High-performance lithium ion battery composite cathode material and preparation method thereof

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as complicated and cumbersome methods, uneven surface coating of large particles, spontaneous aggregation of small particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1, prepare 400 mL of 0.5 mg / mL graphene ethanol solution, add 10 g of lithium iron phosphate, stir for 0.5 hours, ultrasonically disperse for 2 hours, stir for another 0.5 hours, ultrasonically disperse for 2 hours, and cycle 12 to 24 times; Step 2 , filter and dry the ultrasonically dispersed solution to obtain a composite material of graphene and lithium iron phosphate; step 3, put 88.8g of lithium nickel cobalt aluminate and 1.0g of polyvinylidene fluoride into a mixer and stir for 4~ 6 hours, the stirring speed is 1000rpm~2000rpm; step 4, put the composite material obtained in step 2 and the mixed powder in step 3 into a planetary ball mill, mix for 10~60min, and the ball milling speed is 100rpm~500rpm, and finally get High performance composite cathode material.

[0051] The SEM (scanning electron microscope) figure of the composite cathode material obtained by this embodiment is as follows figure 1 As shown, A is a composite material of graphene and lithium ...

Embodiment 2

[0056] Step 1, prepare 400 mL of 0.5 mg / mL graphene ethanol solution, add 10 g of lithium iron phosphate, stir for 0.5 hours, ultrasonically disperse for 2 hours, stir for another 0.5 hours, ultrasonically disperse for 2 hours, and cycle 12 to 24 times; Step 2 , filter and dry the ultrasonically dispersed solution to obtain a composite material of graphene and lithium iron phosphate; step 3, put 88.8g of nickel-cobalt lithium manganate and 1.0g of polyvinylidene fluoride into a mixer and stir for 4~ 6 hours, the stirring speed is 1000rpm~2000rpm; step 4, put the composite material obtained in step 2 and the mixed powder in step 3 into a planetary ball mill, mix for 10~60min, and the ball milling speed is 100rpm~500rpm, and finally get High performance composite cathode material.

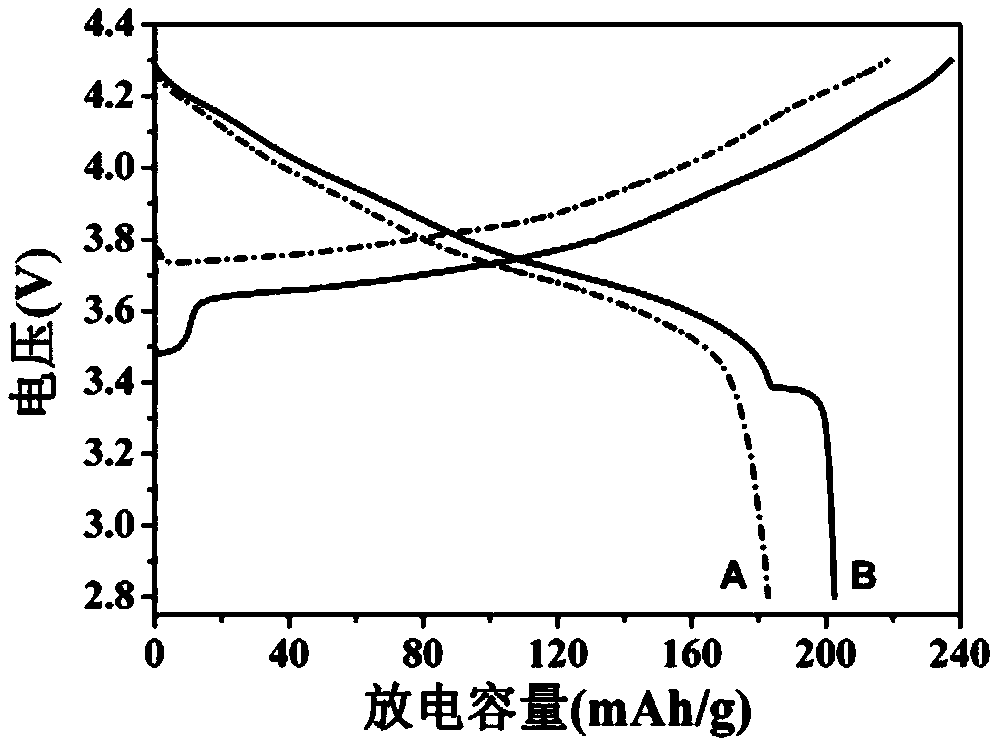

[0057] The rate performance curve of the composite positive electrode material obtained by this embodiment is as follows Figure 5 As shown, A is nickel-cobalt lithium manganate cathode material, an...

Embodiment 3

[0059] Step 1, prepare 400 mL of 1.0 mg / mL graphene ethanol solution, add 20 g of lithium iron phosphate, stir for 0.5 hours, ultrasonically disperse for 2 hours, after stirring for another 0.5 hours, ultrasonically disperse for 2 hours, and cycle 12 to 24 times; Step 2 , filter and dry the ultrasonically dispersed solution to obtain a composite material of graphene and lithium iron phosphate; step 3, put 78.8g of lithium nickel cobalt aluminate and 0.8g of polyvinylidene fluoride into a mixer and stir for 4~ 6 hours, the stirring speed is 1000rpm~2000rpm; step 4, put the composite material obtained in step 2 and the mixed powder in step 3 into a planetary ball mill, mix for 10~60min, and the ball milling speed is 100rpm~500rpm, and finally get High performance composite cathode material.

[0060] The differential thermal analysis (DSC) curve of the first week charge-discharge curve of the composite positive electrode material obtained by this embodiment after the first charge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com