Polyolefin fiber and method for producing same

A technology of polyolefin system and manufacturing method, which is applied in the direction of single-component polyolefin artificial filament, single-component polypropylene artificial filament, fiber treatment, etc., which can solve the limitation of fiber input, low recyclability, and production speed Variation and other problems, to achieve the effect of inhibiting fibrillation, high tensile strength, high nodular strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

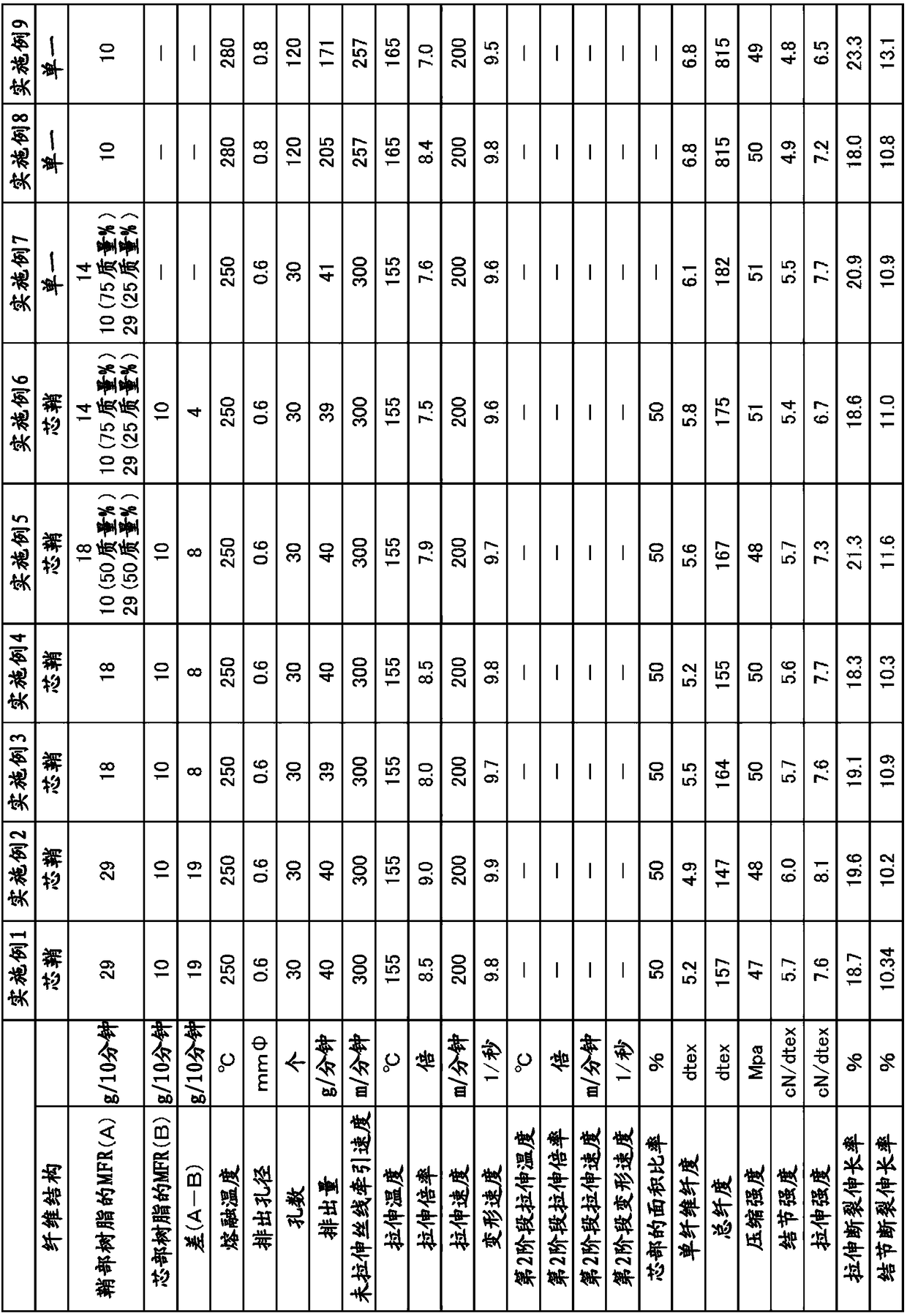

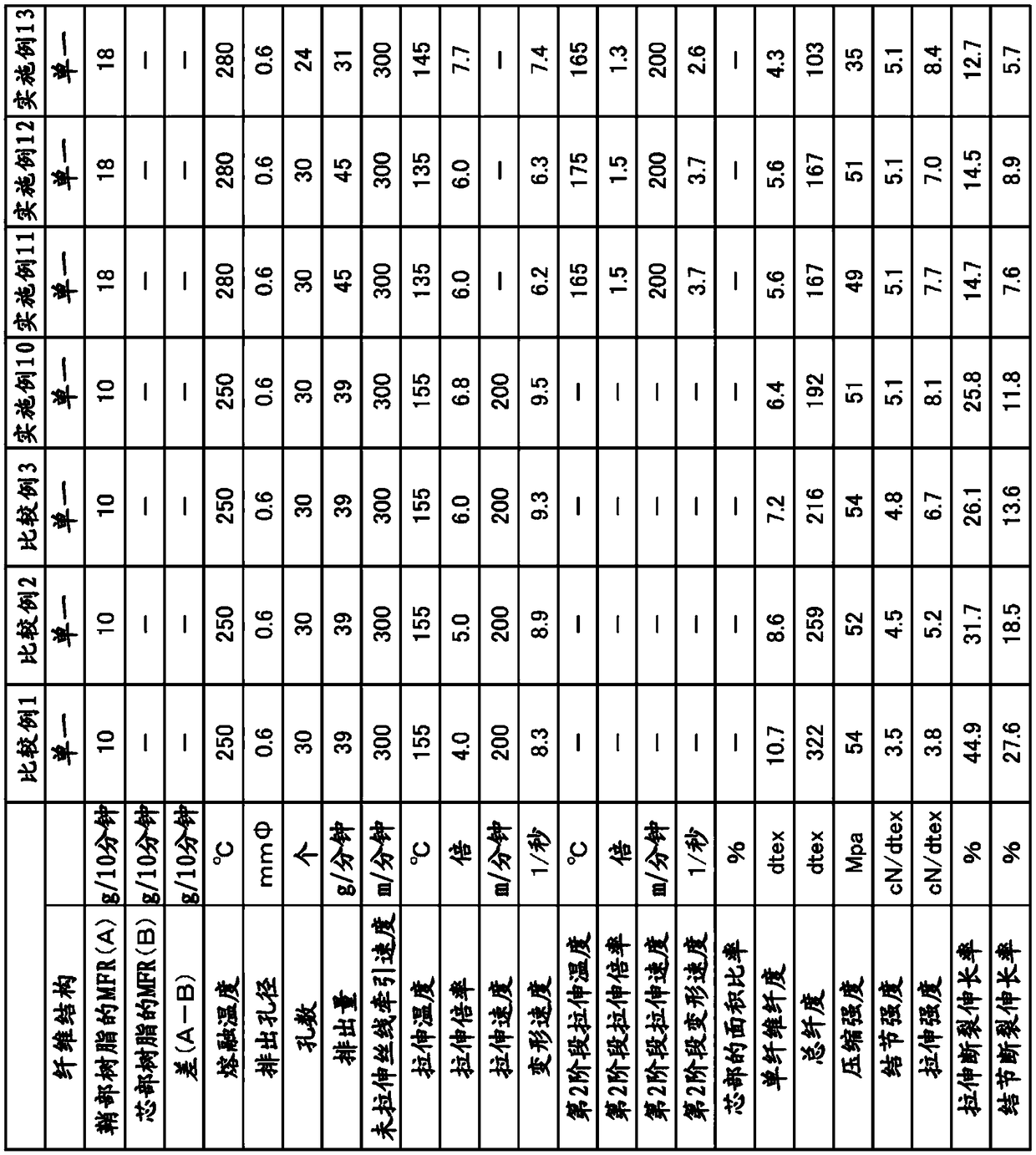

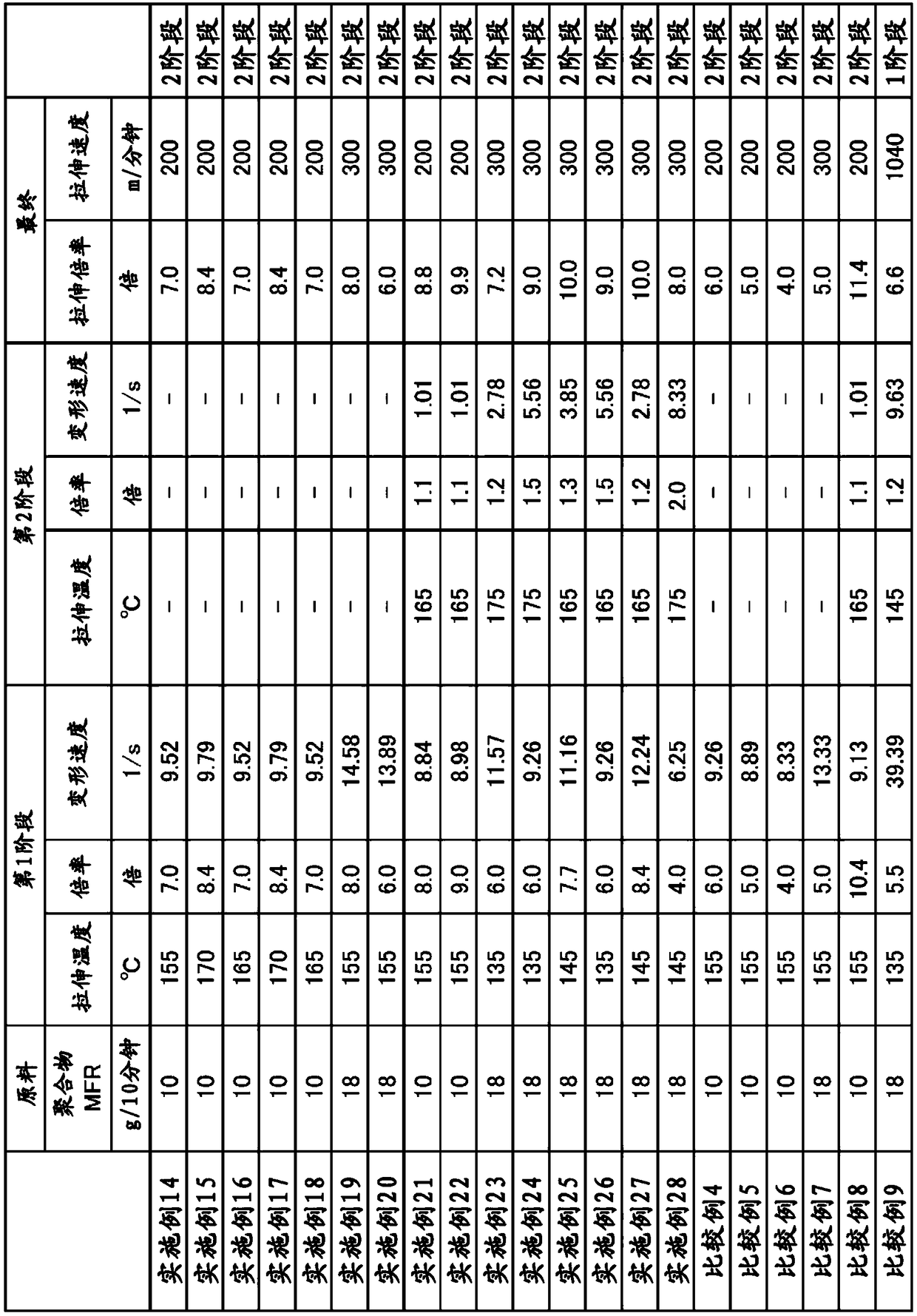

Embodiment 1

[0141] A polypropylene resin (Nippon Polypropylene Co., Ltd. SA01A, MFR=10 g / 10 minutes (230° C., load 2.16 kg, 10 minutes)) as a core was put into a