Method for smelting low phosphorus and sulfur steel with desulfurization and desiliconization of hot metal ladle and less converter slag

A technology for smelting with less slag and molten iron is applied in the fields of desulfurization and desilication of molten iron and smelting low-phosphorus-sulfur steel with less slag in a converter, which can solve the problems of long processing period, large iron loss and high cost investment, and achieves improved dephosphorization rate, The effect of improving the technical and economic indicators of steelmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

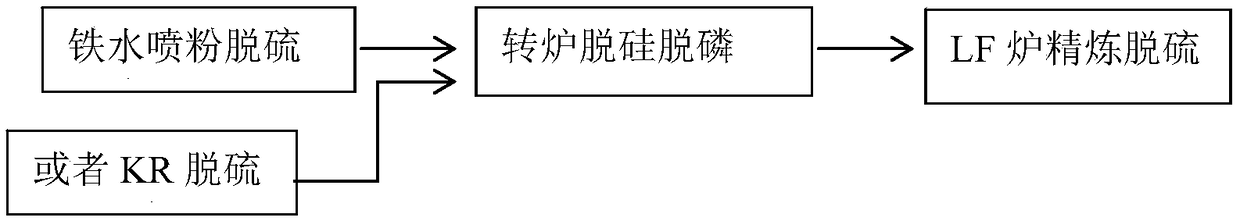

Method used

Image

Examples

Embodiment 1

[0077] This embodiment is carried out in the molten iron KR treatment station and converter, the molten iron is desulfurized and desiliconized in the molten iron tank, and decarburized, deep desiliconized and dephosphorized in the converter.

[0078] The parameters of the main equipment and raw materials of the KR processing station are as follows:

[0079] Inner height of molten iron treatment tank: 4120mm Diameter of bag mouth: 3100mm.

[0080] KR paddle paddle center column diameter: 500mm paddle length: 1050mm width: 830mm thickness: 370mm

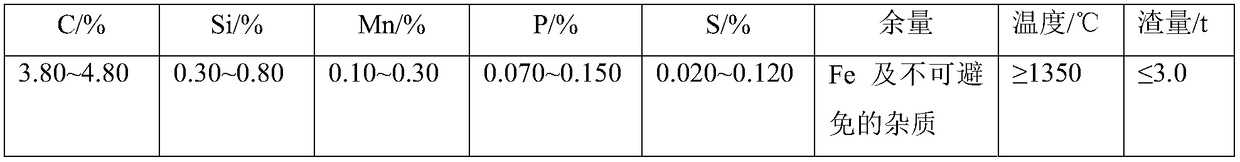

[0081] The composition of molten iron is shown in Table 11

[0082] Table 11

[0083] C / %

Si / %

Mn / %

P / %

S / %

temperature / ℃

Weight / t

Slag volume / t

4.20

0.45

0.25

0.130

0.045

1390℃

130

2.5

[0084] The composition of lime powder is shown in Table 12

[0085] Table 12

[0086] CaO / %

SiO 2 / %

MgO / %

P / %

S / %

Granularity / mesh

Moisture / %

...

Embodiment 2

[0114] The equipment and raw material parameters of the present embodiment and the KR described in embodiment 1 and the converter are the same.

[0115] The initial conditions of molten iron are shown in Table 18.

[0116] Table 18

[0117] C / %

Si / %

Mn / %

P / %

S / %

temperature / ℃

Weight / t

Slag volume / t

4.50

0.42

0.23

0.131

0.053

1402℃

137

2.3

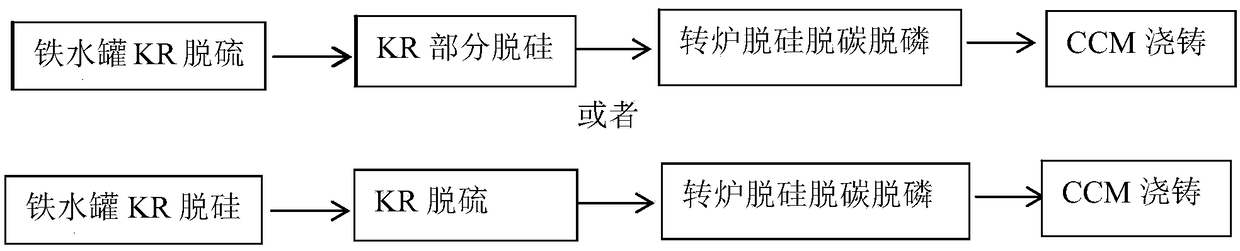

[0118] The process route of molten iron smelting into molten steel is: blast furnace molten iron—hot metal tank—a small amount of slag removal—KR desiliconization—slag removal—KR desulfurization—slag removal—adding scrap into converter—mixing low-silicon molten iron into converter—top-bottom blowing and decarburization Desiliconization and dephosphorization - converter tapping - ladle - continuous casting.

[0119] Process step 1: desiliconization of molten iron by KR method in the molten iron tank.

[0120] After the molten iron tank is opened to the KR treatment position...

Embodiment 3

[0127] The equipment and raw material parameters of the present embodiment and the KR described in embodiment 1 and the converter are the same.

[0128] The initial conditions of molten iron are shown in Table 18.

[0129] Table 18

[0130] C / %

Si / %

Mn / %

P / %

S / %

temperature / ℃

Weight / t

Slag volume / t

4.45

0.44

0.25

0.129

0.051

1410℃

135

2.1

[0131] The process route of molten iron smelting into molten steel is: blast furnace molten iron—hot metal tank—slag removal—KR desulfurization—slag removal—KR desiliconization—slag removal—adding scrap steel into converter—mixing low-silicon molten iron into converter—top-bottom blowing and decarburization Silicon dephosphorization - converter tapping - ladle - RH - continuous casting.

[0132] Process step 1: Desulfurization of molten iron by KR method in the molten iron tank.

[0133] Open the molten iron tank containing 135t of blast furnace molten iron to the KR treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com