Preparation of layered double hydroxide/graphene oxide (LDH/GO) hybrid material and application of hydrotalcite/graphene oxide hybrid material in coatings

A hydrotalcite and graphite technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of limitation, difficulty in wide application, damage to graphene's long-term corrosion resistance, etc., and achieve the effect of low cost and simple and feasible preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

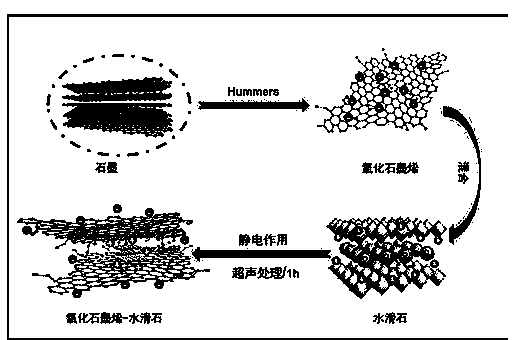

[0041] The preparation of a hydrotalcite / graphene oxide hybrid material and the application in the coating include the following steps.

[0042] (1) Phosphate intercalated hydrotalcite (PO 4 3- - Preparation of LDH).

[0043] 0.02mol (6.22g) of sodium phosphate dodecahydrate and 0.06mol (2.4g) of NaOH were dissolved in a beaker filled with 50ml of deionized water; subsequently 0.02mol (5.14g) of magnesium nitrate hexahydrate and 0.01mol ( 3.74g) of aluminum nitrate nonahydrate was dissolved in another beaker filled with 100ml deionized water; the above two solutions were added dropwise to the three-necked flask simultaneously, and the pH value was adjusted to be about 9-10; then, the mixed solution Reaction at 90°C in N2 atmosphere for 24 hours, the stirring rate is 100-200r / min; the resulting suspension is aged at room temperature for 12 hours; finally, the solution is washed with deionized water until neutral, filtered, and dried at 80°C Stand-by; the deionized water used...

Embodiment 2

[0055] (1) Phosphate intercalated hydrotalcite (PO 4 3- - Preparation of LDH).

[0056] 0.02mol (6.22g) of sodium phosphate dodecahydrate and 0.06mol (2.4g) of NaOH were dissolved in a beaker filled with 50ml of deionized water; subsequently 0.02mol (5.14g) of magnesium nitrate hexahydrate and 0.01mol ( 3.74g) of aluminum nitrate nonahydrate was dissolved in another beaker filled with 100ml deionized water; the above two solutions were added dropwise to the three-necked flask simultaneously, and the pH value was adjusted to be about 9-10; then, the mixed solution in N 2 Add to 90°C in the atmosphere and react for 24 hours, the stirring rate is 100-200r / min; the obtained suspension is aged at room temperature for 12 hours; finally, the solution is washed with deionized water until neutral, filtered, and dried at 80°C for use ; The deionized water used in the whole preparation process needs to remove CO 2 .

[0057] (2)PO 4 3- - Preparation of LDH dispersions.

[0058] W...

Embodiment 3

[0064] (1) Preparation of GO dispersion.

[0065] GO and deionized water were mixed according to a certain mass-volume ratio, and ultrasonically oscillated for 0.5-1 h to obtain a GO aqueous dispersion with a solution concentration of 3 mg / mL.

[0066] (2) Preparation of water-based coating base material.

[0067] Mix the water-based epoxy resin and the epoxy curing agent in a mass ratio of 2:1 and stir evenly to obtain a water-based epoxy resin slurry.

[0068] (3) Preparation of GO nanometer waterborne epoxy composite coating.

[0069] Mix the GO nano-dispersion liquid obtained in step (1) with the water-based coating base material obtained in step (2), stir slowly to form a uniformly dispersed slurry, and spray the uniformly dispersed slurry on the polished steel by high pressure On the chip, cure at room temperature for 3-5 days to obtain a GO nano water-based epoxy composite coating; the stirring speed is 50-70r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com