Mini-LED liquid crystal display backlight structure based on quantum dots and preparation method of mini-LED liquid crystal display backlight structure

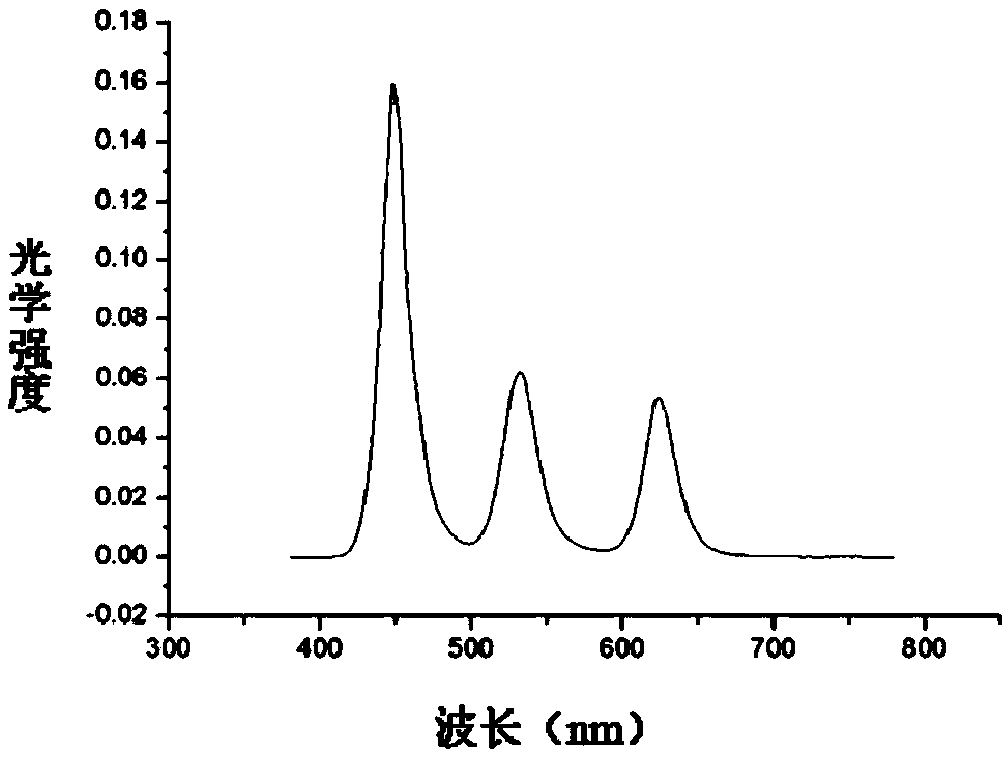

A liquid crystal display and backlight structure technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven brightness and color, fragility of electrodes and wires, large quantity, etc., and achieve simple preparation process, gentle lamination process, Effect of Narrow Emission Spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

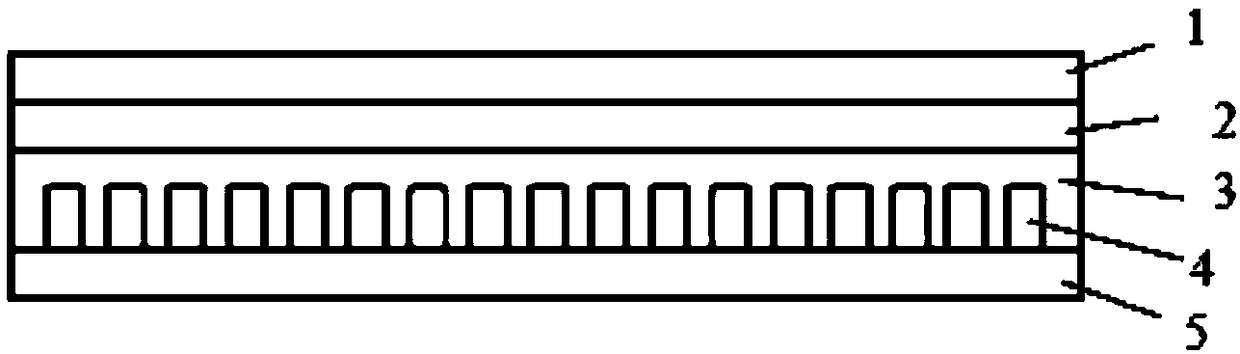

[0045] A quantum dot-based micro-LED liquid crystal display backlight structure, such as figure 2 shown. Prepared by:

