A kind of rare earth microalloyed bearing steel and its preparation method

A technology of microalloying and bearing steel, which is applied in the field of bearing steel manufacturing, can solve the problems that the high-end bearing industry is difficult to support industrial transformation and upgrading, and achieve the effect of improving product purity, good dimensional stability, and meeting mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] A rare-earth micro-alloyed bearing steel, the rare-earth micro-alloyed bearing steel comprises the following components: carbon content of 0.95-1.05 wt%, silicon content of 0.15-0.35 wt%, manganese content of 0.25-0.45 wt% , the chromium content is 1.45-1.60wt%, the nickel content is 0.05-0.09wt%, the molybdenum content is 0.02-0.05wt%, the aluminum content is 0.010-0.050wt%, the copper content is 0.06-0.08wt%, and the niobium content is 0.010 ~0.045wt%; phosphorus content is less than 0.01wt%, sulfur content is less than 0.008wt%, yttrium content is less than 0.015wt%, cerium content is less than 0.008wt%, titanium content is less than 0.0020wt%, oxygen content is less than 0.002wt%, arsenic content is less than 0.040wt%, tin content is less than 0.030wt%, antimony content is less than 0.005wt%, lead content is less than 0.002wt%, calcium content is less than 0.001wt%, and the rest is iron.

[0039] A kind of rare earth microalloyed bearing steel described in this embo...

specific Embodiment approach 2

[0062] According to the preparation method of a rare earth microalloyed bearing steel described in the first embodiment, the method comprises the following steps:

[0063] Step 1, converter, LF-RH refining, billet continuous casting, after peeling the obtained continuous casting billet, stand by;

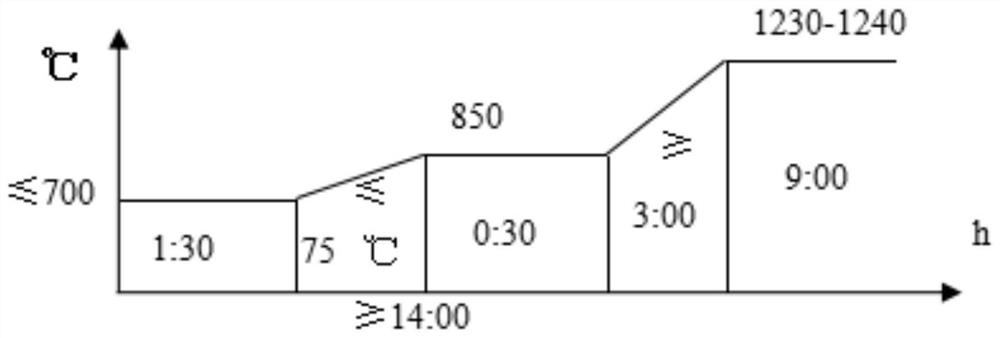

[0064] Step 2: Carry out electroslag remelting to the continuous casting slab obtained in step 1, then carry out cover cooling or pit cooling, and then carry out heating and rolling to open the billet once, after annealing or slow cooling, check and clean up to obtain a rolled billet, ready for use;

[0065] Step 3. Carrying out secondary heating and rolling of the primary rolling steel billet obtained in step 2, and after stack cooling or slow cooling, the secondary rolling steel billet is prepared for use;

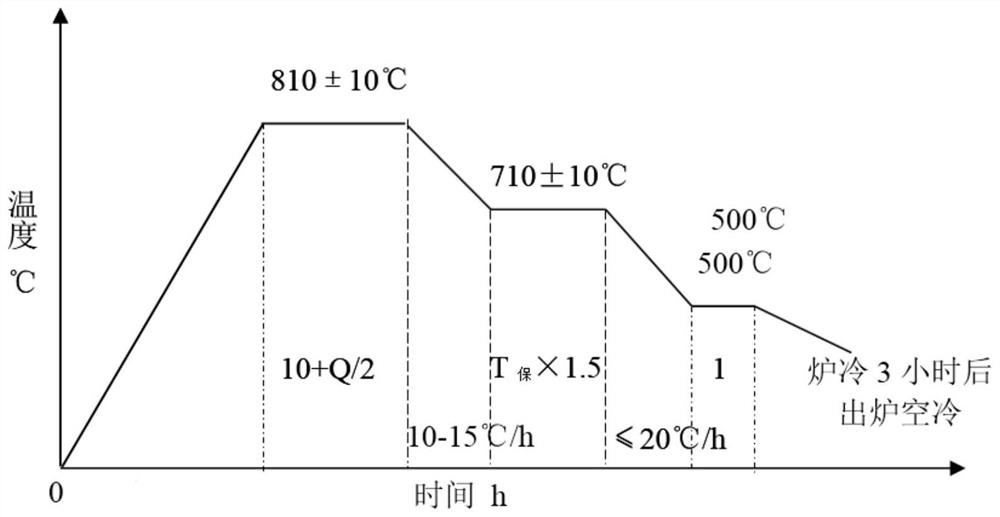

[0066] Step 4. Spheroidizing and annealing the secondary rolling steel slab obtained in step 3, straightening, polishing or peeling, flaw detection, cleaning and inspection, ...

specific Embodiment approach 3

[0068] According to the preparation method of a rare earth microalloyed bearing steel described in the second specific embodiment, in step 2, the electroslag remelting is smelted using purified slag smelting, the purified slag smelting process uses a Ф480*520 crystallizer, and the electrode uses grade steel. 250kg fluorite per furnace; metal electrode arc ignition, arc ignition current 0-4KA, refining current 5-6KA, refining time 30 minutes; smelting current 9.5-11KA, slag adding time 40 minutes, adding slag every 2 minutes Aluminum pellets 1.5Kg, 20 batches in total; Refining for 10 minutes after adding aluminum pellets and shutting down the furnace.

[0069] In the preparation method of a rare earth microalloyed bearing steel described in this embodiment, the electroslag remelting in step 2 adopts a quaternary slag system, and the ratio of the slag system is purified calcium fluoride, aluminum oxide, calcium oxide, The mass ratio of magnesium oxide is 27:40:18:5, and the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com