Protection method of lithium ion battery electrode

A lithium-ion battery and electrode technology, applied in the repair/maintenance of secondary batteries, secondary batteries, circuits, etc., can solve the problems of affecting the electrical performance of batteries, hindering ion transport and transmission, and uneven film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

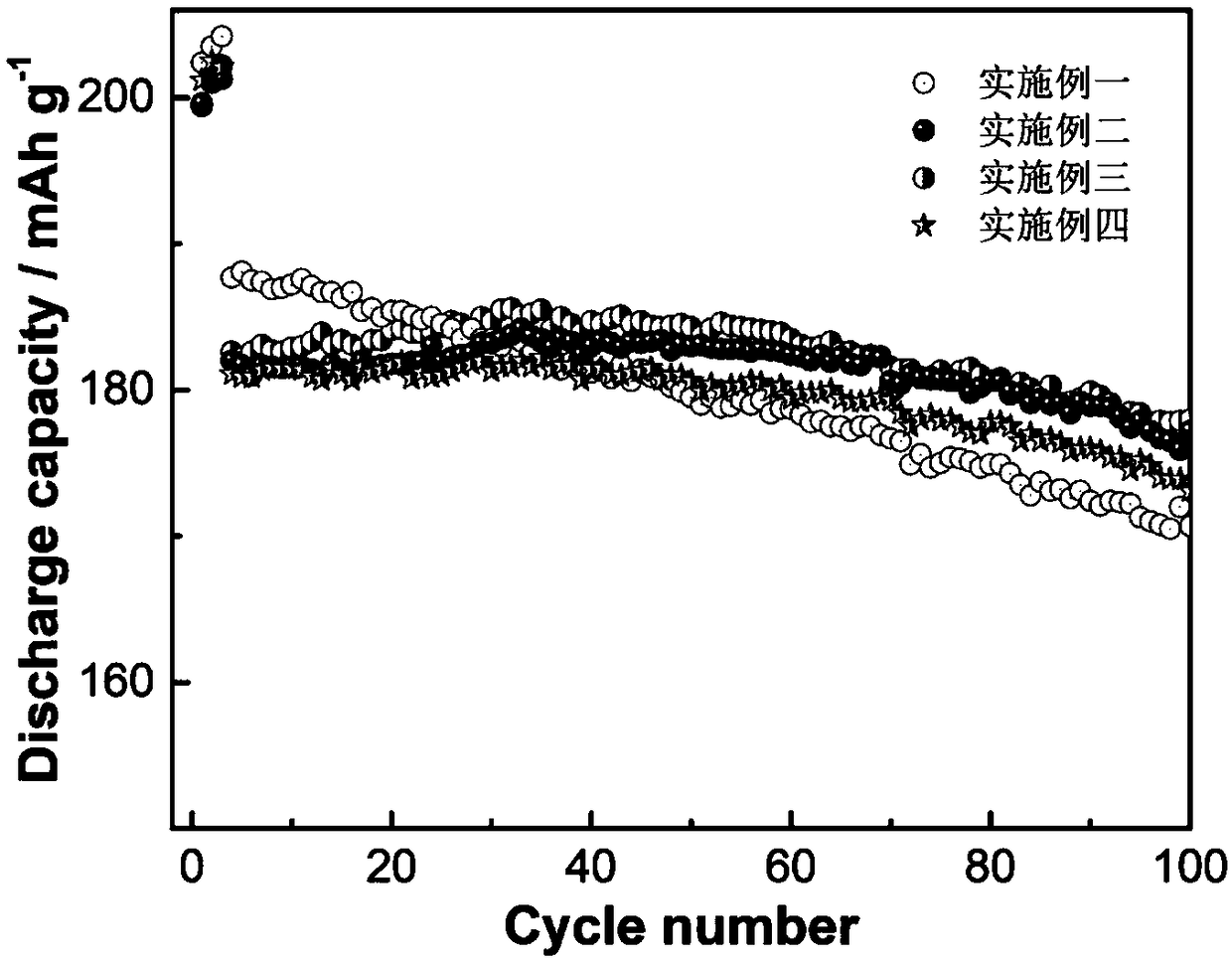

Embodiment 1

[0043] In a glove box filled with argon gas, DMC and EC were mixed with 5mL electrolyte at a volume ratio of 7:3, and lithium salt lithium hexafluorophosphate (LiPF 6 ), the concentration of the lithium salt was 1mol / L, stirred until the lithium salt was completely dissolved, and 2.5wt.% lithium difluorophosphate was added to obtain an electrolyte.

[0044] When making a battery, put the positive electrode material in the middle of the positive electrode shell, add a certain volume of 30 μL of electrolyte on the surface of the positive electrode material, and then add 60 μL of fluorine-containing solvent 1,1,2,2-tetrafluoroethyl-2,2 ,3,3-Tetrafluoropropyl ether (C 5 h 4 f 8 O) On the surface of the positive electrode material ternary material NCM622, the lithium salt additive is precipitated, and then add a layer of Celgard2500 diaphragm, negative electrode material lithium metal sheet, gasket, shrapnel, cover the negative electrode case, and seal the battery with a sealing ...

Embodiment 2

[0047] In a glove box filled with argon, mix DMC and PC with 5 mL of electrolyte at a volume ratio of 7:3, and slowly add lithium bistrifluoromethanesulfonylimide (LiTFSI) so that the concentration of lithium salt is 1 mol / L , stirred until the lithium salt was completely dissolved, and 2wt.% lithium difluorophosphate was added to obtain an electrolyte.

[0048] When making a battery, put the positive electrode material in the middle of the positive electrode shell, add a certain volume of 30 μL of electrolyte on the surface of the positive electrode material, and then add 45 μL of fluorine-containing solvent 1,1,2,2-tetrafluoroethyl-2,2 ,3,3-Tetrafluoropropyl ether (C 5 h 4 f 8 O) On the surface of the positive electrode material ternary material NCM622, the lithium salt additive is precipitated, and then add a layer of Celgard2500 diaphragm, negative electrode material lithium metal sheet, gasket, shrapnel, cover the negative electrode case, and seal the battery with a sea...

Embodiment 3

[0052] In a glove box filled with argon, mix EMC and PC with 5mL electrolyte at a volume ratio of 7:3, and slowly add lithium salt lithium bisfluorosulfonimide (LiFSI) to make the concentration of lithium salt 1mol / L , stirred until the lithium salt was completely dissolved, and 1wt.% lithium difluorophosphate was added to obtain an electrolyte.

[0053] When making a battery, put the positive electrode material in the middle of the positive electrode shell, add a certain volume of 30 μL of electrolyte on the surface of the positive electrode material, and then add 30 μL of fluorine-containing solvent 1,1,1,3,3,3-hexafluoroisopropyl methyl ether (C 4 h 4 f 6 O) On the surface of the positive electrode material ternary material NCM622, the lithium salt additive is precipitated, and then add a layer of Celgard2500 diaphragm, negative electrode material lithium metal sheet, gasket, shrapnel, cover the negative electrode case, and seal the battery with a sealing machine.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com