Gas pipe alloy of domestic gas stove, preparation method of gas pipe alloy and gas pipe

A technology for gas pipes and gas stoves, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of easy cavitation, poor wear resistance, shortened service life of gas pipes, etc. Good wear resistance and the effect of grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

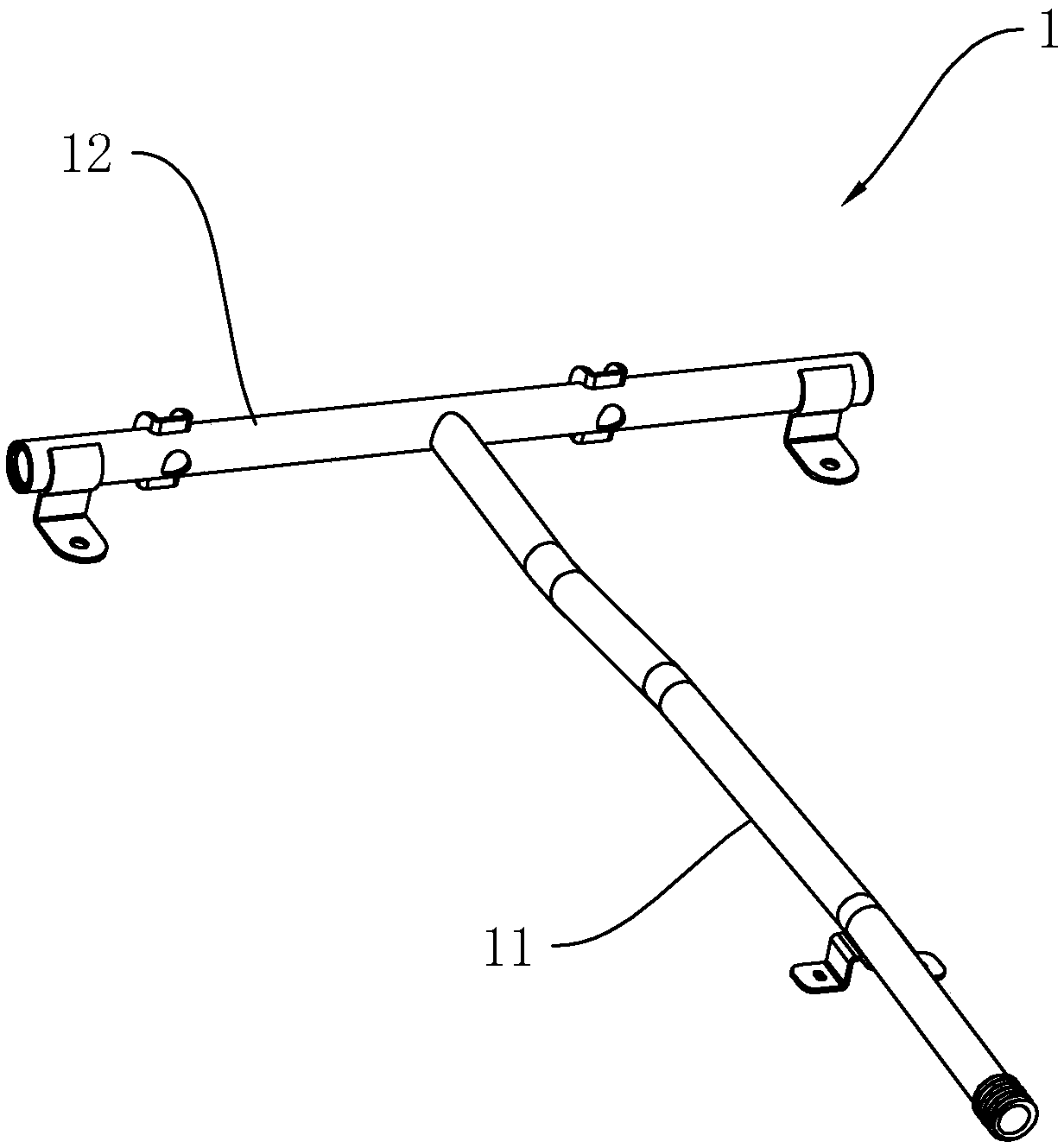

Image

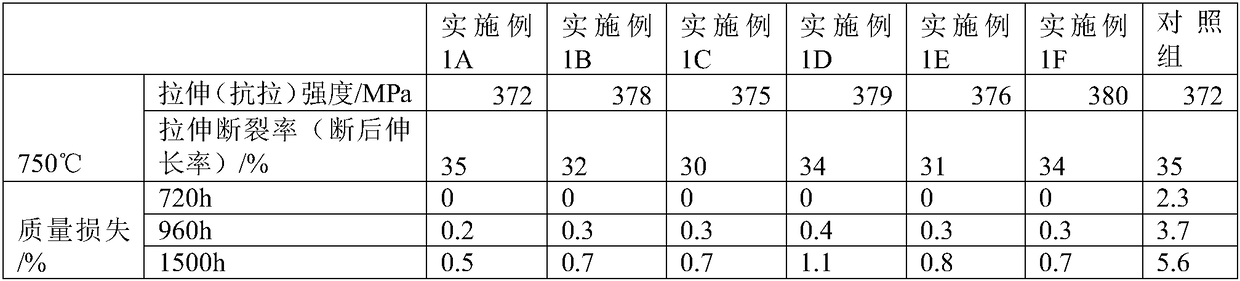

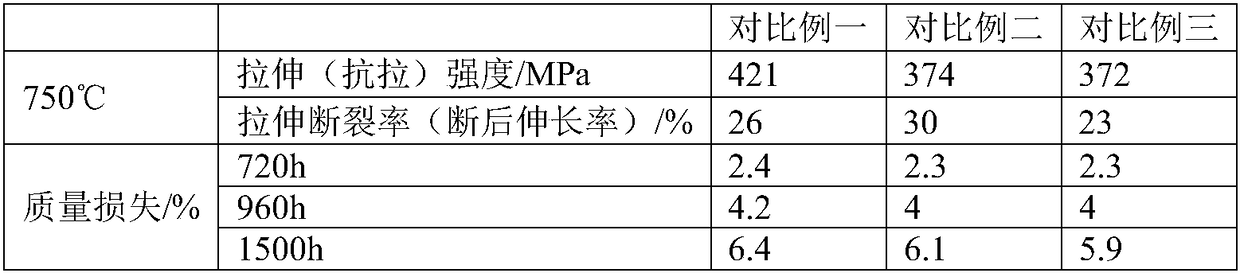

Examples

Embodiment 1

[0051] A household gas stove gas pipe alloy, its composition by mass fraction is:

[0052] C: 1.95-2.01wt%, Si: 0.17-0.20wt%, Mn: 0.30-0.60wt%, P: 0.001-0.01wt%, S: 0.001-0.012wt%, Cr: 0.20-0.25wt%, V: 0.56-0.62wt%, Al: 5.5-5.8wt%, Pb: 0.12-0.17wt%, Ti: 0.13-0.18wt%, Co: 0.12-0.17wt%, Y: 0.2-0.25wt%, Fe: 90.61- 91.01wt%, other alloy metal elements: 0.5-0.67wt%, and the rest are unavoidable impurities.

[0053] The addition method of Al is Al 4 C 3 . The Si addition method includes SiC, and Si in SiC accounts for 85-90% of the Si mass content in the obtained alloy. Unavoidable impurities include [H], and the mass fraction of [H] is 0.0002-0.00025wt%.

[0054] The preparation method of the above-mentioned domestic gas stove gas pipe alloy comprises the following steps:

[0055] S1: Put molten iron and steel scrap into the converter, carry out conventional top-bottom combined blowing to control blowing oxygen pressure 0.8-0.82MPa, when the tapping temperature is 1620-1640°C...

Embodiment 2

[0081] A gas pipe, based on Example 1A, the difference is that in S4, ferrosilicon alloy is used instead of SiC, and the Si composition is adjusted to be qualified.

Embodiment 3

[0083]A gas pipe, based on Example 1A, the difference is that cobalt-iron alloy is not added in the preparation method of household gas stove gas pipe alloy, titanium-iron alloy is replaced by pig iron, and the original Ti and Co components are replaced by Fe content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com