Resistance-value smart grid deformation testing system and method based on ten-shaft sensor

A shaft sensor, deformation testing technology, applied in the direction of electric/magnetic solid deformation measurement, instruments, measuring devices, etc., can solve the damage of the internal area of small damage, which cannot be observed by the naked eye, the system data processing is not mature enough, and the model is prone to data deviation and other problems, to achieve the effect of saving field experiment time, saving manpower, material and financial resources, and being beneficial to engineering safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

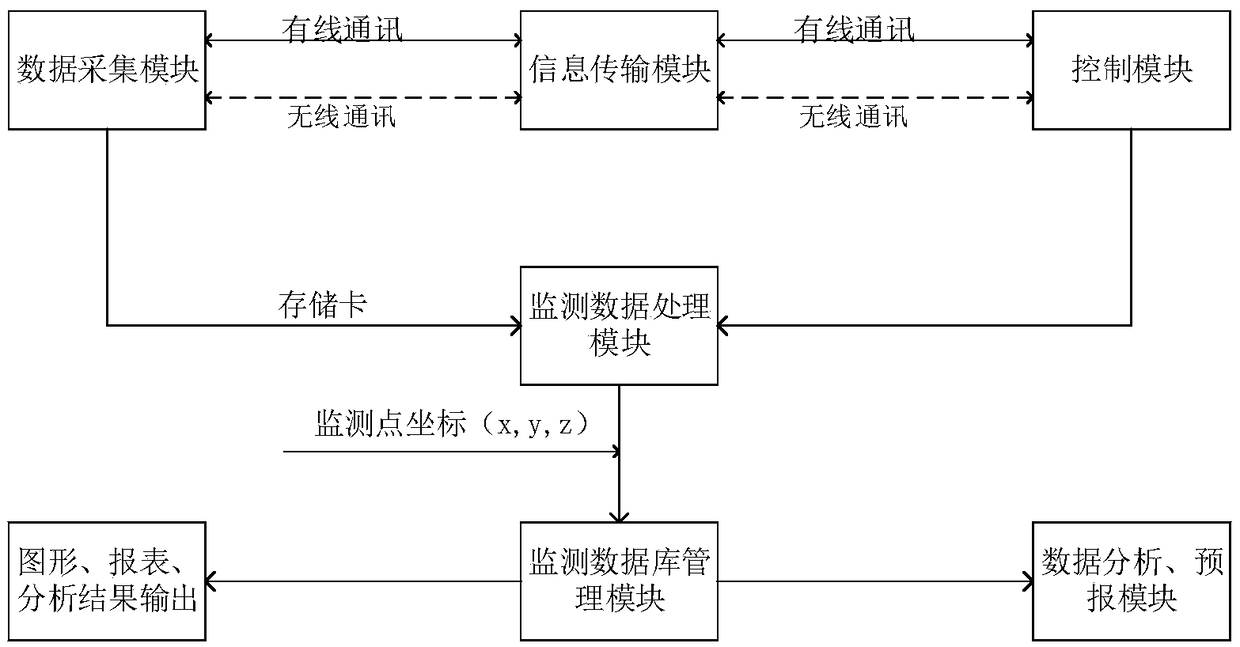

[0073] Such as figure 1 As shown, it is a schematic diagram of the structural framework of the present disclosure; the resistance smart grid deformation test system based on the ten-axis sensor includes: a data acquisition module, an information transmission module, a control module, a monitoring data processing module, a monitoring data management module, and a data analysis module. Prediction module and mobile server.

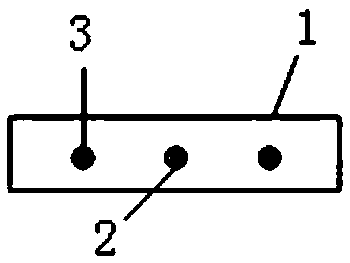

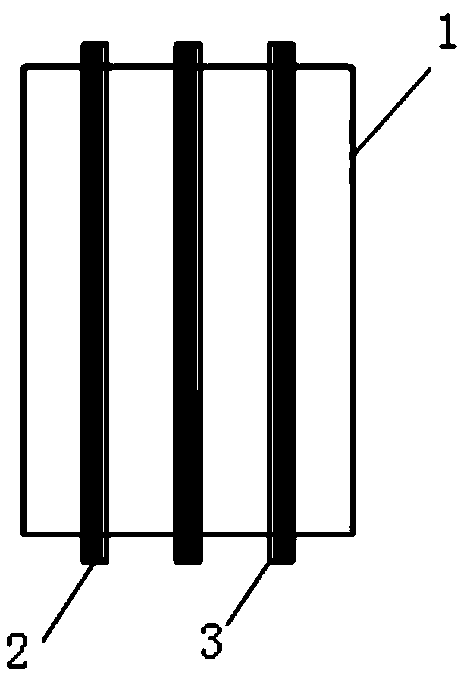

[0074] The data acquisition module includes: resistance smart grid and ten-axis sensor resistance smart grid;

[0075] The resistance smart grid and the ten-axis sensor resistance smart grid respectively transmit the collected data to the control module and the monitoring data processing module through the information transmission module to further process the collected data;

[0076] The control module performs data interaction with the monitoring data processing module through the information transmission module;

[0077] One end of the monitoring data ma...

Embodiment 2

[0125] The method of using the resistance smart grid deformation testing system based on the ten-axis sensor includes the following steps:

[0126] The ten-axis sensor chip embedded in the ten-axis sensor resistance smart grid can collect the data information of the monitoring point acceleration, angle, angular velocity, magnetic field, altitude, air pressure and geographical coordinates; the resistance smart grid and the ten-axis sensor resistance smart grid The metal wire embedded in the geogrid deforms with the geogrid, resulting in a corresponding change in the resistance value, which is converted into data information of voltage or current changes through the conversion circuit;

[0127] After the monitoring data processing module obtains the data information collected in real time by the resistance smart grid and the resistance smart grid of the ten-axis sensor at the monitoring point, it analyzes and processes the collected data information to obtain the deformation situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com