kneader, and a polypropylene resin as a sheath ( SA03 manufactured by Nippon Polypropylene Co., Ltd., MFR=29g / 10 minutes (230°C, load 2.16kg, 10 minutes)) was put into a kneader different from the kneader of the core, heated to 250°C for melt kneading, Make the discharge aperture from The core-sheath composite fiber discharged from a core-sheath composite spinning nozzle with 30 discharge holes is contacted with cold air at 20°C to cool and solidify, then oil is applied, and it is wound on a bobbin at a pulling speed of 300m / min. In the core-sheath type composite fiber, the core portion accounted for 50% of the fiber weight in an undrawn yarn, and was discharged at a discharge rate of 40 g / min (1.33 g / min per hole).

[0142] The obtained undrawn yarn was preheated using a hot roll so that the yarn temperature became 70°C, and s...

Embodiment 2

[0144] Except having set the draw ratio to 9.0 times, it carried out similarly to Example 1, and obtained the polyolefin multifilament. Table 1 shows the physical properties of the obtained polypropylene resin multifilaments.

Embodiment 3

[0146] As the sheath, polypropylene resin (Y2000GV manufactured by Prime Polymer Co., Ltd., MFR=18g / 10 minutes (230° C., load 2.16 kg, 10 minutes)) was used, and the discharge rate was 39 g / min from the nozzle (1.30 g / min per hole). minutes) to obtain an unstretched yarn, except that the draw ratio was set to 8.0 times, and the polyolefin multifilament was obtained in the same manner as in Example 1. Table 1 shows the physical properties of the obtained polypropylene resin multifilaments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com