Starch-base styrene-acrylic emulsion and preparation method thereof

A starch-based styrene-acrylic emulsion and a technology of the styrene-acrylic emulsion are applied in the field of starch-based styrene-acrylic emulsion and its preparation, and can solve the problems of high cost, poor water resistance, and more foam, and achieve less foaming, high bonding strength, Good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] On the other hand, the embodiment of the present invention also provides a kind of preparation method of starch-based styrene-acrylic emulsion, it comprises:

[0023] S1. Mix anionic starch and its derivatives with vegetable gum and heat up and cook.

[0024] Specifically, the anionic starch and its derivatives are prepared with water to a concentration of 20-40%, and then vegetable gum is added in an amount of 0.5-1.5%, and the temperature is raised to 90-95° C. and boiled for 0.5-1 hour.

[0025] S2, then lowering the temperature, adding the monomer mixture, initiator and internal crosslinking agent dropwise, and keeping warm.

[0026] Specifically, cool down the material obtained in step S1 to 80-85°C, then dropwise add the monomer mixture, initiator and internal crosslinking agent, drop the monomer mixture, initiator and internal crosslinking agent in 1-3 hours, and keep warm 0.5-2 hours.

[0027] Wherein, the monomer mixture may be mixed and dropped with the inte...

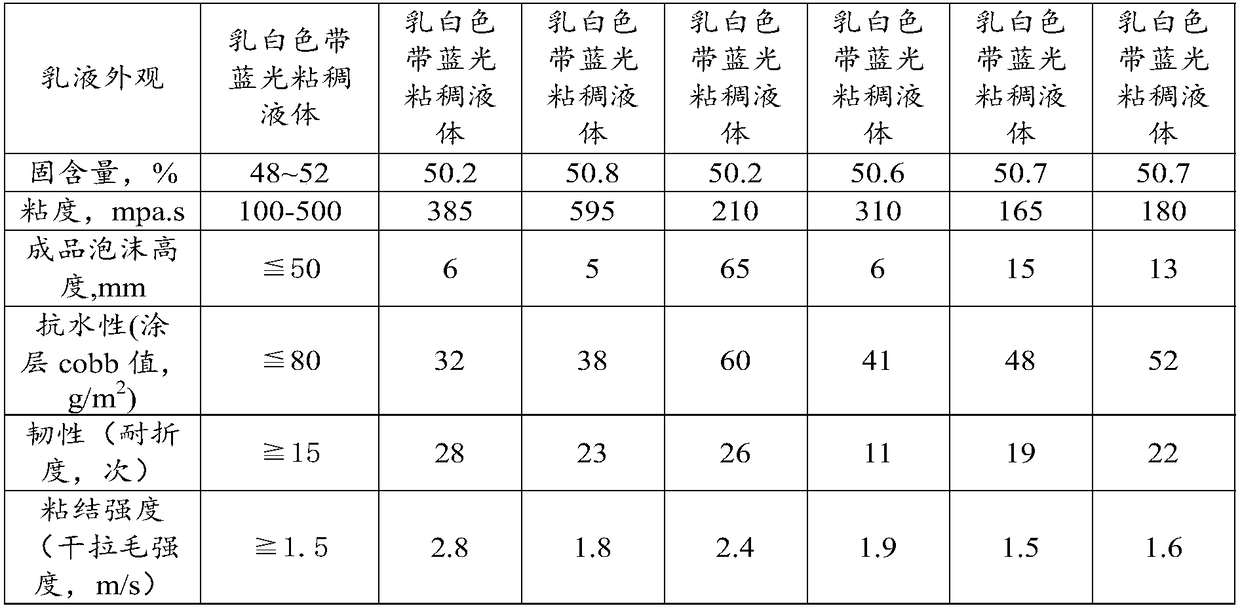

Embodiment 1

[0035] This embodiment provides a starch-based styrene-acrylic emulsion and a preparation method thereof.

[0036] In a four-neck flask with a condenser and a stirring paddle, add 195g of water, start stirring, add 87g of carboxylated starch, add 3.5g of Tianqing gum, heat up to 93°C and cook for 1 hour, then cool down to a material temperature of 85°C. Start to drop 3.5g of 5% potassium persulfate solution and a mixture of 60g of styrene, 4g of acrylic acid, 40g of butyl acrylate, and 3g of N-hydroxyacrylamide at the same time. The latter drops in 80 minutes, and the former drops in 85 minutes. , After dripping, it was kept at this temperature for 2 hours. Lower the temperature of the material to 58°C, adjust the pH value of the material to 7.5, add 4g of aziridine, keep it warm for 1 hour, lower the temperature of the material to 42°C, filter, and discharge the material to obtain the product.

[0037] Actual solid content: 50.2%, viscosity: 385mpa.s, pH value: 7.3

Embodiment 2

[0039] This embodiment provides a starch-based styrene-acrylic emulsion and a preparation method thereof.

[0040] In a four-neck flask with a condenser and a stirring paddle, add 198g of water, start stirring, add 80g of phosphate ester starch, add 4g of gum arabic, heat up to 95°C and cook for 1 hour, cool down to a material temperature of 83°C, and start Add dropwise the mixture of ammonium persulfate solution of 3g 3% concentration and 60g styrene, 3g methacrylic acid, 44g butyl acrylate, 4g acetoacetoxy ethyl methacrylate, the latter dripped in 75 minutes, the former in 80 Minutes drop, after dripping, keep warm at this temperature for 1.5 hours. Lower the temperature of the material to 55°C, adjust the pH of the material to 7.8, add 4g of pentaerythritol glycidyl ether, keep it warm for 1 hour, lower the temperature of the material to 45°C, filter, and discharge the material to obtain the product.

[0041] Actual solid content: 49.8%, viscosity: 425mpa.s, pH value: 7.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com