanol, and ultrasonicate at 30kHz for 1h to obtain a feed solution containing modified spherical HKUST-1 shaped body.

[0037] (3) Slowly add 7g of methyltrimethoxysilane, 1g of nitric acid with a mass concentration of 1wt%, and 9g of water dropwise into the above-mentioned feed solution, after ultrasonication at 30kHz for 1.5h, age for 6h, filter and separate, wash until neutral, After drying at 100°C for 5 hours, it was fired at 200°C for 10 hours to obtain a spherical HKUST-1 molded body A w...

Embodiment 2

[0041] (1) The specific surface area of 50g is 1623 m 2 / g, the pore volume is 0.71 cm 3 / g of HKUST-1 powder, 2g of alumina, 5g of starch and 20g of water are mixed evenly, then added to a granulator for granulation, and the obtained pellets are dried at 100°C for 15h, and then calcined at 200°C for 8h to obtain Spherical HKUST-1 molded body with an average diameter of 2.0 mm.

[0042] (2) Add 30g of spherical HKUST-1 shaped body and 10g of polyvinylpyrrolidone into 500ml of ethanol, and ultrasonicate at 50kHz for 2h to obtain a feed solution containing modified spherical HKUST-1 shaped body.

[0043] (3) Slowly add 11g of dimethyldimethoxysilane, 0.5g of 1wt% hydrochloric acid and 10g of distilled water dropwise into the above-mentioned feed solution, after ultrasonication at 50kHz for 1.5h, age for 2h, filter and separate, and wash until Neutral, after drying at 100°C for 5 hours, calcining at 200°C for 12 hours, you can get spherical HKUST-1 shaped body B with a silico...

Embodiment 3

[0046] (1) The specific surface area of 50g is 1057m 2 / g, the pore volume is 0.45 cm 3 / g of MOF-5 powder, 10g of alumina, 2g of methyl cellulose and 40g of water were mixed evenly, then added to the granulator for granulation, and the obtained pellets were dried at 80°C for 2h, and then calcined at 200°C for 12h , and a spherical MOF-5 shaped body was obtained with an average diameter of 1.51 mm.

[0047] (2) Add 50g of spherical MOF-5 moldings and 20g of polyvinylpyrrolidone to 500ml of ethanol, and ultrasonicate at 50kHz for 3h to obtain a feed solution containing modified spherical MOF-5 moldings.

[0048] (3) Slowly add 11.5g of methyltriethoxysilane, 2g of acetic acid with a mass concentration of 3wt%, and 20g of distilled water dropwise into the above-mentioned feed liquid, after ultrasonication at 50kHz for 1.5h, age for 3h, filter and separate, and wash until medium After drying at 100°C for 5 hours, and then firing at 200°C for 10 hours, a spherical MOF-5 molded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com