Method for preparing ohmic contact electrode of P-type negative temperature coefficient ceramic material

An ohmic contact electrode, negative temperature coefficient technology, applied in the direction of resistors with negative temperature coefficient, resistance manufacturing, resistors with terminals, etc., can solve the problem of low contact resistance, to solve the problem of penetration, maintain flatness and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

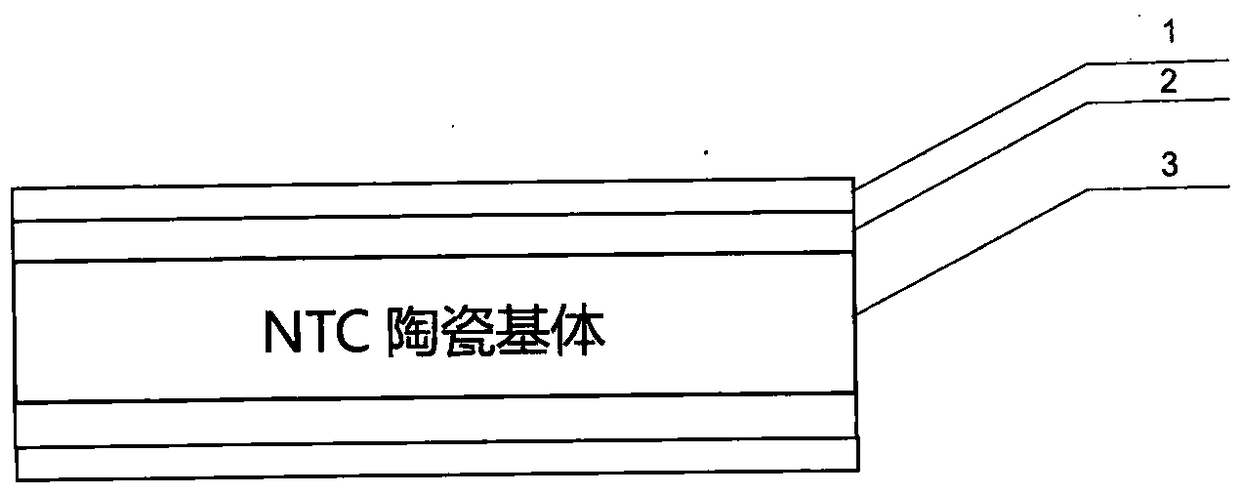

[0020] a. Select the existing quaternary system cobalt, manganese, iron and zinc P-type negative temperature coefficient ceramic materials as the ceramic substrate 3, then use alcohol and deionized water to ultrasonically clean the P-type negative temperature coefficient ceramic substrate 3 respectively, and clean The time is 30 minutes and 10 minutes respectively, and then the cleaned P-type negative temperature coefficient ceramic substrate 3 is put into an oven at a temperature of 100° C. for 30 minutes;

[0021] b. Cover the mask plate on the P-type negative temperature coefficient ceramic substrate 3 obtained in step a, and use DC magnetron sputtering to vapor-deposit a 35nm Pd transition layer 2 with a purity of 99.99% on the P-type negative temperature coefficient ceramic substrate 3 , and then vapor-deposit 400nm of Ag with a purity of 99.99% as the soldering layer 1, wherein the magnetron sputtering condition is that the background vacuum degree of the equipment is 1.5...

Embodiment 2

[0024] a. Select the existing quaternary system cobalt, manganese, iron and zinc P-type negative temperature coefficient ceramic materials as the ceramic substrate 3, then use alcohol and deionized water to ultrasonically clean the P-type negative temperature coefficient ceramic substrate 3 respectively, and clean The time is 30 minutes and 10 minutes respectively, and then the cleaned P-type negative temperature coefficient ceramic substrate 3 is put into an oven at a temperature of 100° C. for 30 minutes;

[0025] b. Cover the mask plate on the P-type negative temperature coefficient ceramic substrate 3 obtained in step a, and use DC magnetron sputtering to vapor-deposit a 70nm Ni transition layer 2 with a purity of 99.99% on the P-type negative temperature coefficient ceramic substrate 3 , and then vapor-deposit 400nm of Ag with a purity of 99.99% as the soldering layer 1, wherein the magnetron sputtering condition is that the background vacuum degree of the equipment is 1.5...

Embodiment 3

[0028] a. Select the existing quaternary system cobalt, manganese, iron and zinc P-type negative temperature coefficient ceramic materials as the ceramic substrate 3, then use alcohol and deionized water to ultrasonically clean the P-type negative temperature coefficient ceramic substrate 3 respectively, and clean The time is 30 minutes and 10 minutes respectively, and then the cleaned P-type negative temperature coefficient ceramic substrate 3 is put into an oven at a temperature of 100° C. for 30 minutes;

[0029] b. Cover the mask plate on the P-type negative temperature coefficient ceramic substrate 3 obtained in step a, and use DC magnetron sputtering to vapor-deposit a 100nm Pd transition layer 2 with a purity of 99.99% on the P-type negative temperature coefficient ceramic substrate 3 , and then vapor-deposit 400nm of Ag with a purity of 99.99% as the soldering layer 1, wherein the magnetron sputtering condition is that the background vacuum degree of the equipment is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com