Manufacturing method of graphene heating tube pressurized hot water equipment, hot water equipment, and air coating equipment

A technology of olefin heating pipe and hot water equipment, applied in the field of hot water heating equipment, can solve the problems of low thermal energy conversion efficiency and high energy consumption of hot water heating equipment, achieve good heating effect, improve heat exchange efficiency, and realize leakage protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

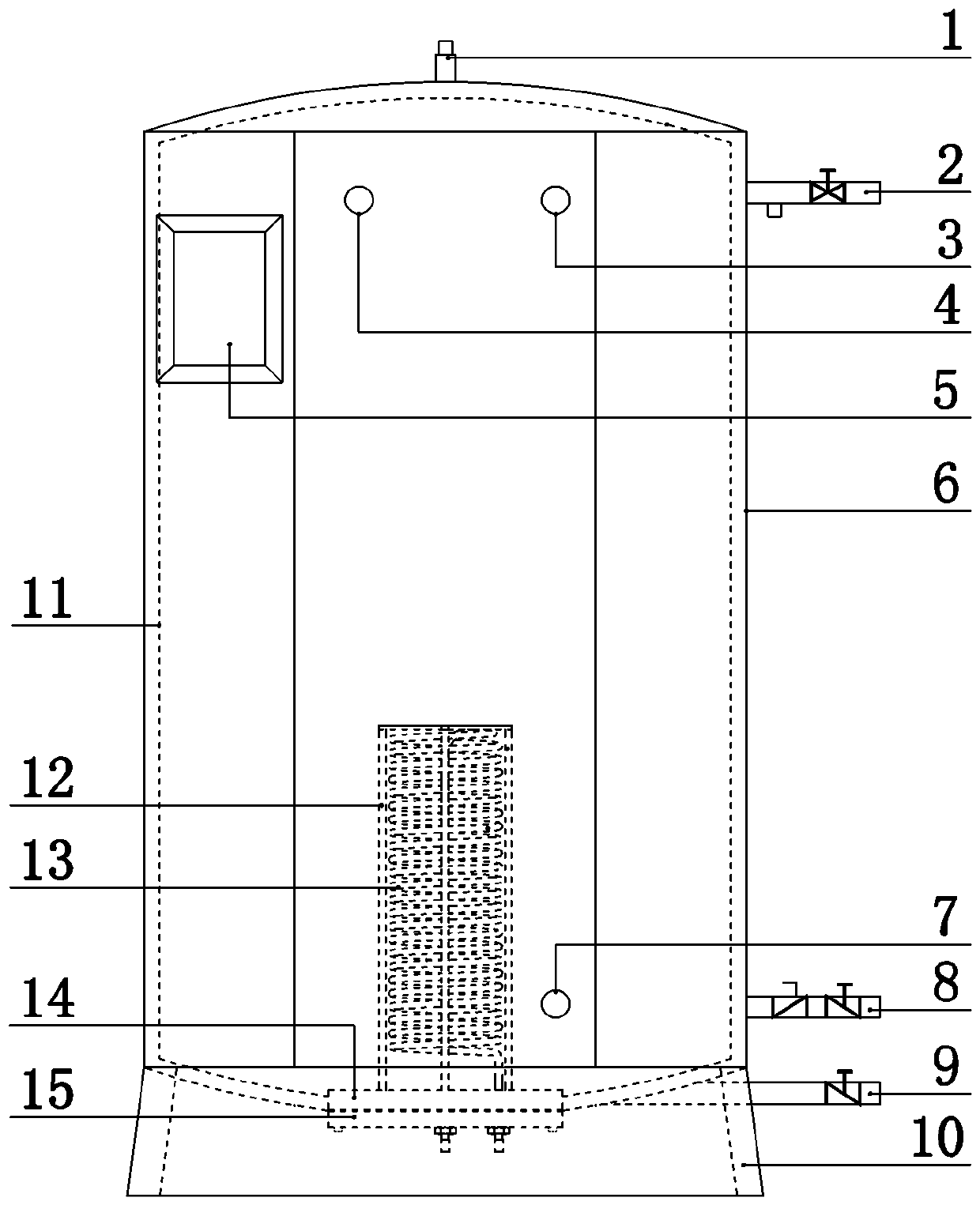