[0046] (1) Fix the micro-LED blue-light chip on the substrate by welding to form a small-pitch micro-LED blue-light chip substrate;

[0047] (2) Spread the optical coating composition evenly on the substrate by coating, heat and cure at 110° C. for 10 minutes to form a quantum dot fluorescence conversion layer with a thickness of 100 μm;

[0048] (3) Evenly coat the bonding layer on the quantum dot fluorescence conversion layer, and cure and heat at 110°C for 5 minutes;

[0049] (4) Spread the adhesive evenly on the bonding layer by flow coating, heat and cure at 110°C for 10 minutes to form an adhesive layer, the thickness of which is higher than the height of the micro LED blue light chip;

[0050] (5) Bonding the adhesive layer to the micro-LED blue light chip substrate to form a micro-LED liquid crystal display backlight structure based on quantum dot...

Embodiment 2

[0053] A quantum dot-based micro-LED liquid crystal display backlight structure, such as Figure 4 As shown, the bottom of the micro-LED blue light chip substrate is a flat plate, and the surroundings extend upward to form a hollow structure, which has high reflectivity to the visible light band and is resistant to blue light radiation. Prepared by:

[0054] (1) Fix the micro-LED blue-light chip on the substrate by silica gel bonding to form the micro-LED blue-light chip substrate;

[0055] (2) Spread the optical coating composition evenly on the substrate by coating, and heat and cure at 110°C for 15 minutes to form a quantum dot fluorescence conversion layer with a thickness of 100 μm;

[0056] (3) Apply the bonding layer evenly on the quantum dot fluorescence conversion layer, and heat and cure at 110° C. for 5 minutes;

[0057] (4) Spread the adhesive evenly on the micro LED blue light chip substrate by flow coating, heat and cure at 50°C for 30 minutes to form an adhesi...

Embodiment 3

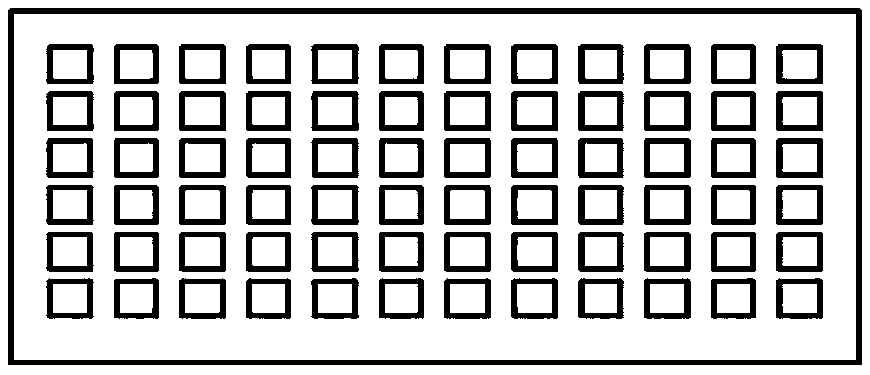

[0060] A quantum dot-based micro-LED liquid crystal display backlight structure, such as Figure 5 shown. The bottom of the micro-LED blue light chip substrate contains protrusion fillers, which are densely arranged in a grid form to form a large number of small cavity structures, and the micro LED blue light chips are fixed in the small cavities. The small cavity can further reflect blue light, enhance luminous efficiency, form a protective effect on the micro-LED chip, and at the same time have the function of high temperature resistance and prevent chip displacement. The material of the substrate is specially treated EMC or PC material. Prepared by:

[0061] (1) Fix the micro-LED blue-light chip on the substrate by silica gel bonding to form the micro-LED blue-light chip substrate;

[0062] (2) Spread the optical coating composition evenly on the substrate by coating, and heat and cure at 110°C for 15 minutes to form a quantum dot fluorescence conversion layer with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com