Preparation method and application of microorganism feed for milk thistle silybum marianum meal

A technology of microbial feed and silymarin meal, which is applied in the field of preparation of silymarin meal microbial feed, can solve the problems of low added value, poisoning of monogastric animals, activity discount of bacterial enzymes and functional substances, etc., and improve the overall nutritional level , promote the maturation of immune organs, and improve the effect of feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for milk thistle meal microbial feed, comprising the steps of:

[0034] (1) Phase I solid-state fermentation:

[0035] 1-A) Preparation of compound milk thistle meal mixture:

[0036] Prepare compound milk thistle meal by the ratio of 40% milk thistle meal, 25% vinegar residue, control water content is 35%; Add the cellulase of 20g / t in compound milk thistle meal (enzyme activity is 1 10,000 u / g), 20g / t xylanase (enzyme activity is 180,000 u / g), 5g / t mannanase (enzyme activity is 10,000 u / g), 30g / t α- Galactosidase (enzyme activity is 500u / g), 20g / t acid protease (enzyme activity is 60,000u / g), 20g / t β-glucanase (enzyme activity is 50,000u / g), The phytase of 20g / t (enzyme activity is 100,000 u / g) and the calcium hydrogen phosphate of 0.2% by mass are prepared into compound milk thistle meal mixture;

[0037] 1-B) Cultivation of mixed bacillus liquid strains:

[0038] Under sterile conditions, add a ring of Bacillus licheniformis, Bacillus subtil...

Embodiment 2

[0060] Other implementations are the same as in Example 1, except that the inoculum size of the mixed bacillus liquid strain in step 1-D) is 10%, acid protease (enzyme activity is 60,000 u / g) in step 1-A) The added amount is 200g / t.

Embodiment 3

[0062] Other implementations are the same as in Example 1, except that the addition of cellulase (enzyme activity is 10,000 u / g) in step 1-A) is 200g / t; xylanase (enzyme activity is 180,000 u / g) u / g) is added in an amount of 200g / t mannanase (enzyme activity is 10,000u / g) is added in an amount of 20g / t; α-galactosidase (enzyme activity is 500u / g) is added in an amount 300g / t; β-glucanase (enzyme activity: 50,000 u / g) added at 200g / t.

[0063] Finished product analysis:

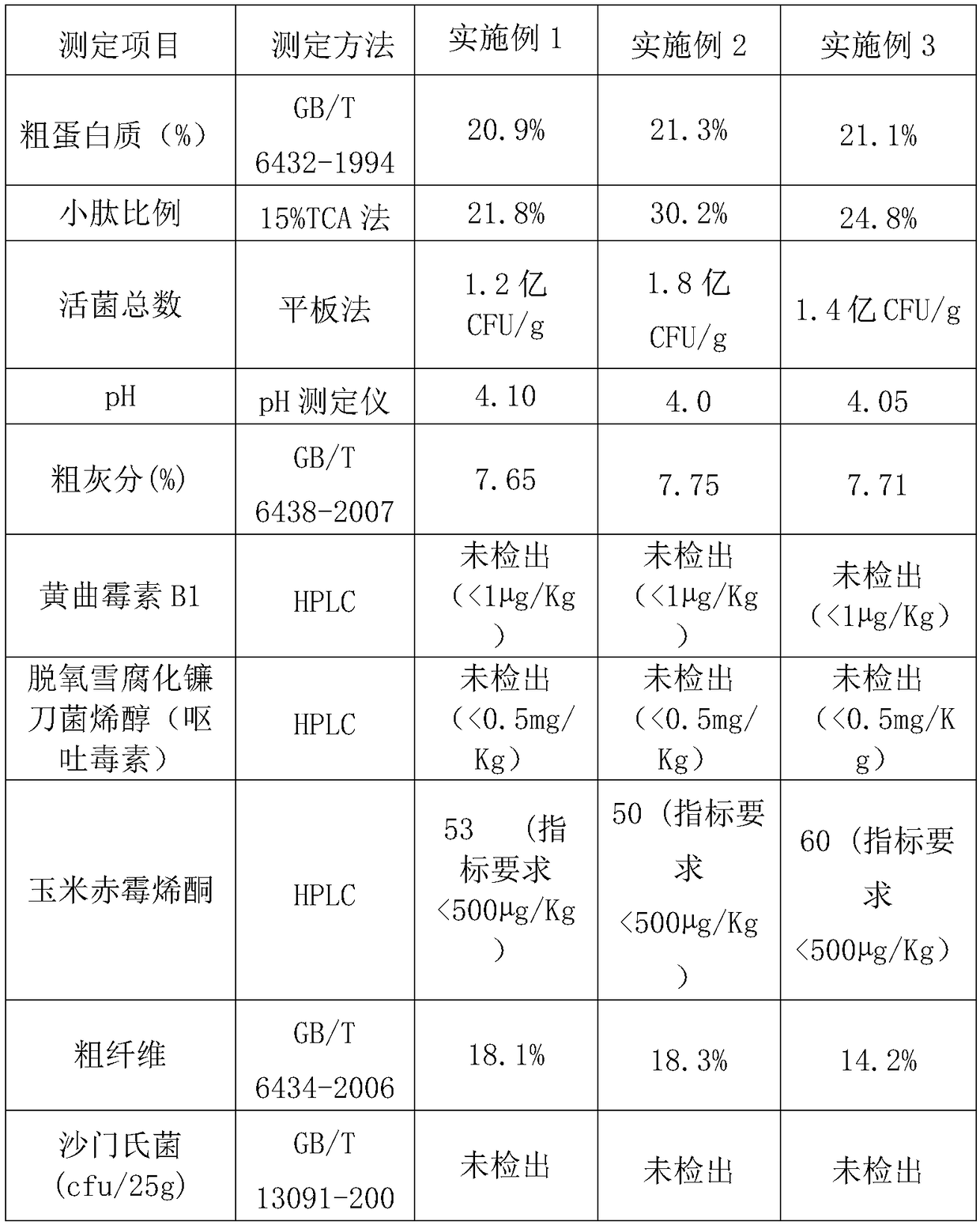

[0064] For embodiment 1-3 after the microbial feed finished product after two-stage anaerobic fermentation one month carries out sample detection, specifically as shown in table 1:

[0065] Table 1 Example 1-3 microbial feed finished product test

[0066]

[0067]

[0068] Result analysis:

[0069] As can be seen from Table 1, the acidity of a kind of milk thistle meal microbial feed prepared by Examples 1-3 of the present invention has dropped to 4.1 in terms of pH, which means that the quality has s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com