Packaging box and single-sheet packaging box prefabricating material and forming method and system thereof

A molding method and packaging box technology, applied in the field of liquid food packaging, can solve the problems of increased printing difficulty, easy falling off, affecting product quality, etc., and achieve the effect of improving the yield of finished products, meeting filling requirements, and avoiding the increase in printing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

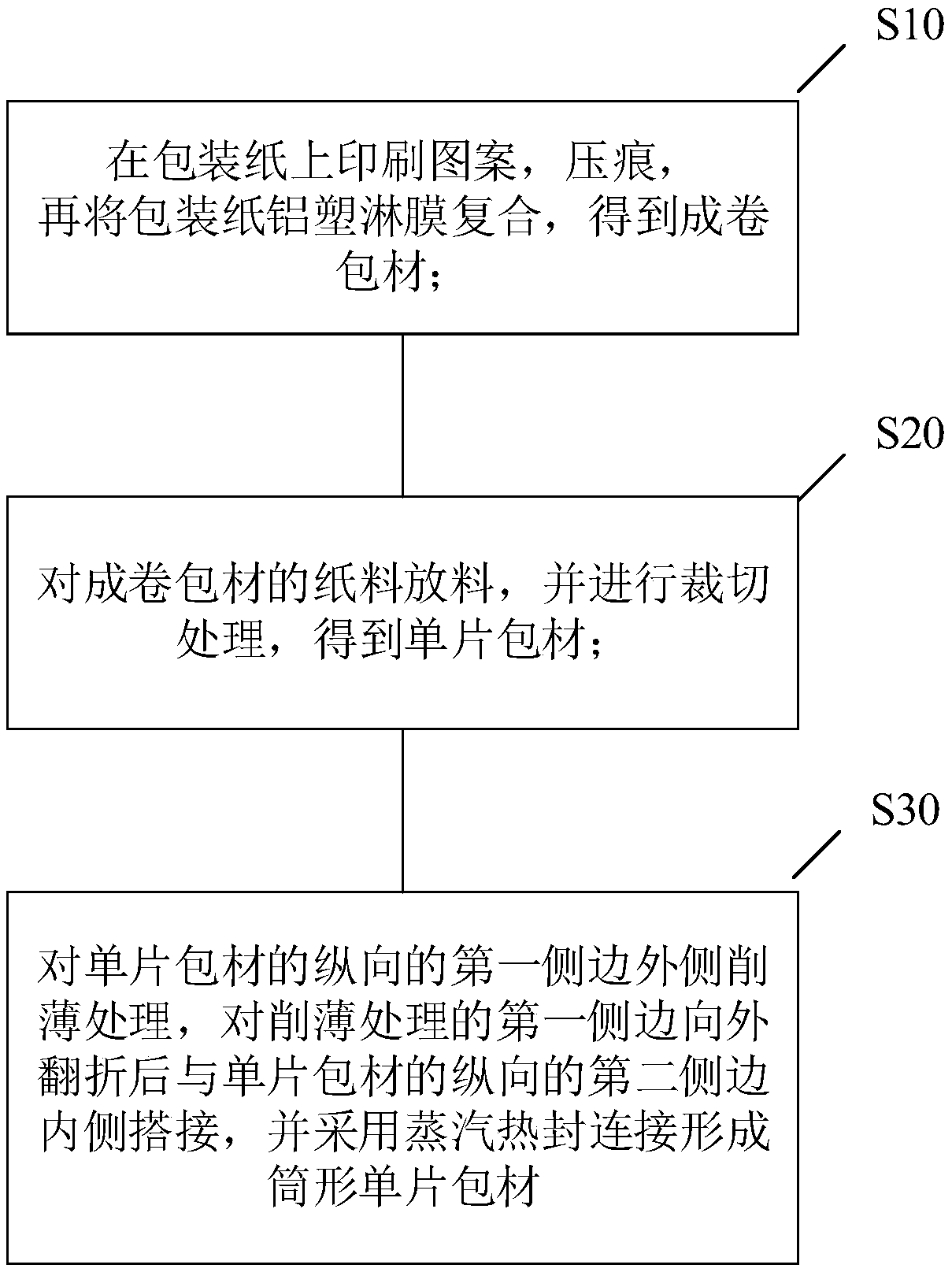

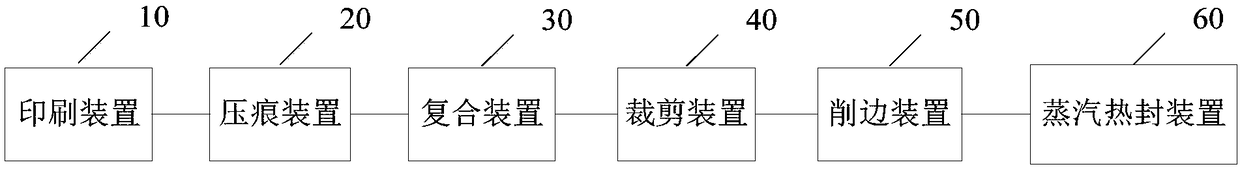

[0023] Such as figure 1 As shown, the present invention provides a method for forming a prefabricated material of a single-piece packaging box. The method includes the following steps: Step S10: printing patterns on the packaging paper, indenting, and then laminating the packaging paper with aluminum and plastic to obtain a finished product. roll packaging material; step S20: discharge the paper material of the roll packaging material, and perform cutting processing to obtain a single-piece packaging material; step S30: thin the outer side of the first vertical side of the single-piece packaging material, The thinned first side is folded outwards and overlapped with the inner side of the second longitudinal side of the single-piece pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com