Anti-ultraviolet thermosetting powder coating

A technology of thermosetting powder and UV resistance, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor stability of UV coatings, decreased UV resistance, and difficult photooxidation resistance, etc., to improve spraying processing Efficiency, shortened curing time, excellent salt spray resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

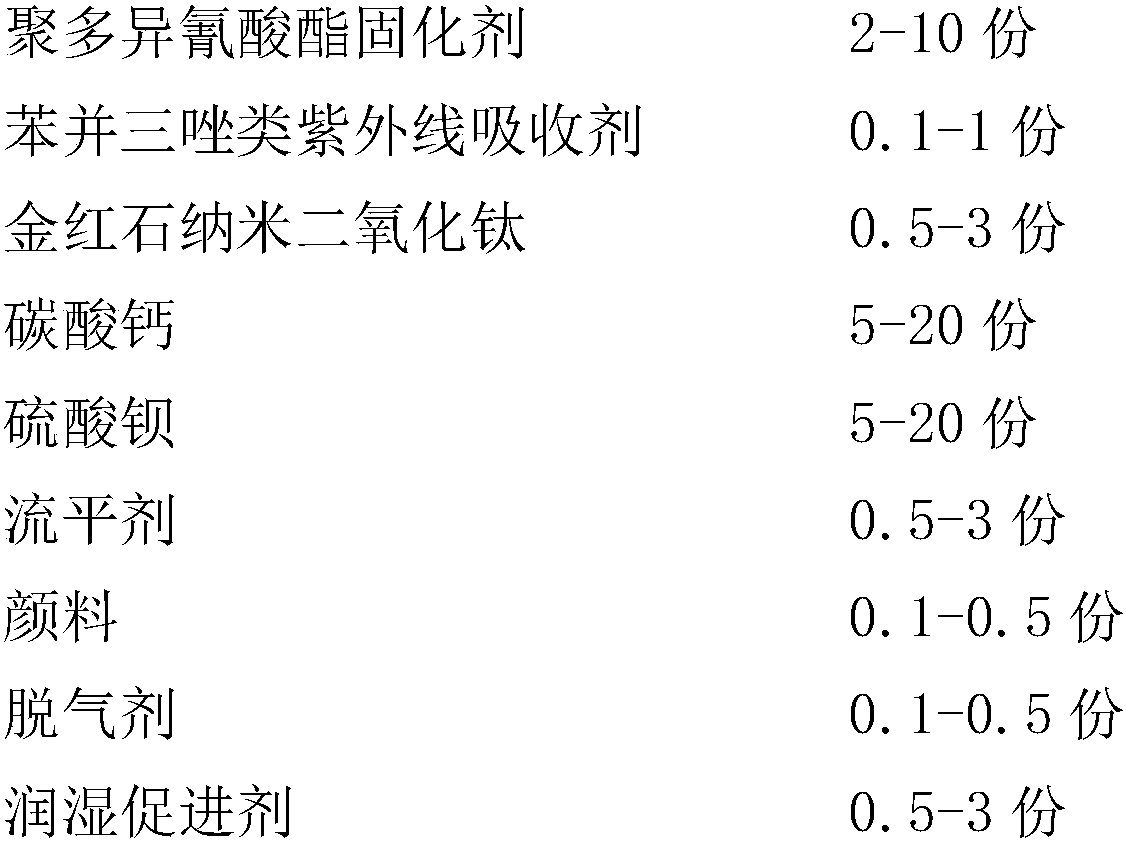

[0039] A thermosetting powder coating resistant to ultraviolet rays, which includes the following raw materials in parts by weight:

[0040]

[0041]

Embodiment 2

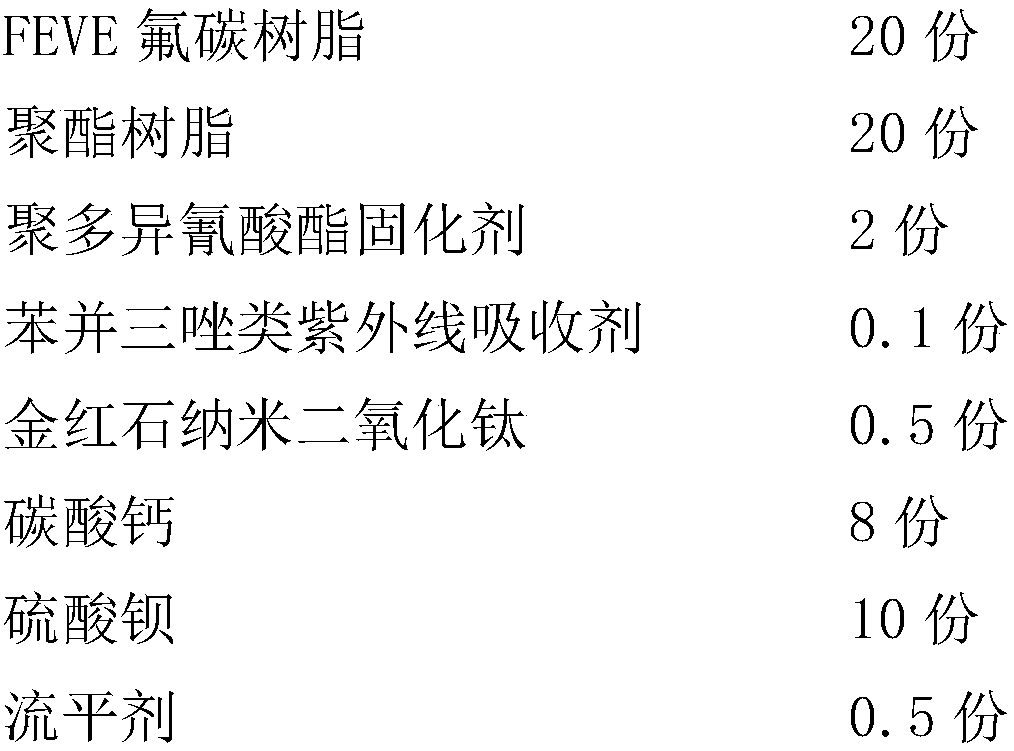

[0043]A thermosetting powder coating resistant to ultraviolet rays, which includes the following raw materials in parts by weight:

[0044]

Embodiment 3

[0046] A thermosetting powder coating resistant to ultraviolet rays, which includes the following raw materials in parts by weight:

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com