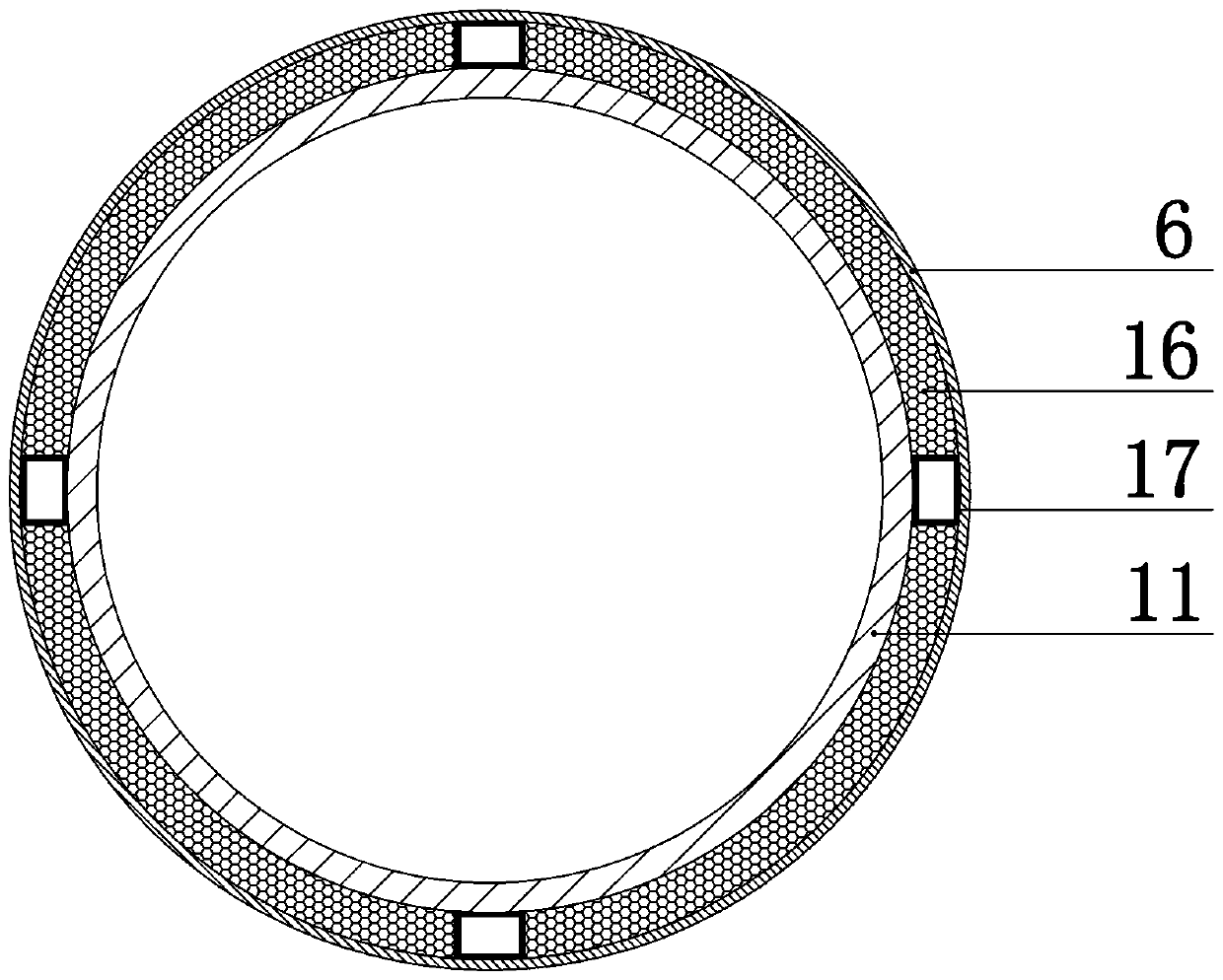

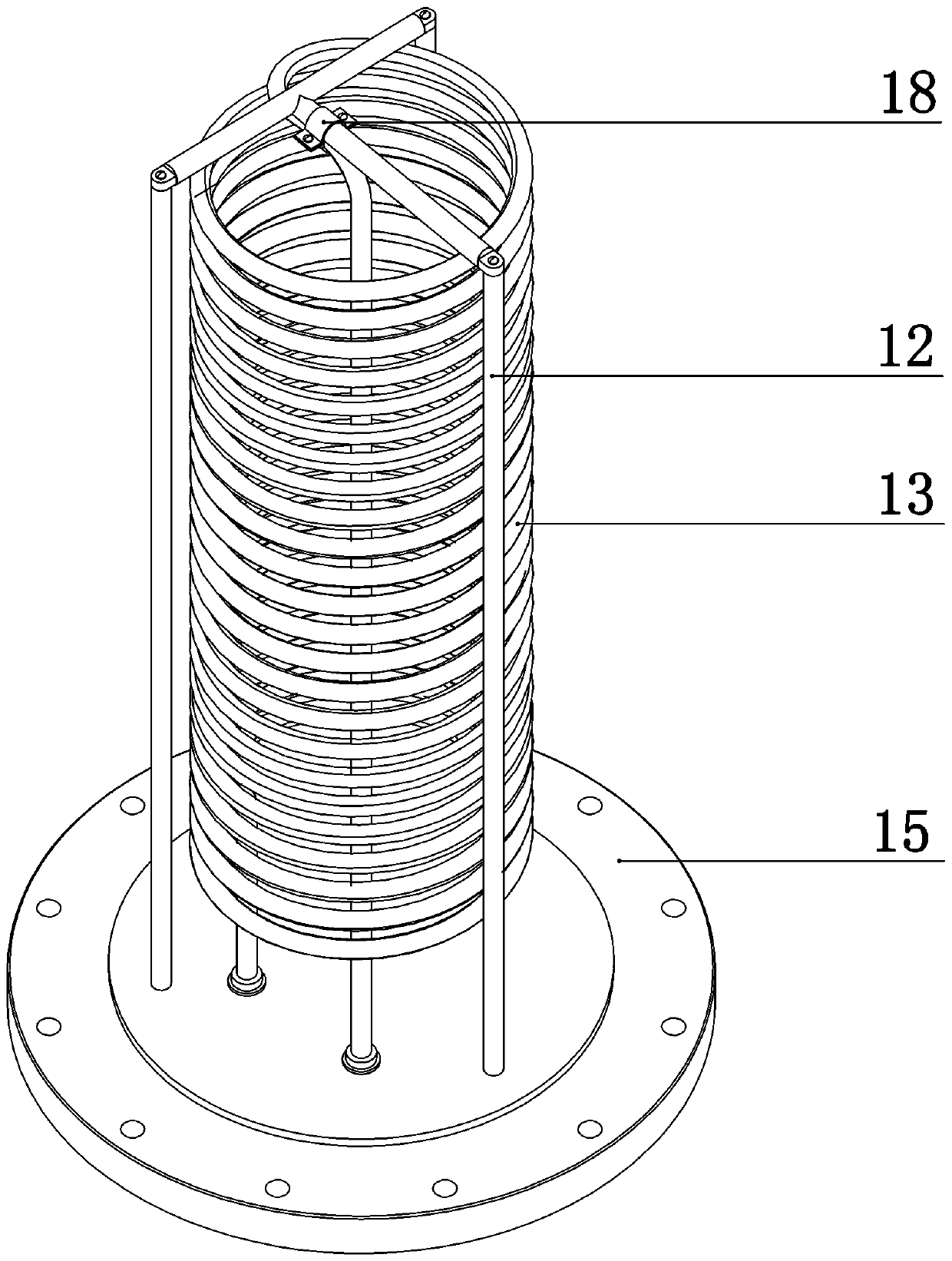

[0034] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0035] A method for manufacturing a graphene heating tube pressurized hot water device, comprising the following steps:

[0036](1) A stainless steel plate is used to round and weld the inner cylinder of the water tank, and the upper and lower ends are sealed and welded to the upper inner sealing plate and the lower inner sealing plate respectively; an installation hole is opened on the lower sealing plate, and a fixed flange is welded; The sewage joint, water inlet joint, water outlet joint and exhaust joint are welded on the side wall of the cylinder body in the water tank, and the inlet water temperature detection connection port, the water outlet temperature detection connection port and the water shortage protection connection port are set up.

[0037] (2) The outer cylinder of the water tank is formed by round welding of stainless steel plates, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com