Joint lubricant and preparation method thereof

A lubricant and bone joint technology, applied in the field of bone joint lubricant and its preparation, can solve the problems of unsatisfactory treatment effect and limited joint lubrication effect, and achieve good shear dilution, good support effect, and strong lubrication effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

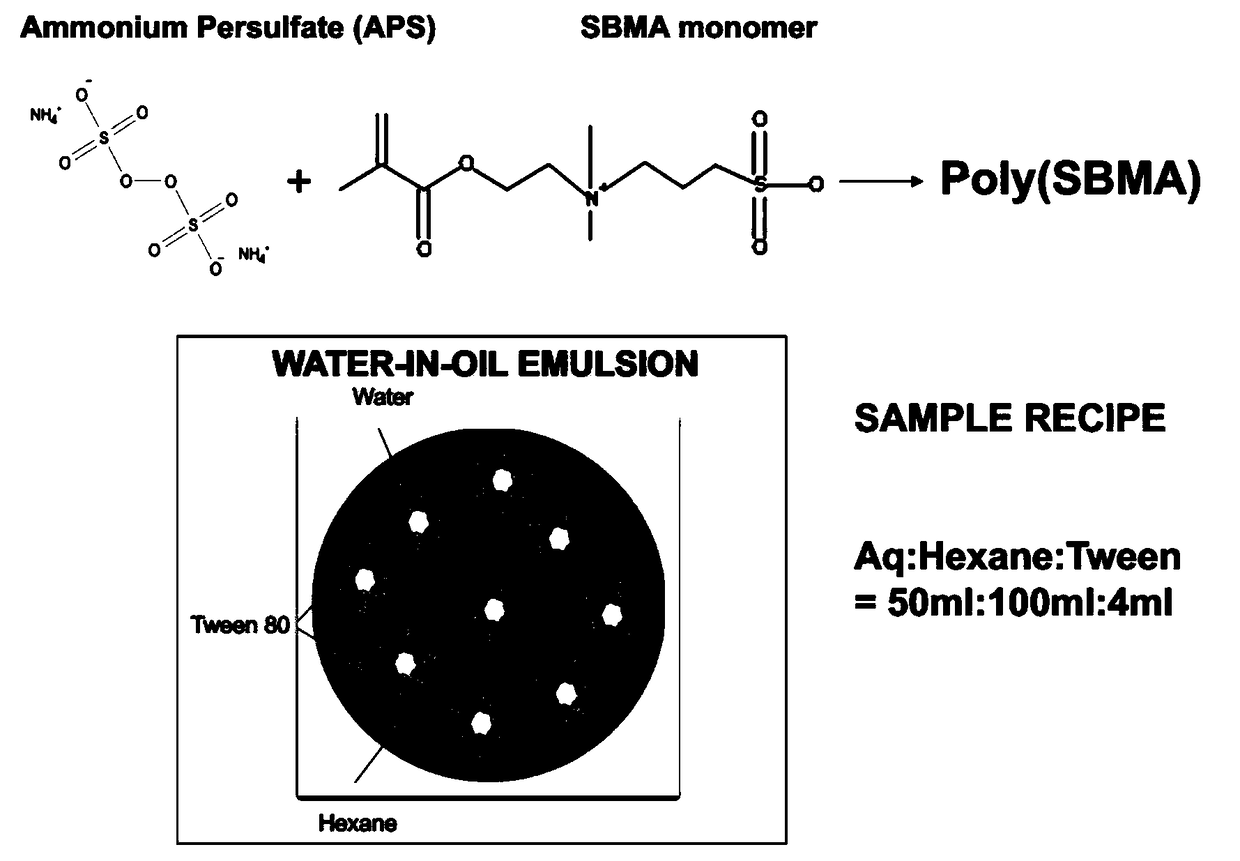

[0026] Experimental example 1 The preparation method of bone joint lubricant of the present invention

[0027] Using 2-methacryloyloxyethylphosphorylcholine (MPC) as amphoteric monomer, methylenebisacrylamide (MBA) as crosslinking agent, ammonium peroxodisulfate (APS) as polymerization initiator, tetramethyl ethylenediamine (TMEDA) as the catalyst. The synthesis of microgels is carried out in the aqueous phase of water-in-oil emulsions, as figure 1 shown.

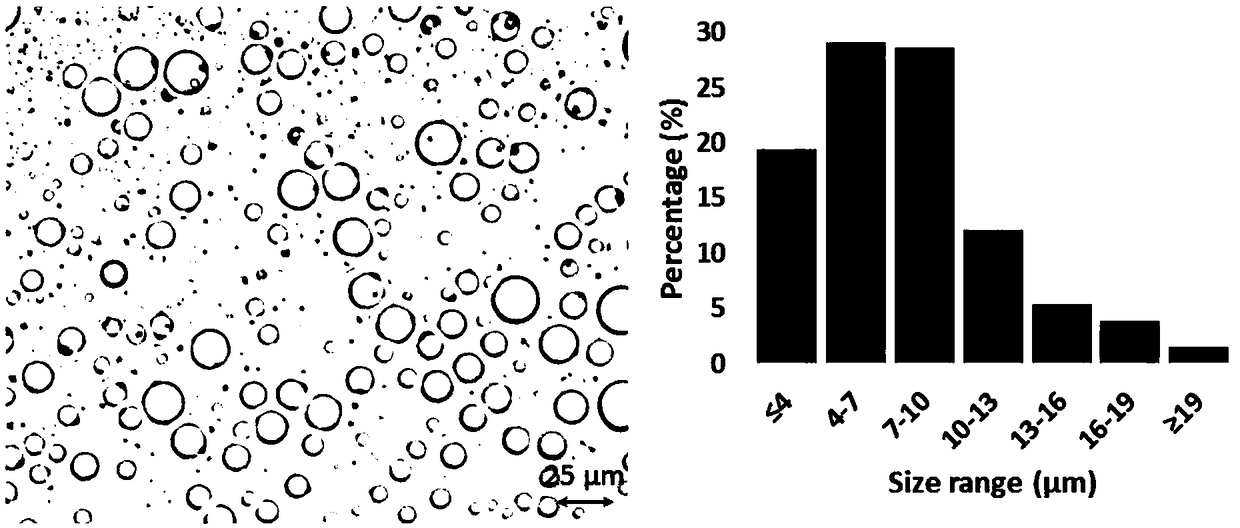

[0028] Dissolve 16.4 mg of amphoteric monomer and 7.7 mg of cross-linking agent in 5 mL of deionized water to form an aqueous phase; dissolve 0.2 mL of Tween 80 and 0.2 mL of Span 80 in 10 mL of hexane to form an oil phase. Mix the water phase and the oil phase in a 100mL flask, stir vigorously for 5min, and sonicate for 30min to form a microemulsion. Purify the flask with argon at room temperature to degas the solution, then add 0.06 mL of APS with a concentration of 0.22 mol / L and 0.02 mL of TMEDA, respectively. The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com